USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Mould cavity: double

Steel for cavity & core: 718

Mold base: C50

Plastic material: PS

Runner: hot runner

Lead time: 50 days

Mold shot life: 3 million shots

Injection molding machine: 280T

For making the best quality plastic cap mold, we request hard mold steel and high-grade mold standard component. Usually, S136,2316, H13, 4Cr13, 3Cr13 are widely used for producing cap mold. But sometimes we found some clients ask for P20,718 this kind of pre-harden steel for cap mold, to be honest, we don’t suggest this mold steel. Because in order to achieve 48-52HRC hardness, mold steel needs vacuum hardening and quenching treatment, but P20, 718 is not hardened enough, easily get damage. Lots of cap molds need a hot runner system. We always use the best quality hot runner. We also cooperate with YUDO, Master, DME, HUSKY, HASCO these famous hot runner brands as per client requirements.

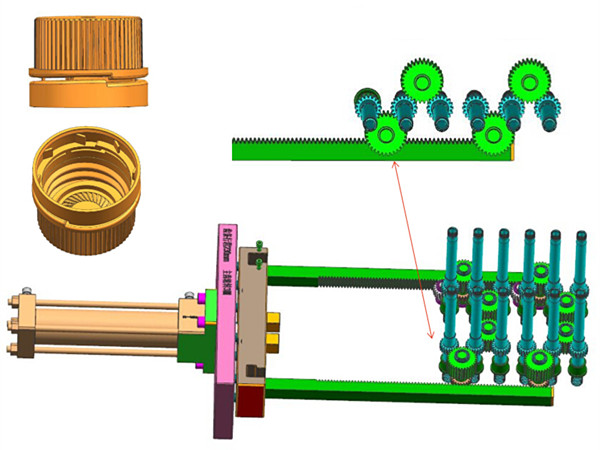

Plastic cap mould requests a high-quality hot runner system, choosing a reliable hot runner supplier is very important. We only cooperate with the best quality Chinese hot runner brands/companies. When firstly seeing a capped sample or cap drawing, our engineer immediately knows which ejector system available for that cap mould. For making cap mould, stripping plate ejector and unscrewing ejector are normal ejector system and applicable to almost plastic cap moulds. Most flip-top cap mould(shampoo cap mould, lotion cap mould, etc), pharmaceutical cap mould, cosmetic cap mould(tube cap mould, etc) all need an unscrewing ejector system.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Portable Water Bottle Plastic Cap Mould Suppliers