USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

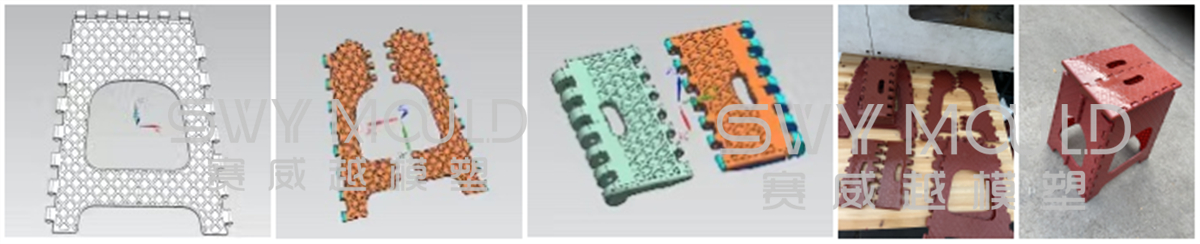

Part weight: 980g

Part size: 270*230*460mm

Needed mold quantity: 3 molds

Steel material: 718H

Mold base: 50#

Cooling cycle: water cooling

Delivery time: product & mold design: 7 days

cut steel: 3 days

mold machining: 25 days

mold assembly: 6 days

mold test and send samples: 3 days

The folding stool, a lightweight, stackable seat, is easy to move and saves space. The seat panel and the back panel are generally integrally molded with the original PP plastic in the mold; generally the bottom of the chair frame, that is, the position in contact with the ground, will be added with a footpad to prevent slipping and prevent the floor from being scratched. Use occasions: all kinds of training institutions, schools at all levels, public places, hospitals, restaurants, hotels, companies, families, and other places.

Welcome to contact our SWY MOULD to customize your plastic folding stool mold.

The reason to choose our SWY MOULD

1. Experienced & stable core team member

All key staff like the engineer, the toolmaker manager, the project manager, the injection manager all have over 10~30 years experience in the mold industry, and they had been working with us for more than 8 years and some have become partners of SWY.

2. Big size injection machine up to 3000T

Our injection machines ranging from 90 tons to 3000tons, so can make plastic molding part size up to at least 2m, and mold weight up to 20-30tons .and also equipped with a robot arm for efficient production.

3. CNC machining accuracy to 2μm

Well equipped the CNC to control the accuracy, so that can be better ensure the quality of the mold and bring customers more convenience and more advantage to compete.

4. CMM measuring accuracy to 0.01mm

To control quality and accuracy is our duty to act without hesitance. To correctly follow the ISO quality procedure, equipped with precision testing machines and attention to the quality of every SWY people is our commitment to customers.

5. One-stop service

Our over 16 years of experience in the mold industry, allows us to provide one-stop service including design optimization, material selection, prototyping mold, mold design, injection mold building, plastic injection molding, logo printing, pad printing, plating, ultrasonic welding, related parts sourcing, assembly, packing as well as transportation arrangement. SWY will only gain a reasonable margin on in-house products and processes, pure cost will be charged on outsourced parts.

Plastic outdoor folding stool injection mold maintenance

1. After the mold is used for a long time, the cutting edge must be sharpened. After grinding, the cutting edge surface must be demagnetized, and it cannot be magnetic, otherwise, it will easily block the material. The mold manufacturer shall make detailed records, count its use, care(lubrication, cleaning, rust prevention), and damage, and thereby find out which parts and components have been damaged and the degree of wear and tear to provide information for discovering and solving problems. And the molding process parameters of the mold and the materials used in the product shorten the test time of the mold and improve the production efficiency. The various properties of the mold should be tested under the normal operation of the injection molding machine and the mold, and the size of the final molded plastic parts should be measured. Through this information, the existing state of the mold can be determined, and the cavity, core, cooling system, and the damage of the parting surface, etc., according to the information provided by the plastic parts, can determine the damage state of the mold and maintenance measures.

2. Springs and other plastic parts are most vulnerable and deformation occurs. The method adopted is to replace. In the process of replacement, we must pay attention to the specifications and models of the spring. The specifications and models of the spring are confirmed by the color, outer diameter, and length. Only when all three items are the same can be replaced. The spring is preferable of quality of the inlet.

3. During the use of the mold, the punch is prone to breakage, bending, and smashing, and the punching sleeve is generally smashed. Damage to the punch and sleeve is generally replaced with parts of the same specification. The parameters of the punch mainly include the working part size, the mounting part size, and the length size.

4. Fasten the parts and check whether the fastening parts are loose or damaged. The method is to find the parts with the same specification for replacement.

5. Pressing parts such as pressure plate, superior glue, etc., unloading parts such as stripping plate, pneumatic top material, etc. During maintenance, check the accessories of each part and whether there is any damage, repair the damaged part, check the pneumatic top material for air leakage, and take measures for the specific situation. Replace if the air tube is damaged. It is necessary to carry out key tracking and inspection on several important parts of the mold: the function of the ejection of the plastic parts. If any part is stuck due to damage, it will lead to production stoppage, it will lead to production stoppage, so it should be kept frequently. Lubricate the thimble and guidepost of the mold(use the most suitable lubricant), and regularly check the thimble, guidepost, etc., for deformation and surface damage. Once found, replace it in time; after completing a production cycle, work on the mold surface., sports, guide parts coated with professional anti-rust oil, especially the protection of the plastic strength of the bearing parts with gears, rack and die, and the spring mold to ensure that it is always in the best working condition; as the production time continues the cooling channel is easy to deposit scale, rust, sludge, and algae so that the cooling passage section becomes smaller, the cooling passage becomes narrower, the heat exchange rate between the coolant and the mold is greatly reduced, and the production cost of the enterprise is increased, so the flow path is cleaned. Attention should be paid to it; for hot runner molds, the maintenance of the heating and control system is beneficial to prevent production failures, so it is especially important.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Outdoor Folding Stool Injection Mold Suppliers