USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part material: PC

Can't load the high-temperature things

Mould & base steel: 718 & C50

Cheap steel way for this mould as our client choose with final treatment to HRC48-52 degree for core and cavity

Mould cavity: single

This can be designed depending on the client's injection machine

Cycle time: 18 Sec

We test in china on 120Ton normal injection machine

Leading time: 1st sample time need about 7 weeks after received the deposit and confirmed moulds design

Injection molding machines can produce plastic parts for rigid walls such as plastic jars and plastic containers. There is minimal waste in injection molding as the scrap can be recycled again. Being an injection molding manufacturer of plastic jars, we do all we can to reduce waste in and throughout the manufacturing process.

How does injection molding working?

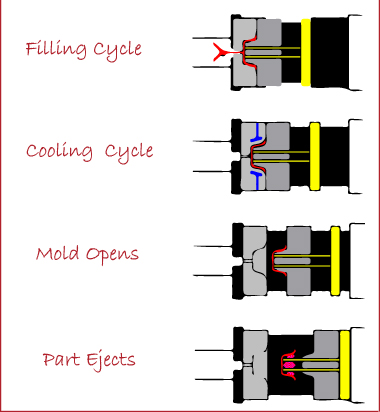

Injection molding manufacturers produce high numbers of plastic parts with high quality, very fast. Material is fed into a heated barrel where it is also melted. When smooth enough, the material is injected through a nozzle under pressure (filling cycle) to fill a mold cavity and then cools off (cooling cycle). Thereafter, the mould opens and the part ejects.

Characteristics of injection molding

1. Tool = Mould

2. Plastic material is melted and injected into the mould, after cooling the component is ejected from the mould

3. Process = Cycle time (each time mould is filled, cooled and component is ejected)

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Jar Mould With Handle Suppliers