USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Mold steel: S136

Mold cavity: 2

Runner type: cold runner

Gate type: side gate

Surface finish: cavity---SPI B3

core---600#Sandpaper

Mold Standard: DME

Mold type: two-plate mold

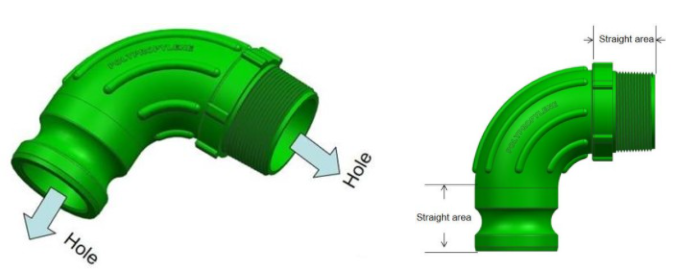

Part analysis of this mold

Although it's not a big guy, the structure characteristics have caused us some troubles.

There will be two straight sides on the finished product, the slide cannot slide out directly due to the bend in the product, this is why we have to design a special mold structure for releasing the mold. But finally, we solved all problems.

The design analysis of the mold

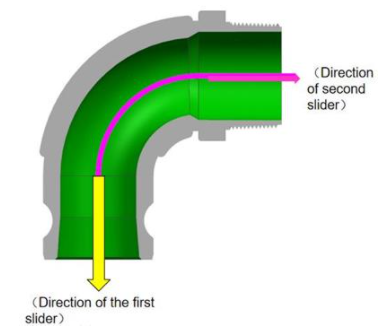

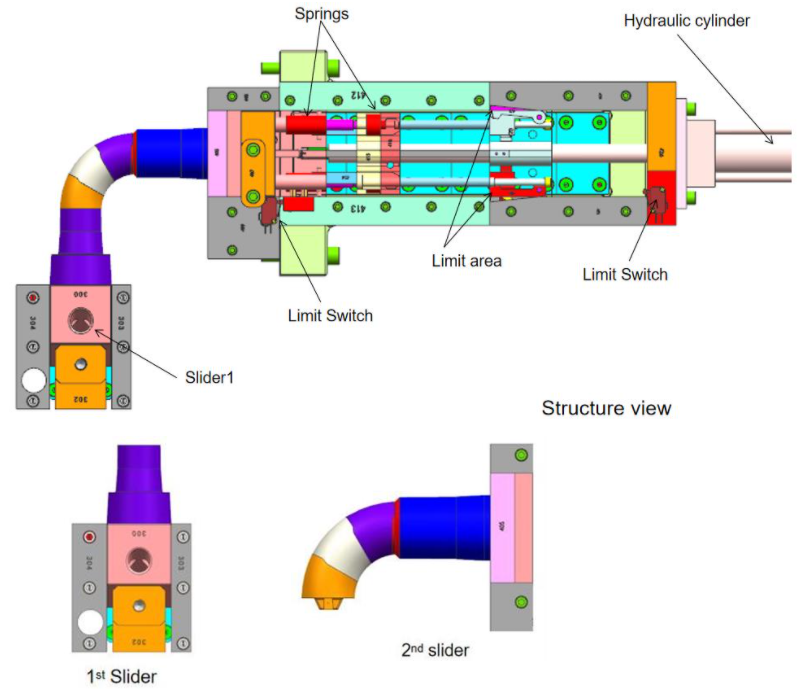

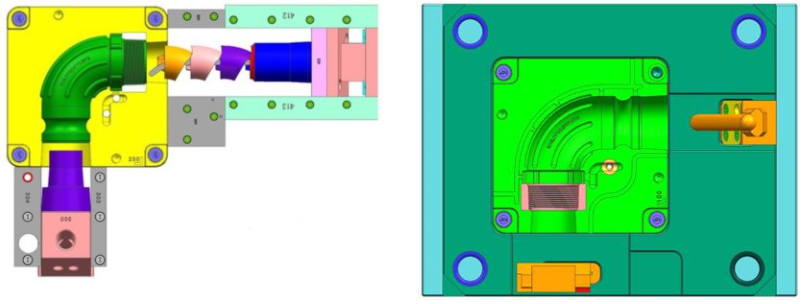

According to the product requirements, our engineering department designed an innovative mold structure to solve mold release. The mold will need two sliders for this product, as you can see in the image to the right, the first slider is only for the straight section, the second slider needs to go straight, and then rotate the core inserts out pf the part.

1. Mold slider structure

Now let's take a look at the overall structure of the slider:

2. Collapsible core

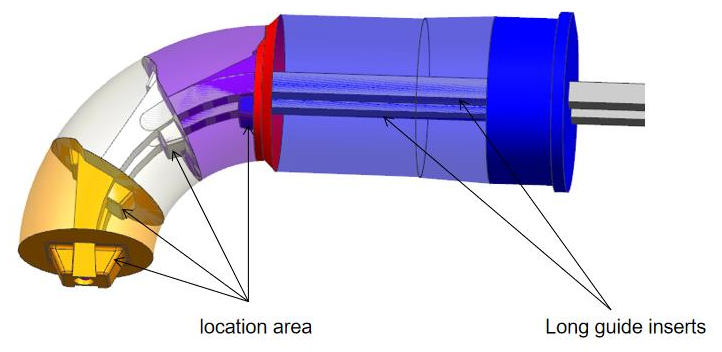

For the mold smoothly, we have to separate the second slider into 3 core inserts, see the below image shows.

In fact, this variant core structure is more like a chain. Therefore it is also called chain core structure.

To make the product release from the mold smoothly, SWY designed and manufactured three pivoting core inserts. It depends on the arc length of the elbow and it has two straight areas.

The only disadvantage of this structure is that the mold core can not carry cooling. Only used the method of external cooling.

3. Mold fixed and moving side

The slider comes out of view. We control the entry and exit of the slider through two sire ropes.

On the fixed side, the mold core contains a threaded insert.

What we can talk about is only a little, we reserve more details because the company needs. Thank you for your forgiveness. Maybe it's not the perfect solution, we welcome you to come to talk with SWY MOULD if you are interested.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mold For 90 Degrees Elbow Suppliers