USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Large one size: 30*30*30mm

Small one size: 26*26*26mm

Plastic resin: HDPE

Mold steel: 2316 with heat treatment

Mold cavity: 8

Runner system: cold runner

Gate system: submarine gate

Working mode: drop automatically

Guideline to use plastic rebar chairs/support spacers

1. Selection of plastic rebar chairs

Before using the plastic bar chairs, the users must make sure the requirements of the thickness of concrete cover are regulated in the design. In case, there is no instruction in the design, the user must refer to the current regulations. The selection of plastic spacer should be implemented in the following sequence:

* Identify the type of structure

In general, most of all concrete spacers can be used in various structures and installation positions. However, some spacers are specially designed with certain advantages for a particular type of structure. Consequently, a selection of the right spacer will bring the advantage in the technical aspect, the convenience in construction, and reduce the cost for the project as well. Some types of plastic spacer are designed for bottom mesh, top mesh, steelwork of columns/wall, the beam ends…

* Identify the surface supporting the bar chairs

The load-bearing capacity of the foundation or formwork is decisive to the selection of the bar chair. In general, if the surfaces supporting the bar chairs are firm formwork or bedding concrete, the bar chairs will contact their supporting surfaces on the minimum areas. This is the common design for plastic bar chairs of the type “ A-shaped”, ”H shapes”, circular shape, rectangular-shaped…

In the case where the supporting surface is not firm, such as soil, stone base, we must use the bar chairs with their base areas large enough to distribute the load during the construction onto the ground and ensure the bar chair as well as the rebar they are supporting, will not be settled.

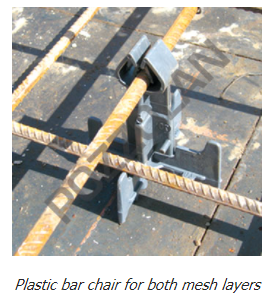

* Identify the layer of mesh

For supporting the bottom mesh layer, we can use any kind of plastic bar chair with a suitable height. However, if using the bar chair for the upper mesh layer, we should consider using the bar chair with a large base, such as a cone-shaped bar chair, which will avoid their turning over during the concreting work.

Some rebar chair products are designed for both bottom and top mesh.

* Determine the binding requirement with steel rebar

The plastic spacers directly bind the steel rebar with the elastic clip details. Depend on the requirement, the user will make a decision whether to use the plastic spacer with a clip or not.

To the reinforcement cage of footings, beams, slabs are placed on the bar chairs and shall not be moved during the construction, we do not need to use the bar chair with clips. However, in case that the reinforcement cage of structures is removable, such as bore pile, precast structures…or they can be displaced during the construction by the equipment, workers…the user should select the spacer with clip to ensure them will not be lost during the construction.

* To determine the concrete cover thickness

This is the main parameter of the bar chair product. The height of bar chairs are commonly designed with the interval of 5 or 10mm, depend on the type of product.

* To identify the rebar diameter

The bar chair is generally designed for a range of diameters from small to large. The user must select the right diameter of the bar chair, especially with the clip-on bar chair. The bar chairs with the wrong diameter of the clip will not able to fit the steel bars during installation.

2. Installation of plastic bar chair

* Check the steel rebars have been correctly installed and completed.

* Check the right bar chair products for each structure.

* To the reinforcement of beam or slab

Raise the steel cages for a gap between steel and formwork then place the bar chairs underneath; Adjust the position of bar chairs in ensuring good contact with the supporting surface.

* To the rebar of column or wall

Determine the height, spacing suitable for installation of the plastic spacer; adjust the wheels by turning them to the right position to obtain good contact with the formwork.

* If using the clip-on or wheel rebar chairs, the user pushes the bar chairs into the steel rebar or vice versa until the steel rebar reaches the inside face of the bar chairs.

* The distance of the rebar chairs will comply with the requirement of the designer.

What is high-density polyethylene?

High-density polyethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most versatile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large strength-to-density ratio, HDPE plastic has a high-impact resistance and melting point.

The benefits of HDPE material

Industrial-grade, FDA, NSF, and USDA-approved food-quality high-density polyethylene (HDPE) boards are engineered to be low maintenance, safe, and long-lasting. Their textured surface provides a grip to hold food safely.

Additional benefits include all of the following:

1. Easily meltable and moldable

One of the primary benefits of this plastic material comes from its inherent malleability. With this in mind, HDPE in particular excels. Thanks to a high melting point, HDPE remains rigid until very high temperatures. However, once it’s reached its melting point, the plastic material can be quickly and efficiently molded for use across a variety of unique applications including cutting boards, detergent bottles, milk jugs, food storage containers, corrosion-resistant piping, geomembranes, plastic lumber, and so much more.

2. Corrosion resistance

HDPE resists mold, mildew, and rotting, making it the ideal material for underground piping used to deliver water. Long-lasting and weather-resistant, HDPE can be sterilized by boiling, making it an ideal material for food and beverage containers. Additionally, HDPE can withstand most strong mineral acids and bases and has excellent resistance to naturally occurring chemicals found in soil. Moreover, the material is virtually impervious to most common chemicals, water, solvents, acids, detergents, and cleaning fluids.

3. Large strength to density ratio

The density of HDPE can range from 0.93 to 0.97 g, although the density of HDPE is only marginally higher than LDPE (low-density polyethylene). However, when under the microscope, HDPE’s linear structure means the material has little branching, which offers it stronger intermolecular forces and tensile strength than LDPE. It’s for this reason that a 60-gram HDPE container can safely carry over a gallon of liquid or roughly eight pounds of weight.

4. Easily recycled

Considering how much plastic we use in our day-to-day lives, one of the most important factors when deciding on the material is plastic recycling. Fortunately, HDPE plastic is easily recyclable, helping keep non-biodegradable waste out of landfills, while helping reduce plastic production by up to 50 percent! If you’re looking for a cost-effective, environmentally responsible material, HDPE may be the plastic for you.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mold Of Plastic Rebar Reinforcing Chairs Suppliers