USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Raw material: PP

Mold steel: P20

Mold base: 50C

Mold runner: hot runner

Ejection way: stripper

Guarantee mold life: 500,000 shots

Delivery date: 65 working days

Total two molds for this plastic kitchen recyclable bin product, one mold for the plastic kitchen recyclable bin body, one mold for the bin lid. SWY MOULD has made many bin molds, such as 1L, 5L, 10L, 15L, 20L, 25L, 40L, 50L, 60L, 120L, and so on.

For this mold, SWY uses an oil cylinder to move the pins for holes. Balance wall thickness with good mold tooling. During bin product design and mold design, we will consider the material shrinkage, raw material melt flow index, etc to choose the best injection gate size and position of bin molds. We will choose the best suitable solution for your bin molds according to your requirement, like mold runner, mold steel, mold ejection way, etc. Normally for bin mold etc household molds, mostly use P20 steel for mold core and cavity, it has 500000 shots guarantee mold life, suit for household molds.

For big bin molds, you can use a robot to pick up products out of the injection molding machine, it will be safe for production, and we will design molds to fit with your injection molding machine. After product design and mold design are confirmed, we will start purchasing mold steel and start mold tooling. We will use precision tooling equipment to process the bin mold, to ensure the wall thickness balance. We can finish mold tooling within 40 working days so that we can ship molds to you and you can start production in a short time. If you are interested in plastic kitchen recyclable bin molds, welcome your inquiry.

Main operation steps for plastic injection mold of kitchen recyclable bin

1. Receiving information from customers(concept,sample,physical model,2D or 3D data)

2. Transforming the information into a 3D data model by means of the CAD system

3. Purchase the material

4. CNC Milling and EDM manufacturing

5. Mold-Trial and a few samples produced

6. Delive the sample and get customers' opinion

7. Mold's final treatment

8. Deliver Molds and provide customer services

Factors need to be concerned in mold processing and manufacturing

1. The machining accuracy should be very well guaranteed

From the aspect of mold processing and manufacturing, it can be understood that molds are a very basic product for the production of any other commodity. It is precisely because of this that in the actual processing process, the precision treatment should always be placed in a very important position. In particular, it involves many molds that are very complicated in shape. It should be better to grasp the accuracy because only the accuracy of the mold can be guaranteed to make the next production successful, otherwise, the actual product produced in the next step Will cause waste of materials, which should be placed in a very important position in the mold production process.

2. Meet the conditions of repetitive production

In the actual production process, it is very normal that the mold is damaged and cannot be used. At this time, since the manufacturer has not made any changes in the product, it is very necessary whether the mold processing and manufacturing can meet the repeated production. As a manufacturer In terms of it, the previous production data should be kept very well. When repeated production is required, this need can be met. Only in this way can we provide more convenience for each part of the overall production, and can have a more ideal production effect.

3. Profiling processing technology should be improved

Although many mold productions have very strict requirements on various data, some of the productions do not have drawings and data and are only processed according to the shape of the specific product. This is indeed very difficult in terms of difficulty, but as As far as the actual manufacturer is concerned, the production technology that can meet this aspect has also become a very important part. Therefore, as a mold processing and manufacturing manufacturer, it is very important to be able to improve the technology better.

4. Excellent in mold materials

From the perspective of specific mold production, we can realize that a more serious grasp of materials has become a very important thing at present. The hardness of the material should meet the needs of the production. Only after the material can meet the relevant needs, each part of the overall production can be better understood. The final product is only in terms of quality and other parts. Can have a high guarantee, the content of this part should be better considered with a more serious attitude.

In this way, the various parts of mold processing and manufacturing can be better grasped, and it is hoped that every mold manufacturer can better understand these related content so that every aspect of mold production can be better protected. We can pay attention to all aspects of a specific production. As a manufacturer, only with continuous improvement in technology and better guarantees in terms of production materials can the overall production be truly smooth.

