USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: PP

Mold steel: 718

Mold base: C45

Injection system: hot runner 1 drop

Ejection system: ejection pin + air venting

Mold size: 357*357*244mm

Mold weight: 160kg

Lead time: 35 days

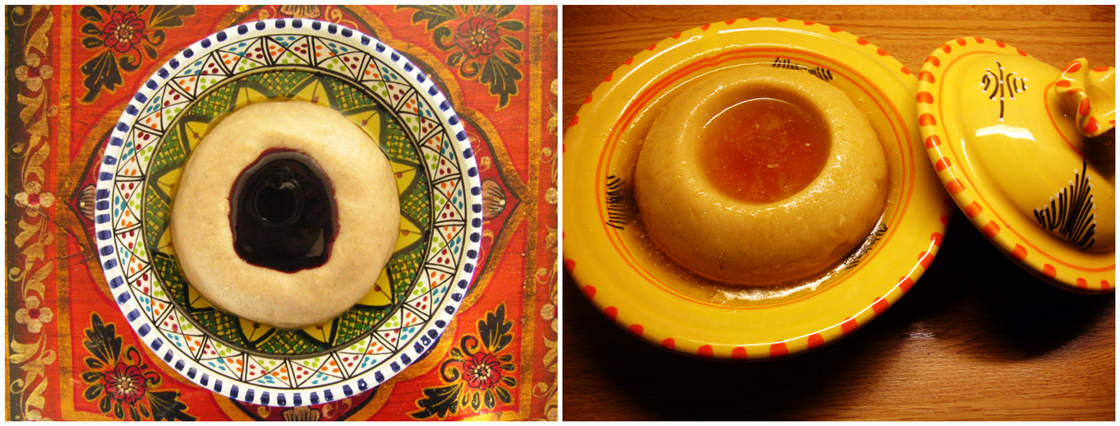

What's Asida and the usage of this round bowl

Asida, also called Aseeda, is a dish made of a cooked wheat flour lump of dough, usually with added butter or honey. It is a simple yet rich dish, usually eaten by hand, often eaten during religious holidays.

There is a difference on the bottom with other bowls, attached is the usage of this special bowl.

Ejection system in plastic injection mold

1. Ejector position

Ejected 10 – 15mm away from the edge of molding product (controlled by the retainer plate)

2. Ejection types

* Pin Ejector

* Blade Ejector

* Ejector Sleeve

* Stripper Bar Ejector

* Stripper Plate Ejector

* Lifter

* Air Ejector

3. Basic ejection requirements

* Product evenly ejected without ejection marks, unbroken and in shape;

* Main ejection parts: walls, ribs, holes, and bars;

* Set a standstill locking where the gradient or slope is slight;

* Add skid-proof stripes where the gradient is steep;

* The pin is level with or 0.2mm higher than the parting surface;

* The interval between ejector pins needs to be an integer;

* Ejector pin is at least 1mm away from the parting surface; if the parting surface is higher than 30mm, it should be at least 2mm away from the edge; if the parting surface is higher than 60mm, it should be at least 3mm away from the edge;

* Set a 0.5mm clearance between ejector pin and ejector plate & B plate;

* Set a 20mm, 30mm, and 35mm clearance between ejector pin and parting surface for small, medium, and large size molds;

* Better more than less, better large than small.

Hot runner system in plastic bowl injection mold

Thanks to its outstanding strengths, the hot runner mold has possessed a wide application.

1. Short cycle time

Without a runner system controlling the cooling time, newly formed plastic parts could be ejected as soon as they are solidified. Therefore, many plastic container injection moldings' cycle life is shorter than 5 seconds.

2. Reducing plastic waste

Without a cold runner system, there is no wasted plastic material generated during the hot runner mold's manufacturing.

3. Improved mold quality

Gate of hot runner mold is of high quality, which provides small residual stress after demolding and a small component deformation.

4. Finished plastic parts are manufactured once undergoing hot runner molding. No need for gate trimming and reprocessing in the cold runner system. Therefore, it accelerates automatic production.

Plastic bowl mold quality control in SWY

1. Plastic mold quality management method

Each process of plastic mold fabrication must be in strict accordance with the drawings, process requirements, provide injection mold workpiece, fitter through grinding, adjustment, confirmation to complete the mold assembly in accordance with ISO quality system stipulations.

2. Processing quality control methods

SWY team leaders have a comprehensive understanding of the plastic mold and part, with high skills, a sense of responsibility, and initiative.

Each monitor will guide the complex workpiece before processing according to the difficulty of the work, and clearly show the staff where the key points need to be paid attention to and make marks. Only after measurement confirmation of each process can the molded workpiece can be transferred to the next process.

3. Responsibilities of each process

The work of processing is to process the mold according to the requirements of the drawings.

On the premise of doing a good job in this process, to provide convenience for other processes.

4. Process key quality problem points and countermeasures in SWY

* Mold design problem point and countermeasures

* Mold CNC machining problem point and countermeasures

* EDM (Electrical spark) problem point and countermeasures

* Wire cutting problem points and countermeasures

* Fitter problem points and countermeasures

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Round Asida Bowl Injection Mold Suppliers