USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part features: round grid

Part size: 361.3*361.3*27mm

Mold steel: 718

Mold base: C50

Lead time: 55 days

Mold mass production by SWY MOULD

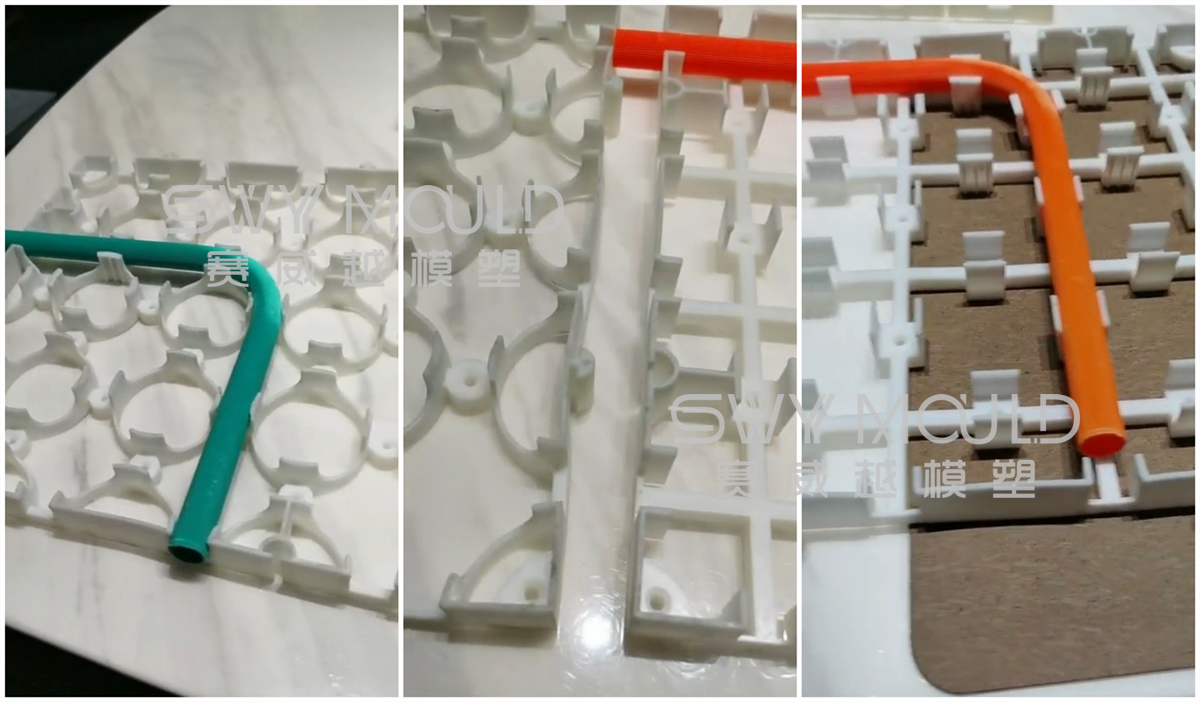

About the choice and features of plastic original samples

This mold is made some changes on the original samples. Before making the mold, our customer asked us to make 3D printing samples to check the feasibility. At first, there are two shapes of the grid, one is round and the other is square, after the customer checked the practicality of the two samples, decided to choose the round grid.

What is a mold trail?

Mold trial refers to, in the product development and manufacturing, the test injection step that is carried out after the mold making is completed and before the mass production. We need to pay attention to the following matters before the mold trial:

1. Learn about the relevant information on mold.

It is best to have the 3D or 2D design imagines of the mold, analyze it in detail, and get the mold technician to participate in the mold trail work.

2. First check its mechanical cooperation on the workbench.

Attention should be paid to whether there are scratches, missing parts, and looseness. Check if the die plate movement is correct and whether the water pipe and air pipe joints are leaky. If there is a limit to the die opening, mark it on the die. If the above action can be done before hanging the mold, which can avoid finding the problems when hanging the mold and then removing the mold, which causes the man-hour waste.

3. When it is determined that the various parts of the mold are okay, choose an appropriate trial-to-die injection machine. When selecting, attention should be paid to:

* What is the maximum injection volume of injection molding machines?

* Whether the internal size of the pull rod is enough to place the mold?

* Whether the maximum movement schedule of the movable template meets the requirements?

* Whether other related tools and accessories for mold trail are fully prepared.

After confirming everything have no problem, the next step is to hang the mold. When hanging, pay attention to that all the clamping plates on the lock and the hanging fish can't be got off, which avoids clamping mold plate losing or breaking, so that makes the mold drop.

After the mold is installed, check carefully the mechanical action of each part of the mold, such as skateboard, thimbles, tooth structure, and limit switch. Pay attention to whether the nozzle and feed mouth are aligned.

The next step is to pay attention to the action of the compound die. At this time, the mode pressure should be lowered. In the compound die action of manual and low-speed, pay attention to see and hear whether there is any unsmooth movement and abnormal sound.

4. Increase the injection mold temperature.

According to the performance of the raw material and the size of the mold, choose the appropriate mold temperature control machine to increase the mold temperature up to the required temperature of production. Check one more time the action of each part after mold temperature is increased. Because the steel may cause the phenomenon of card mold after thermal expansion, it is necessary to pay attention to the sliding of each part, so as to avoid tension and vibration.

5. If there is no experimental planning law in the factory, we suggest that only one condition can be adjusted at a time when adjusting the test mode condition, so as to distinguish the effect of the change of a single condition on the finished product.

6. According to the different raw materials, do moderate baking for adopted raw material.

7. Try to use the same raw material as possible when trying mold and do mass production.

8. Don’t only try the mold, if there is a color requirement, can arrange to test the color at the same time.

9. Internal force and other problems often affect the secondary processing, so adjust the closing mold pressure and have several times of movement after mold trail and forming products is stable, to see if there is no clamping pressure inequality, so as to avoid burrs and mold deformation.

After the above steps are checked, lower the closing mold speed and pressure, the safety buckle and the ejection stroke are set, and then the normal closing mold and the closing mold speed are adjusted. If related to the limit switch of maximum stroke, the mold opening stroke should be adjusted to be short, and the high-speed mold opening action should be cut before the maximum stroke of this mold opening. This is because in the entire mold opening stroke during the mold loading, the high-speed stroke is longer than the low-speed stroke. The mechanical ejector rod on the plastic machine must also be adjusted to act after full-speed mold-opening action, which avoids the deformation of the ejector plate or stripper plate due to force.

Check the following items before making the first mold shot:

* Whether the feeding trip too long or short?

*Whether the pressure too high or low?

* Whether filling speed too fast or slow?

* Whether processing cycle too long or short?

To prevent short shots, fractures, deformations, burrs, and even mold damage. If the processing cycle is too short, the thimble will top the finished product or peel the ring to crush the finished product. This type of situation may take you two or three hours to remove the finished product.

If the processing cycle is too long, the weak part of the mold core may be broken due to shrinkage of the rubber material. Of course, you cannot expect any problems that may occur during the trial process, but full consideration and timely measures will help you avoid serious and costly losses.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Decoration Conduit Holder Injection Mold Suppliers