USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

First mass production by SWY MOULD, then sending the mould and products together, later mass production by our customer

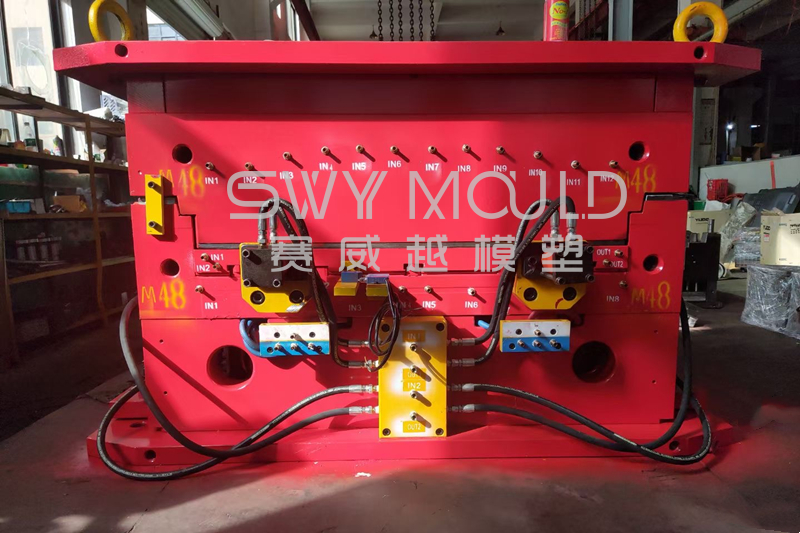

Upper and below two parts made into two mold

Mould steel: P20

Base material: 50#

Injection system: cold runner

Ejection system: picked by robot or hand

Shipping method: by container

T1 time: 55 working days

The basic parts of plastic injection mould

Every mould is different and has different components, but there are some standard components that we inspect on every mould by SWY MOULD.

For every customer who needs us for mass production, we will maintenance well for his mould.

The importance of mould maintenance

Proper mould maintenance is important to help us supply quality products and reduce downtime from potential mould-related issues. By getting ahead of issues before the mould is scheduled to run, we avoid delays from unscheduled downtime on the press. Our SWY also allows us to set targets during long production runs. By setting these targets, we can know when to pull the mould out for scheduled maintenance before something major happens, like producing parts out of specification, or before the mould breaks to a point of creating costly repairs.

1. General maintenance

Depending on the complexity of the mould, larger-scale general maintenance is usually done according to cycle count, or the number of times the mould has been run. Basic open-and-shut moulds without complex action receive general maintenance between 250,000 and 500,000 cycles. A mould with many moving parts requires a closer look, so we do general maintenance every 100,000 cycles.

We inspect the last shot of parts from the mould for damage or defects. If all is well, we go ahead and disassemble the mould completely. The mould plates are cleaned and inspected for signs of wear, vent depths are checked, and O-rings are replaced. Any part of the mould that is defective or damaged is repaired. If the mould is equipped with a hot runner, we check it for signs of leakage and inspect the condition of the components. Then, we reassemble the mould, run a thorough systems check, and ready it for production or storage.

2. Major maintenance

Every mould undergoes major preventative maintenance, between 500,000 and 1 million cycles. This process includes all of the steps done in general maintenance and takes a much more in-depth look. We measure the mould's alignment features, compare them to their baseline "new" condition, and replace them as necessary. All other components are measured to the original print dimensions and put back to new condition. We clean every water passage in the mould by removing all pipe plugs, baffles, and water fittings. If the mould cavity finish is degraded at all, we refurbish it. When all's said and done, we rebuild the mould in better-than-new conditions and put it back to work!

Service provided by SWY MOULD

1. Your inquiry related to our products or prices will be replied within 24hours

2. Well-trained and experienced staff to answer all your enquiries in fluent English.

3. Offering support to solve the problem in the application or selling period.

4. Competitive prices based on the same quality.

5. Guarantee samples quality same as mass production quality.

6. Welcome your 2D, 3D, and other drawings, we produce strictly according to your design or your request.OEM&ODM are accepted.

7. Not only manufacture mould but also supply product.

8. IF you are interested in our products, please contact us at any convenience. We'd like to tell you more about our products, meantime, you only need to give us your requirements in detail for your products, we can design and produce for you very well.

9. We warmly welcome your visit, as it is said to see is to believe if possible.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Tool Box Plastic Body Part Mould Suppliers