USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part size: dia-60*6mm

Plastic resin: HDPE

Mould steel: 2316 with heat treatment

Mould base: 60#

Mould cavity: 8

Runner system: cold runner

T1 days: 45 working days

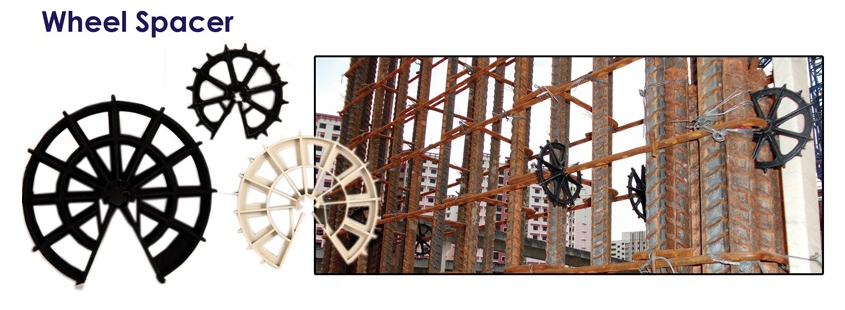

The plastic spacer wheel

The plastic spacer wheel is for concreting support for reinforcing mesh and bar. There are many various sizes of rebar spacer to meet the different demands of the building. The material of our construction concrete plastic spacer wheel is HDPE. Some are made by PP or PVC, all are decided by yourself which kind of material need to use.

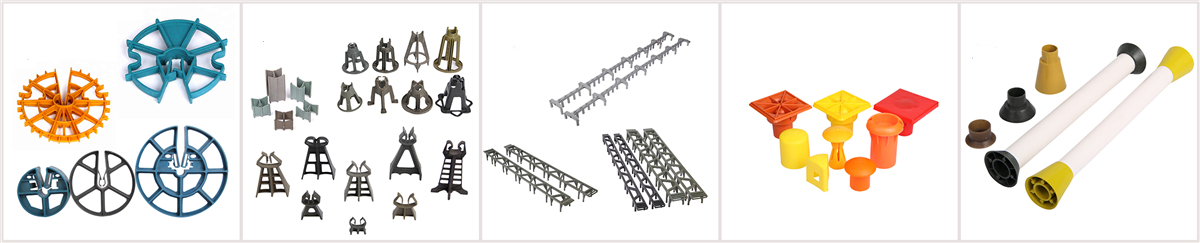

Different types of plastic rebar spacers

Plastic rebar spacers are widely used in the construction of basic concrete for concreting support for reinforcing mesh and bar. There are many various sizes and shapes of plastic spacer to meet the different demands of the building.

1. Plastic wheel spacer 2. Plastic rebar chair spacer 3. Plastic ladder spacer 4. Plastic rebar safety cap 5. Plastic sleeve with a plastic cone

No matter which kind of plastic rebar spacer you need to customize the injection moulds, sending us the sample or design, we will make satisfied moulds for you.

Here viewing some of the plastic rebar spacer moulds we made before:

As the common color used for this plastic wheel spacer is black, also some customers need to use recycled plastic material to produce, it easy to cause silver marks on the products.

Silver marks in injection molded parts include surface bubbles and internal pores. The main cause of defects in the interference of gases (mainly water vapor, decomposition gas, solvent gas, air). Here SWY MOULD would like to discuss with you some reasons why cause these silver marks.

Reasons for causing silver marks on plastic construction wheel spacer moulds

1. Injection molding machine part

* The barrel, the screw wears or the rubber head and the apron have a dead angle of material flow, which is decomposed by heat for a long time.

* If the heating system is out of control, causing the temperature to be too high and decomposed, check whether there are any problems with the heating elements such as thermocouples and heating coils. The screw is not designed properly, causing a decomposed or easy to bring into the air.

* Temperature, pressure, speed, back pressure, melt motor speed is set to be too high so cause decomposition, or pressure and speed are too low, injection mold time and pressure holding are insufficient, back pressure is too low, due to failure to obtain high pressure and density is insufficient, so that gas can’t be melted, thereby silver streaks appear. Appropriate temperature, pressure, speed, and time should be set and multi-stage injection mold speed should be used.

* The back pressure is low and the rotation speed is fast, so that the air enters the barrel, and enters the injection mold accompanying melt. When the period is too long, the melt is decomposed in the barrel due to excessive heat.

* The insufficient material, the feeding cushion is too large, the material temperature is too low or the injection mold temperature is too low, which affects the flow of the material and the injection molding pressure, and promotes the formation of bubbles.

2. Plastic mould part

* Poor exhaust.

* The frictional resistance of the runners, gates, and cavities in the injection mold is large, causing local overheating and decomposition.

* Unbalanced distribution of gates and cavities and the unreasonable cooling system will cause heat imbalance and local overheating or obstruction of air passages.

* The cooling passage leaks water and gets into the cavity.

3. Plastic raw material part

* The plastic has a large humidity, and the proportion of the added recycled materials is too large or contains harmful scraps (the scraps are easily decomposed), and the plastic should be sufficiently dried and the scraps should be eliminated.

* Moisture absorption from the atmosphere or moisture absorption from the colorant, so the coloring agent should also be dried. It is preferable to install a dryer on the machine.

* The amount of lubricant, stabilizer, etc. added to the plastic is excessive or unevenly mixed, or the plastic itself has a volatile solvent. Decomposition occurs when the mixed plastic is difficult to maintain heat.

* The plastic is contaminated and mixed with other plastics.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Mould Of Construction Spacer Wheel Suppliers