USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

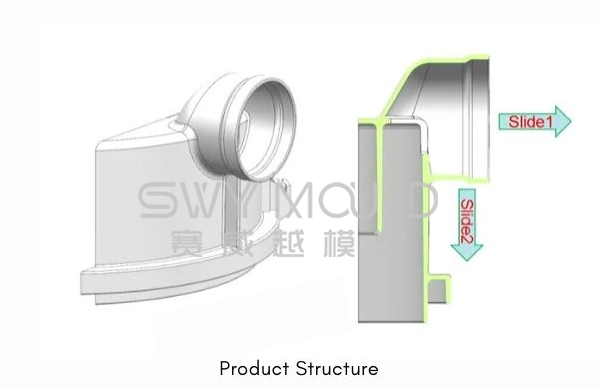

Part material: PP

Details: pattern on the surface

Mold material: P20

Base steel: C45

Mold cavity: single

Injection system: cold runner

Ejection system: slider core pulling + direct ejecting

Lead time: 45 working days

For this mold, the important thing is how to demolding easily, for there are many rotary lines on the surface, so when designing the mold, our engineer considers using a sider core pulling system plus direct ejecting to eject the product successfully.

Viewing our mold testing

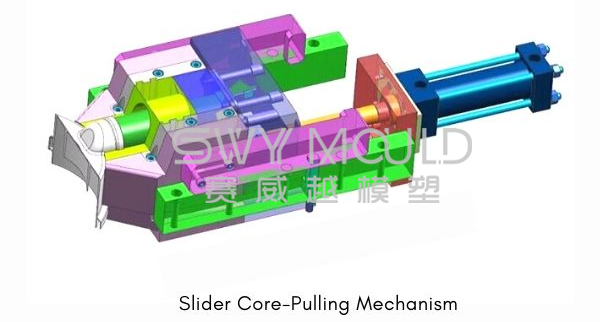

In the design of injection molds, a slider system is often used to the slider, this system is called the slide core-pulling system.

The slider core-pulling system is often used in the following two aspects:

1. Handling core pulling system with large packing force.

2. The core pulling system has an undercut, which needs to completed by second core-pulling.

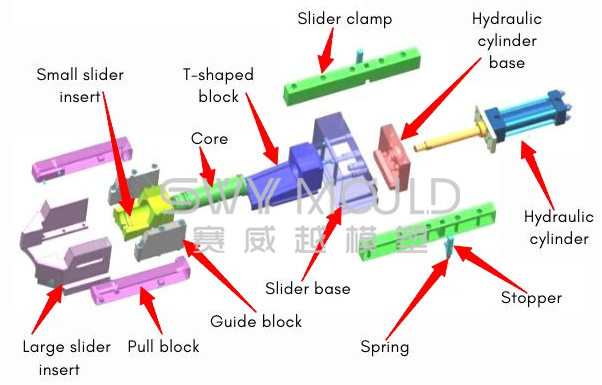

The common methods of design the slider core-pulling system

1. Spring delay

2. Delay stop (wedge to make a straight delay)

3. Mechanical stopper

4. Use the oil cylinder as a stopper

Classic slider core-pulling system

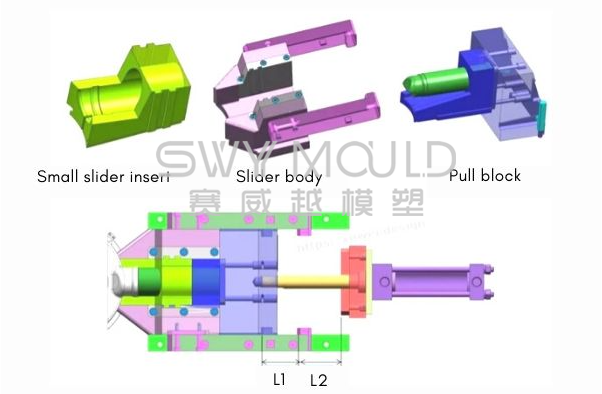

The figure below is a group of delayed core-pulling structures with mechanical stops, which are very practical.

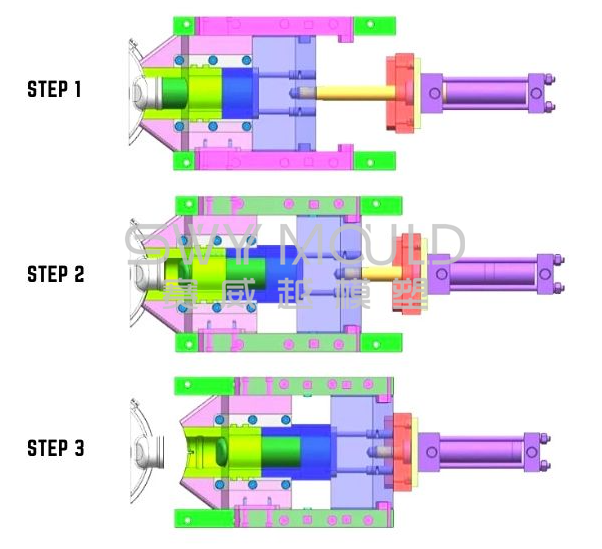

The structural principle of the core-pulling system

After opening the mold, the main body of the pull block moves backward under the driving of the oil cylinder. The small slider insert retracts downwards. Draw out the buckle on the product slot. At the same time, the slider body remains stationary under the action of the stop.

When the main body of the block travels a distance of L1. The small slider inserts have all come off the undercuts of the product. The first core pulling is completed. At the same time, the stopper moves backward. The pull block pulls the slider body. The second core draw begins. The oil cylinder continues to drive, and the sliding position moves L2 distance as a whole, completely detaching from the product.

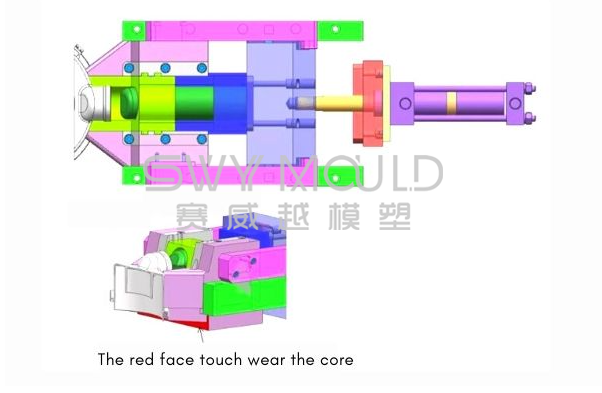

How to reset the core pulling system?

When clamping the mold, the block body first pushes the slider body to reset. When a large slider insert (red face) wears the core, the slider body is completely reset. The block body continues to move, pushing the small slider insert to reset. At the same time, the stopper also starts to reset until the mold clamping is completed.

Note: The slider body must be reset first. The small slider insert can be reset.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Cup Molding With Pattern Suppliers