USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

* We use anti-corrosion steel mold to make this mold.

* By doing such, the mold can sustain PVC material’s corrosion when doing molding.

* Also, by doing such, such PVC pipe fitting parts can sustain high pressure using environment.

* Such pressure pipes parts which are produced from our mold can be used in potable water supply systems.

* Such pressure pipes parts which are produced from our mold are not suitable for long exposure to sunlight but give excellent chemical resistance.

PVC pipe fittings mould ( for high pressure and low-pressure ,for water supplying and water discharging) ,PVC is sometimes known as "Vinyl" in Europe and predominantly so in North America. "Vinyl" usually refers to certain specific flexible applications, such as flooring, decorative sheets and artificial leather,This chlorine gives PVC excellent fire resistance.

Nowadays people start to use PVC for pipe fitting because they are much cheaper and durable compared to metal ones

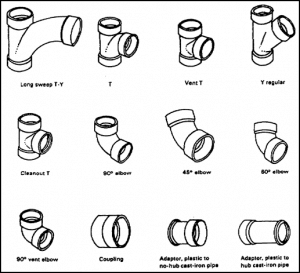

SWY MOULD can make several pipe fitting moulds

1. CPVC pipe fitting for high pressure

2. UPVC pipe fitting for water drainage

3. PVC belling pipe fitting mould (with collapsible cores for pressure water supply)

4. Electricity cable pipe fitting, built in-wall various PVC pipe fittings

The technical solutions for PVC pipe fitting moulding and PVC pipe fitting mould manufacturing. PVC is a kind of special material that needs a special injection moulding process.

The basic feature of PVC material

1. Hard PVC material low MFI

2. PVC with high corrosive

3. PVC with low-temperature melting

4. Easy decomposition

Design of plastic pipe mold

The design of the pipe fitting mould is an important step to improve the quality of the pipe fitting mould, including the selection of the pipe fitting mould material, the usability of the pipe fitting mould structure, the processability of the pipe fitting mould parts, and the convenience of the pipe fitting mould maintenance. The design of the pipe fittings should be reasonable, and the best structural scheme should be selected as much as possible. The designer of the pipe fittings must consider the technical requirements and structure of the pipe fittings to meet the technological and feasibility of the pipe mould manufacturing.

The advantages of SWY MOULD

1. Good steel with high hardness

2. Good accessories with high brightness

3. Good machining with high precise

4. In-time response on email, telephone calls

5. In-time supply the quotation and mould designs

6. In-time communication on the technical points

7. In-time sending pictures for the mould machining progress and mould finishing schedule

8. In-time mould test and sample delivery

9. In-time mould delivery

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Straight Cross Pipe Injection Molding Suppliers