USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part size: 7*8mm

Plastic material: recycled plastic

Mould cavity: 24

Mould material: 2136 anti-corrosion

Steel treatment: vacuum hardening

Runner type: open type edge gate

Because our customer uses the recycled material, there will be impurities inside, so for the runner size, SWY Mould will make it larger to avoid the runner being blocked.

Working days: 3D scanning + design need 3 days; for mould making needs 40-50 days

What is a plastic rebar support chair?

Plastic rebar chair spacers are used to support rebar on a deck, which includes radial grounding, heavy-duty rebar laying, and beams. The wide base of these plastic rebar chair spacers prevents the chairs from tipping over. The design ensures the free flow of concrete and minimal contact with the concrete formwork.

Rebar chairs are specially designed components made for supporting rebars, which are embedded metal bars used to reinforce newly-poured concrete. Rebars are laid out in a crisscross grid pattern and are locked together with the rebar chairs before the fresh concrete is poured over them. This reinforcement is necessary when laying the foundation for a new building.

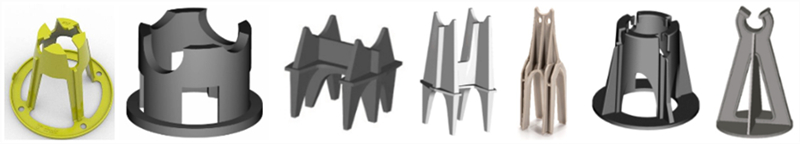

There are different shapes of rebar chairs, such as Anchor chairs, F-chairs, H-chairs 6 legs, H chairs 4 legs, tower chairs, mesh chairs, utility chairs, etc.

Picture shows:

Advantages of using plastic rebar chairs:

* High resistance to solvents, oils, and many acids

* Lightweight durable plastic lends to easier handling

* Fast and convenient snap-lock design saves time

* Eliminates tying at support points

* Low cost per unit

The usage of this plastic rebar support chair

Why using recycled material to produce?

Before mould testing, our customer sent us his own material to produce. The material is recycled PE.

The reason why using recycled material:

1. Decrease the plasticizing during the world. As there are many waste plastic and cause a serious problem to the world if there is any way can help the world decrease the pressure, it would be very well.

2. Save the cost. This kind of product needs a high quantity with a low price, so the investment of plastic moulds, need a long cycle time, but the raw material cost needs to be low.

Advantages of our SWY MOULD COMPANY

competitive price + excellent quality + advanced equipment + good management

1. Multiple surface treatments:

* Plastic Products (Polishing, Painting, Texturing, Silk Printing, etc.)

* Metal Products (Polishing, Plating, Anodizing, Zinc plating, Nickel plating, Powder coating, Chromed, Brushing, etc.)

2. Rich experience in plastic injection mould processing and manufacturing

3. 100% manufacturer, ensure quality and lead time better

4. Advanced equipment and skilled technicians to ensure more precision and good quality

5. Measuring equipment, including caliper, height gauge, horizon level, CMM, microscope, pressure gauge, magnifier, roughness tester, etc.

6. Warm service & good quality, we are dedicated to stable good quality, environment-friendly products, short delivery, and quick response

7. Provide one-stop service: design ⇒ prototype making ⇒ molding trial ⇒ production ⇒ packaging and assembly ⇒ shipping

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Mould Of Industrial H-Chair Rebar Support Suppliers