USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Pot Material: PP

Core and Cavity: 2738

Mold Base: 50#

Cooling System: high quality circulating water design to improve product effectiveness and reduce your cost

Middle Treatment: thermomechanical treatment to improve hardness

Post Treatment: nitride treatment with low temperature and little deformation. It has high hardness without quenching, more than HV850, increased wear resistance

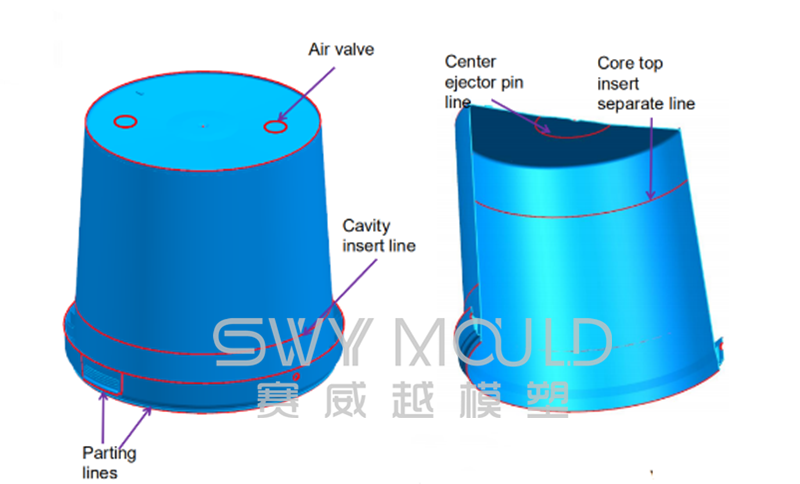

Design for plastic paint pot mold

Whether you have your own design ready for tooling or you need us to take you through the design process, SWY MOULD is here to offer our advice, based on years of experience in the industry. Injection molding design is done right, from initial concept through to final design.

1. Initial concept

Whatever the product you require is, it all starts with a design concept. The concept is planned and crafted into a functional product design.

2. Material selection

We pride ourselves on our expert knowledge of materials, allowing us to find the perfect material for your product and requirements.

3. 3D modeling

To ensure the design is fit for purpose, we produce 3D models in the house to show you and ensure that the design is right for you.

4. Final design

Final designs are produced for your product following the previous stages, creating a product that is robust and appropriate for use.

Improve stiffness of the bucket

The plastic is relatively flexible, and the bucket sometimes needs a large load capacity, so various measures for improving the rigidity should be adopted in the structure.

1. Add reinforcement

Reinforcement can enhance the strength and rigidity of the bucket. The basic requirements for the ribs are: the number should be more, the wall thickness should be thin, the height should be short, and the slope should be sufficient. The bottom of the rib should be a circular arc transition. The direction of the rib should be consistent with the flow direction to improve the plastic toughness.

2. Improve the shape

The box-shaped bucket is mostly rectangular thin-walled parts, which are easy to be deformed. Various reinforcement measures should be taken to slightly extend the four sidewalls of the bucket to improve the rigidity; it is a strip shape on the sidewall to prevent distortion. Enhancement; edge reinforcement at the edge of the bucket to prevent deformation of the mouth; bottom reinforcement at the bottom of the bucket designed in a corrugated, arched shape.

3. Reasonable support

The bottom area of the box-shaped bucket is large, but it is unreasonable to use the whole bottom surface as the support. Because the bottom is slightly curved, it is not flat. Therefore, the surface support should be changed into line support or point support, and the convex side support (ie, the line support); raised foot support (ie point support); the height of the protrusion is generally 0. 3 ~ 0. 5mm.

4. Corner

The corner is the intersection of two faces or three faces. Regardless of the shape of the bucket, the intersection of the faces must be rounded, which can greatly improve the rigidity of the bucket and improve the plastic filling model.

Demolding slope

In order to facilitate the demolding of the molded part, a suitable draft angle must be considered when designing the bucket. The draft is too small, the demolding is difficult, and the surface of the bucket is damaged; if it is too large, the dimensional accuracy is affected.

The draft angle varies depending on the shape of the plastic part, the type of plastic, the mold structure, the surface roughness, the molding method, and the like. Generally speaking, the commonly used slope of the plastic part along the demolding direction is 1o~1.5o, and the minimum is not less than 0.5o.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Paint Pot Injection Mold Suppliers