Mold steel & spare parts supplier in SWY

We have a qualified supplier system. From plastic material supplier to the steel material supplier, from mold component supplier to the hot runner supplier. All of the suppliers win well reputation in their industry.

Some of our customers will appoint suppliers that are well known all over the world like DME, Hasco, YUDO, Mastip, etc. The reason why they choose such kind of supplier is not only because of their good quality but also because they have distributors all over the world. Which they can easily ask for help if any of the components break. Meanwhile, such kinds of suppliers always ask for a high price.

Some other suppliers although they have no subsidiary abroad, they provide good quality inside the domestic market. It's no different for them whether it's a well-known brand or not, but should be of good quality at a competitive price.

The principle for us to choose suppliers in two factors, one is good quality, the other is competitive price.

Injection molding speed in the plastic molding process

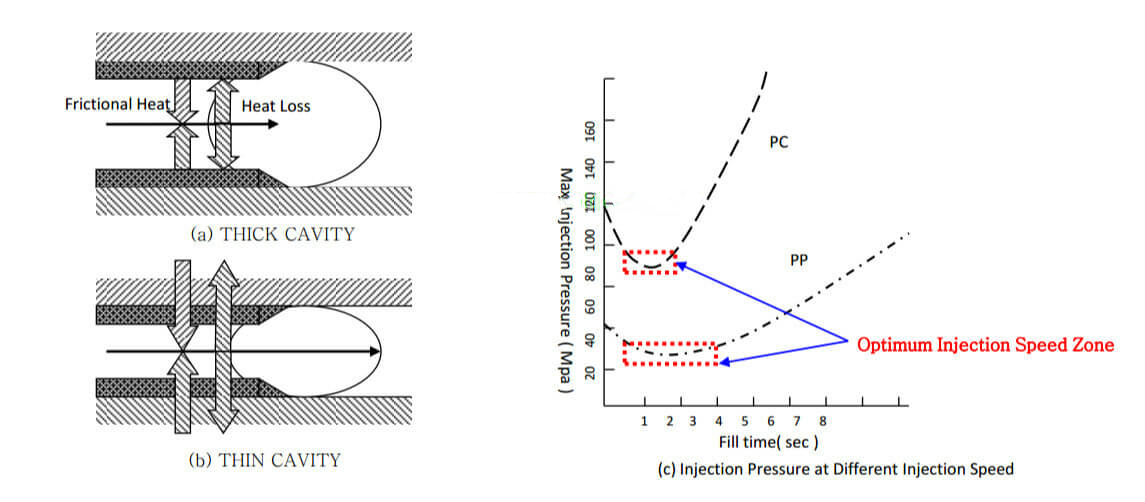

The injection speed relative to injection pressure shows a U-curve. If the injection speed is too low, heat loss will be greater than heat generation, causing flow temperature to drop, viscosity to increase and the solidification layer to thicken. So, resistance to flow, as well as injection pressure will rise.

On the other hand, when the injection molding speed is high, flow temperature will rise, the viscosity will decrease and the solidification layer will be thinner. However, the friction between the solidification layer and the flow layer will see a considerable increase, thus causing the injection pressure to rise. Injection pressure will be minimized when the flow speed is constant in the cavity.

Optimum injection speed

The optimum injection speed allows us to maintain minimum injection pressure under given conditions. Injection speed should vary with cavity thickness. Compared with the thick ones, the thin ones possess a smaller effective flow cross-section. As a result, we need to raise injection speed, improve overall deformation rate and increase frictional deforming force, so as to stabilize flow temperature and minimize injection pressure.

Injection speed also varies greatly with the heat capacity, thermal conductivity, and viscosity of resin materials. For materials (PC, PMMA) whose viscosity changes dramatically with temperature, the U-curve is smaller. For materials (PP, ABS) without this feature, the U-curve is much larger. Therefore, some materials are sensitive to injection speed, while some others are not.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Injection Mold Of Kitchen Recyclable Bin Suppliers