USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

This mold is made with two parts, one the basket long handle, and another one is the plug for locking the small handle.

Part material: PP

Mold steel: P20H

Mold cavity: 2+6

Runner system: cold runner

Mold size: 770*450*340mm

Mold weight: 685KG

The benefit habits for operating injection molding machine

1. Before the machine starts

* Check to see whether there is any water or oil inside the electrical control box. Don’t turn it on if the machine is affected by moisture. It can only be turned on after the parts are dried by the service staff.

* Check whether the voltage meets the requirements, which is usually kept within the range of ±15%.

* Check the effectiveness of the EMERGENCY STOP button, as well as the switch between the front and back safety doors. Verify whether the rotating direction of the electric motor and the oil pump are consistent.

* Check to see whether each cooling channel is smooth and free from any blockage, and let coolant into the oil cooler and the water jacket at the machine barrel end.

* Check to see if all joints are lubricated, and add lubricant/grease when necessary.

* Turn on the electric heat control system to heat each section of the machine barrel. Hold the temperature for a while after each section is heated up to the required temperature, so as to obtain a relatively stable machine temperature. The temperature holding time varies with different equipment and plastic materials.

* Feed sufficient plastic materials into the hopper. According to different plastic injection molding requirements, some materials need to be dried beforehand.

* Keep the machine barrel covered with a heat shield, so as to save power, and at the same time increase the service life of the electric heater and the contactor.

2. During the operation process

* Do not ignore the importance of the safety doors for convenience.

* Always pay attention to the temperature of the hydraulic oil, to keep it within the allowed range. The ideal working temperature of the hydraulic oil should be kept between 45 and 50℃; usually, the proper temperature ranges from 35 to 60℃.

* Don't forget to adjust each travel distance limit switch, to avoid collision during machine operation.

3. After the operation

* Before turn the machine off, thoroughly clean the machine barrel, so as to prevent the residue materials from oxidation or decomposition caused by long-time heating.

* Open the mold to keep the elbow-bar mechanism locked.

* The workshop needs to hoist all the equipment. Carefully handle the heavy mold parts and components during the assembly/disassembly process, to ensure production safety.

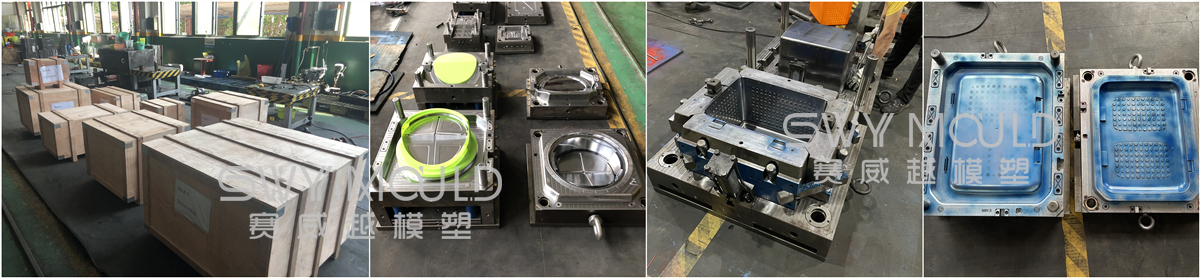

Rectangular basket plastic handle injection molding shipment details

1. Quality inspection of plastic mold installation

A complete inspection of plastic mold to ensure the continuity of mold structure and the standard of parts. The project manager and quality inspection personnel shall inspect the plastic mold according to the company's standard, so as to ensure the quality of the products. Once the problem is found, it can be corrected immediately, and effectively prevent the occurrence of errors. In addition, we continuously test the cooling system, hydraulic oil duct system, and hot runner system of plastic mold.

2. Checking before mold delivery

* After confirming the sample of the customer, our manager will inform our team leader to check the mold. Including the 3d mold design, customer's requirements, and mold trial problem.

* If our customer needs the water channel drawings and oil channel drawings, we will print them for you, of course, we could provide mold water transport pictures.

* After all the detailed checking no question, then we will inform our team leader to packing the mold.

3. Mold specification

* Team leader will fill in the instruction

* Packing all the mold accessories into a wooden case

* Prepare mold trial report, mold using instruction, mold temperature control box instruction, and quality certification to customer.

4. Mold Packing

* Cleaning the cavity and core, no iron filings

* Spraying the antirust paint inside and outside

* Wrapped with the plastic film

* Putting into a wooden case or wooden pallet

Why choosing our SWY MOULD?

Saiweiyue Mould located in Huangyan of China were to have the famous name of "China Mould Town", we are specialized in plastic injection molds, our main products are auto part molds, home appliance molds, household product molds, child product molds, and industrial product molds. Most of our products are exported to America, Argentina, Brazil, Ecuador, Egypt, India, Iran, Macedonia, Mexico, Pakistan, Peru, Singapore, Sri Lanka, Spain, Sudan, etc. Our mission is "providing customer best solution for mold making and injection", and our desirability is to "have high competitive power, become a specialized and famous mold company". We based on professional technical talents, sophisticated equipment, perfect management system, then we can provide customer best service and create value for the customer.

SWY Mould can offer one-stop R&D services from engineering design, mold machining, mold polishing, mold assembly, to custom injection molding, as well as 3D printing and assembly, etc. Design for manufacturability and efficient production is our primary objective. The mold drawings can be finished within 2-4 days then send to the customer for checking before start tooling. We are able to meet our customers' shortened lead time. All the necessary technical drawings will be sent to customers for future mold maintenance references.

Our high-speed milling machine, EDM, WEDM, and CMM optimize our tooling process and improve the accuracy and efficiency of our mold to ensure customers can get quality products. Our expertise in tooling leads to better results in molding. We have enough experience working with materials such as LDPE, HDPE, PP, ABS, PC, PS, PVC, PA, PMMA, POM, etc.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Rectangular Basket Plastic Handle Injection Molding Suppliers