USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Egg tray capacity: 30 pieces of eggs

Part size: 300*300*50mm

Raw material: HDPE

Mold steel: P20

Mold base: C50

Injection system: cold runner point gate

Mold features: automatic dropped

Mold size: 400*400*365mm

Mold weight: 385KG

Customer's machine tonnage: 140T

Plastic egg tray description

1. Light and convenient to transport;

2. Good sealing property;

3. Plastic egg trays meet with environmental green packaging requirements;

4. Be suitable for any grotesque goods packaging;

5. Plastic egg trays can make the goods transparent, elegant, attractive, and easy to sell.

That's why many people use plastic material to produce egg trays. Also, our customers catch this business opportunity and let SWY MOULD make this egg tray mold.

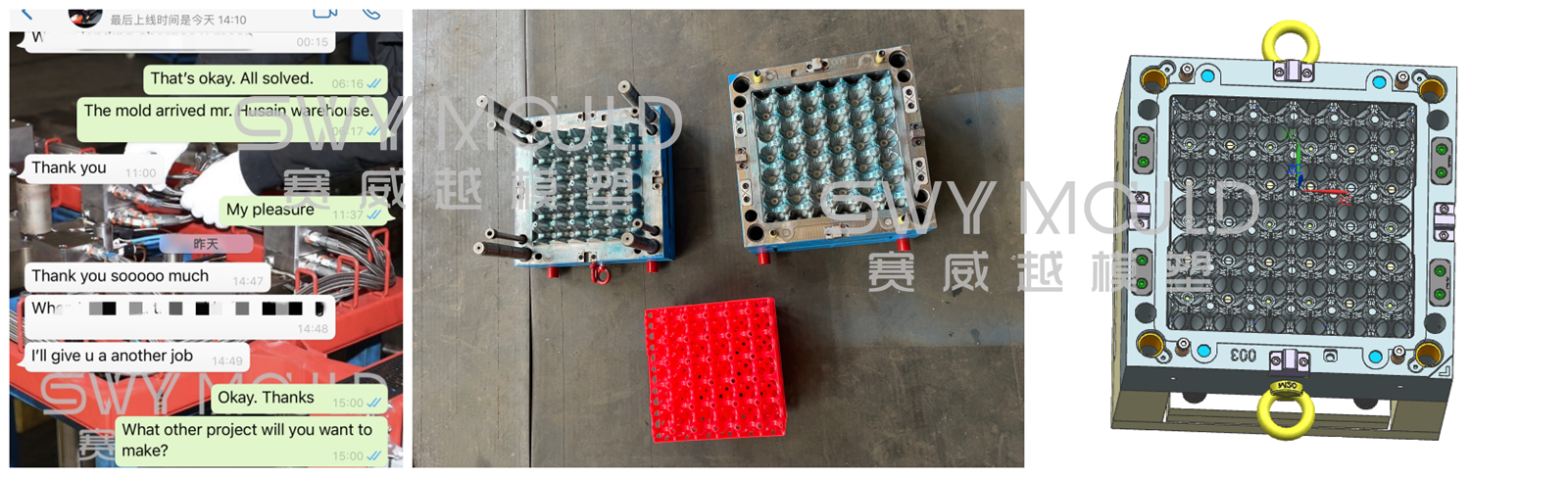

Feedback from SWY customer

Process conditions of 30 cells plastic egg tray injection mold

1. Drying treatment: Drying is usually not required unless stored improperly. If drying is required, the recommended drying conditions are 80℃, 2-3 hours.

2. Melting temperature: 180-280℃.

3. The upper limit for the flame retardant material is 250℃.

4. Mold temperature: 40-50℃.

5. Injection pressure: 200-600bar

The raw material of HDPE

Also known as polyethylene high density (PEHD), HDPE is a unique thermoplastic distinguished by its strength.

HDPE is extremely durable with multiple applications. Recent trends show a growing preference toward plastics for all packaging. The ease with which these materials can be recycled by the individual consumer protects the environment and increases their desirability.

HDPE is harder & more rigid than low-density polyethylene sheets and has a higher tensile strength. It is three times better in compressive strength tests. Stronger and more opaque than standard forms of polyethylene, it can act as a barrier against moisture and remains solid at room temperature alongside displaying UV-resistant attributes that block out harmful rays from the sun.

Additionally, it proves environmentally friendly during its production and use by a consumer with no leaking of toxic chemicals. Its thermoplastic characteristic makes HDPE easily recyclable as it can be melted down into liquid form and it is much more commonly recycled than its other polyethylene counterpart, LDPE.

Advantages of HDPE material:

1. Excellent durability in both hot and cold temperatures

2. Impervious to chemicals

3. Flexible scores with exceptionally long lives

4. Stability in outdoor applications

5. Variety of colors, thickness, and textures

6. Accepts numerous decorating techniques and enhances unique graphic designs

7. FDA approved

8. Environmentally friendly in production

9. Recyclable for use in secondary applications or producing high-energy fuels

10. CPSIA compliant

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM 30 Cells Plastic Egg Tray Injection Mold Suppliers