USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

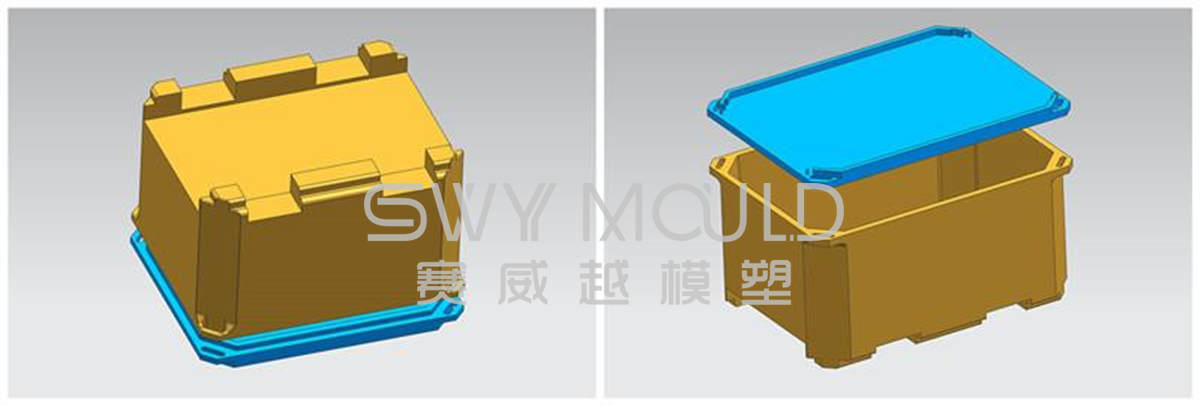

Part size: 47.5"*42"*34"

Part capacity: 1200lb

Plastic resin: HDPE

Mould steel: 718H

Mold base: C50

Injection system: hot runner

Features of plastic insulated fish tote

Made of high-density polyethylene, non-toxic, odorless, and hygienic material preventing the formation of bacteria. The stackable lids are designed to drain off any residual water, make possible the stacking of totes, and preserve the freshness and taste of the fish. Easily cleaned simply by hosing or steaming. Highly resistant to chemical corrosion and sea salt. Lightweight but sturdy and safe, they can be handled securely because of their reinforced handles.

What do you need to offer after ordering the plastic insulated fish totes mold?

1. Your idea about the plastic insulated fish totes or ready designs or samples

2. The budget for starting the mold production

3. The production capacity (your machine tonnage and machine quantity)

4. Any special demand:

* purchasing other tools for your mold production

* mold mass production training

* mold and product requirement

Excellent tooling team and effective control policy

Our technical team is more than seven years in the industry, with rich experience, has developed a lot of successful mold products. Analyze part design for all new projects and apply design experience to the production to maximize tooling capacity, reduce secondary operations, shorten assembly time and simplify positioning. At every stage, we try our best to make the perfect combination of materials, manpower, machine efficiency, cost-effectiveness, and production.

In many difficult mold projects, we are honored to cooperate with our customers, through our joint efforts to solve various problems in the project. We introduce innovative solutions to ensure successful and timely product launches. In the process of mold design and manufacturing, we always require our salesmen and technical personnel to keep timely communication with customers on mold-related issues, and obtain customers' recognition and support, only in this way can the interests of customers be maintained to the greatest extent.

Efficient machinery and equipment

Numerical control (computerized digital control) machining is an automated process in which computer files are processed by machines to create highly complex plastic or metal objects.

Whether it's one or 100, our processes are designed to be efficient. High-quality raw materials, high-speed machining centers, and state-of-the-art machines allow us to produce your parts in a short time, simple or complex, and we can deliver them to you in days instead of weeks.

We have high-speed CNC machining ready to deliver custom CNC parts you need to keep your project moving forward.

When only one or a few parts are needed, we will work with you to ensure that you have CNC machined parts and you need them when you need them. After all, you have customers waiting for you, and you don't want to disappoint them, and we won't disappoint you.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mould Of Plastic Insulated Fish Totes Suppliers