USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Spacer size: 2.5*2.5*23mm

Raw material: HDPE

Mould steel: P20

Mould cavity: 216

Base material: C50

Injection system: cold runner

Ejector system: ejector pin in the middle

Lead time: 35 days

What are tile spacers?

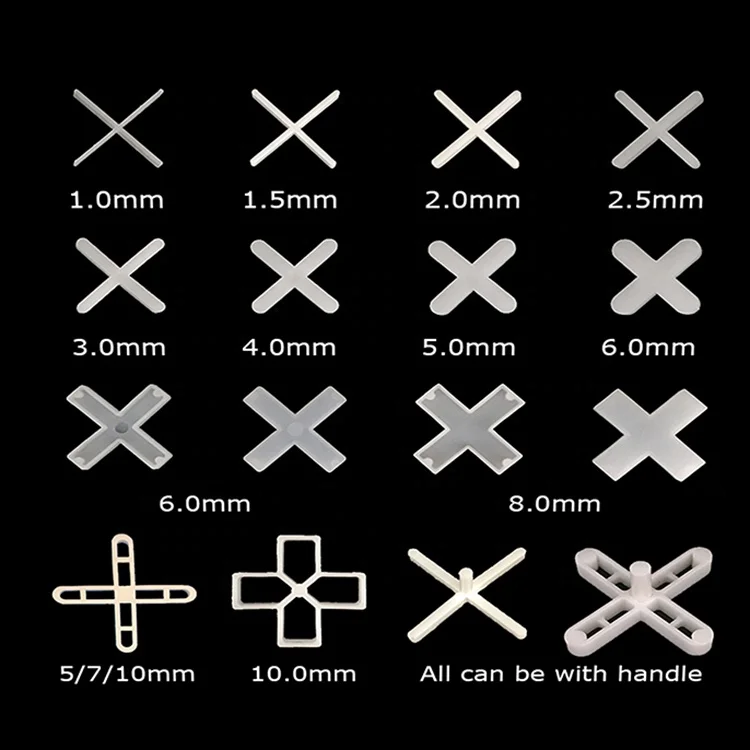

Tile spacers are small, plastic objects that are usually built in either “T” or a cross shape. They come in quite a few sizes, ranging from 1mm to 10mm.

They are used to maintain a consistent space or “gap” between your tiles when installing them on the adhesive. This allows for an even finish when it’s time to grout your tiles.

To use them, you place spacers at each corner of your tiles as you’re laying them down, and you push the tiles together until the spacer is contacting each corner. They’re removed shortly after you finish the tile installation and can usually be reused in a future project.

Our customer sent us his product specifications. For the first time, he asked us to make a 2.5mm mold specification.

For such a small size mould, the machining is very important to ensure the size precision.

Factors need to consider in plastic cross ceramic tile spacer injection mould making

1. Mould steel selection

The material for making plastic injection molds should be high-quality alloy tool steel with high mechanical properties and low thermal creep. The mold material for making the cavity and runner should be selected through strict heat treatment with high hardness, good wear resistance, strong corrosion-resistance, and thermal deformation resistance. At the same time, the difficulty and economy of mechanical processing and electrical processing should also be considered. In order to prevent the occurrence of aging changes and change the dimensional accuracy of plastic injection molds, it is necessary to specify tempering treatment or low-temperature treatment to reduce the residual tissue of the heat treatment of the mold material when designing the mold.

2. Mould design considering

* The size of the mold base, the wall thickness of the cavity; the relationship between the life and the manufacturing cost, and the impact of the size of the injection molding machine on the investment cost as well as production cost.

* The strength of the insert and the reliability of its placement.

* Try to avoid individual parts or a certain position in the cavity from becoming a weak link.

* The guidepost plays an important role in the process of moving the mold, so its strength and wear resistance must be considered. Other material selection, processing, and assembly mainly consider the contradictory relationship between cost and quality, which will not be repeated here.

* Before the precision plastic mold is opened, the toggle lever-type has not released the clamping force, especially when it is overloaded, the core has not been restored, and the plastic has cooled. Therefore, the friction between metal and plastic greatly increases core wear.

* When the mold is opened, the toggle lever-type will produce vibration due to the sudden release of the clamping force, which will aggravate the damage of some stressed parts.

3. Mould machining control

To maintain the accuracy of plastic injection moulds under injection pressure and clamping force, the feasibility of grinding, grinding, and polishing the cavity parts must be considered when designing the mold structure. Although the plastic injection mold cavity and core processing have reached high precision requirements, the shrinkage rate is the same as expected. However, due to the center offset during molding, the relevant dimensions of the inner and outer sides of the molded product are difficult to meet the design requirements of plastic parts. To maintain the dimensional accuracy of the front and rear mold cavities on the parting surface, in addition to setting the common guide pillar and guide sleeve centering, the positioning blocks such as conical positioning pin or wedge block must be added to ensure the accurate and reliable positioning of the plastic injection mold.

Viewing plastic cross ceramic tile spacer injection mould made by SWY MOULD

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Cross Ceramic Tile Spacer Injection Mould Suppliers