USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

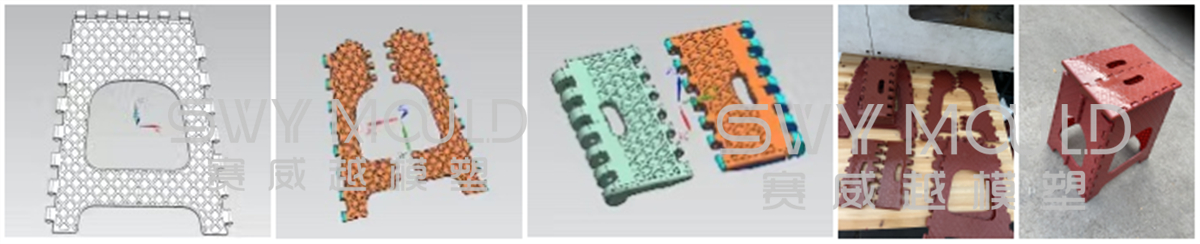

Part weight: 980g

Part size: 270*230*460mm

Needed mould quantity: 3 molds

Steel material: 718H

Mould base: 50#

Cooling cycle: water cooling

Delivery time: product & mould design: 7 days

cut steel: 3 days

mould machining: 25 days

mold assembly: 6 days

mold test and send samples: 3 days

The folding stool, a lightweight, stackable seat, is easy to move and saves space. The seat panel and the back panel are generally integrally molded with the original PP plastic in the mold; generally the bottom of the chair frame, that is, the position in contact with the ground, will be added with a footpad to prevent slipping and prevent the floor from being scratched. Use occasions: all kinds of training institutions, schools at all levels, public places, hospitals, restaurants, hotels, companies, families, and other places.

Welcome to contact our SWY MOULD to customize your plastic folding stool mould.

For designing the folding stool mold, we should pay attention to some points

1. Pay attention to the degree of firmness: look at the overall quality of the frame, and use both hands to shake the product back and forth, shake it and shake it. Need to have a design to prevent the hand, the product can not be sharp edges such as easy to cut the hand.

2. Evaluate the material, hardness, and load-bearing capacity of the stool.

3. Evaluate the stool supporting or use occasions, choose the right stool.

4. The easy way for folding and take away.

5. Lightweight and can be stackable.

For testing the folding stool mold, the following items should be checked

1. Whether feeding stroke is too long or insufficient.

2. Whether the pressure is too high or too low.

3. Whether filling speed is too fast or too slow.

4. Whether the machining cycle is too long or too short.

To prevent short shots, fractures, deformation, burrs, and even damage to the mold.

If the processing cycle is too short, the ejector pin will push through the finished product or peel ring to crush the finished product. This kind of situation may make you spend two or three hours taking out the finished product.

If the processing cycle is too long, thin parts of the mould core may be broken due to the shrinkage of rubber.

Of course, you can't anticipate all problems that may occur during the mold trial process, but taking full consideration of timely measures in advance will help you avoid serious and expensive losses.

Mould manufacturing & quality control system

SWY Mould provides more injection molds parts design and manufacturing services. All of the projects we will put them from DFM to PFM working flow to ensure products quality, from moulds design, mould flow analysis, per-mould machining review a series of testing reports to make sure mould production running smoothly. We are proud of our mould producing flowing, product quality guarantee, delivery on time and we have a professional engineer team to support your projects, make it so easy, make you so comfortable.

After-sales service from SWY MOULD

1. Free replacement: standard injection mould 1-year quality free guarantee, free replacement by new accessories if non-external reasons

2. Mould life: moulds from 500k to 5 million mold life; molding meets fast market mould guarantee time

3. Timely communication: respond to your questions in time within 24 hours and help you develop solutions

4. Information supplying: provide drawings and changed data used in the mould manufacturing process

5. Maintenance: provide mould maintenance plan, maintain your mould comprehensively

6. Regular return visit: visit your mould usage regularly, give you professional advice and get valuable customer feedback

7. Regular customer service: build your data into our customer database to make you become our regular customers for more preference and discount

8. Tailor special support: we will supply special support for repair and warranty time All SWY moulds are lifetime service and drawing support

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mould Of Plastic Folding Stool Legs Suppliers