USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Pallet Size: 1200x1200x150mm

Pallet Material: HDPE MFI 8

Product description: Dual-layer pallet with 4 slides

Mold Size: 1800x1800x1100mm

Suitable machine: 2000T Dakumar machine

Mold material: DIN 1.2311

Runner system: 16 points Anole hot runner gate

Ejection system: ejector pin and ejecting block

Mold running: ejector pin+slide system

Injection cycle time: 95 seconds

Matt plastic pallet mold features

Complex mold structure, fine cooling system design, ANOLE hot runner professional filter system design, suitable for high speed recycled material injection production Stroke switch controls ejection process precisely, oil and water integrator is more convenient for application and operation, copper guide bush, abrasion resistance and prolong the mold life.

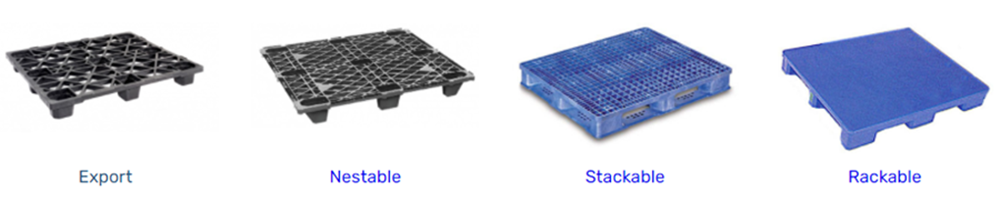

Plastic pallets are an exceptional addition to any business which does a lot of shipping. Not only are they sturdy and dependable, but they’re ideal for quickly transporting a large amount of product at once; they’re great for moving onto trucks or train cars in rapid succession.

They also come in a far wider variety than wooden pallets do. There are rackable or stackable pallets that are optimized for easy storage. Even fast-locking models can snap into place beside one another to create custom-sized pallets and fire-retardant pallets that are ideal for high-heat environments.

How are matt plastic pallets made?

Plastic pallets are manufactured at an injection molding facility. But how do these individual designs come into existence, from planning to production? The path is complex but entirely necessary to ensure that the product is a success.

The main process of pallet production:

1. pallet design

During the process of designing a plastic pallet, many things come into consideration. Things such as the purpose of the pallet and how it will be transported, stored, what industry will use the pallet.

All these considerations impact and contribute to the design, material, weight, and durability of a pallet. Once the design for the plastic pallet is in place, the mold will be made to make that exact design.

2. pallet molding

High-pressure injection molding is the process in which virgin plastic and colorants are mixed and melted together in a barrel or mixing chamber, before being injected into the mold.

3. the final production of the pallet

When using high-pressure injection molding to create large quantities of high-quality, plastic pallets, production times become more efficient. By increasing production speed and being able to produce plastic pallets in mass quantities as fast as possible, it reduces the risk of being scarce. Also, with a production process such as this, it is easy to customize and change designs and molds, making it possible to produce pallets for even the most specific needs.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Matts Plastic Pallet Mold Suppliers