USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Beer case weight: 1.3kg

Beer case bottle No. : 15 bottles

Beer case dimension: 410*310*240mm

Beer case mould dimension: 850*750*655mm

Hot runner for this Beer case mould: 6 tips hot runner with Anole Hot Runner system

Injection molding machine: 650T servo motor molding machine

Beer case mould steel: DIN1.2738 with Be Cube with mold guaranteed life 3 million shots

Beer case mould spare parts: OEM standard

Cycle time: from28s to 35s, it depends on the hot runner and injection machine

Ejection way: Hydraulic Cylinder with stripper plate or hook system with stripper

For the bottle case mould, SWY MOULD could make beer case mould, Cola case mould and other case moulds according to customer requirement and design for 12bottles, 20bottles, 24bottles or another customized type. We have rich experience for bottle case production line service, together with plastic bottle case mould, we can provide crate injection mass moulding.

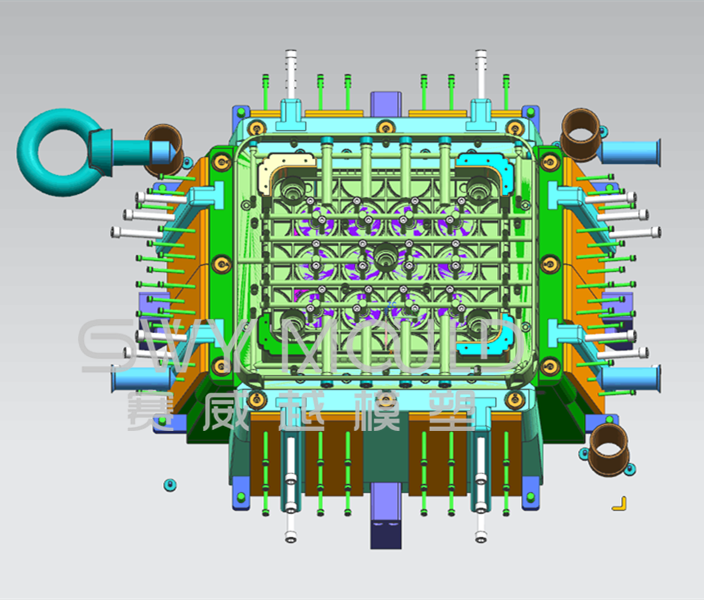

The design of the beer case mould

For a beer case mould, the mould design structure is very important to get a lasting running mould with a fast cycle time. According to the top mouth design, we choose a suitable mould structure with lifter support for demolding, and for the core insert, we use Cu-Be material for better cooling. Precision tooling is very important for the distance of each case, our company has all the precision tooling machines in the workshop, such as high precision milling machine, wire cutting and EDM tooling.

This mould is designed with a 4 side angle lift and 4 side handle with a hollow on the 4 sidewalls. For this kind of beer case mould, we can make the mould 25s injecting cycle time with automatic dropping. During design, we pay attention to the best cooling system to realize a perfect cooling effect. And suitable case mould structure, hydraulic stripper structure or puller rod ejection, to fast cycle time and increase mass production quantity. Secondly, reduced product weight is taken into consideration when we design a glass bottle crate to get lighter-weight bottle crates. Our customer decreases production cost and increases their competitive ability.

The selection of an injection moulding machine

When we choose a suitable machine size for the beer case mould, the main tip we have to consider is the machine open stroke, we must check carefully that the moulding case part could get out smoothly when mould opening, so the machine size for common beer case is above 600ton.

The way of selecting a suitable injection moulding machine

1. Determine the injection weight of IMM.

Injection weight is an important parameter for IMM. It is the most useful and key parameter for choosing a machine. It is expressed by gram or ounce, although this parameter is simple and easy to understand, it is also easily misunderstood. The reason is very simple. When the plastic material is sure, the weight of the plastic parts can be determined. Therefore, it is easy for them to use the injection weight to choose the machine. In fact, the definition of injection weight refers to the maximum plastic injection weight that can be reached by the injection device when the screw makes a maximum injection stroke under the condition of empty injection (not inject to mould); this parameter reflects some extent the processing capability of the injection moulding machine; it can be measured and can also be from the theoretical calculation(the theoretical value and the measured value may have a certain degree of difference). The material used for the test is usually a normal PS with a density of 1.05.

Steps to determine injection weight:

* First calculate the weight of the product: W = product weight + gate system weight, in which: W the weight required for injection.

* When the injection molding product is polystyrene (PS), the injection molding machine should have an injection volume of Wps; Wps = (1.3 ~ 1.1) × W (product weight + total weight of the gate system) when there is a high requirement for the product, the coefficient in the above equation should take a large value, and vice versa, it can take a small value.

* When the product is other plastic (named X plastic) to imitate the method, first calculate the theoretical injection volume of the plastic should have the Wx; Wx = (1.3 ~ 1.1) × (product weight + gate system total Weight); then based on the density of the plastic (X) is converted into the actual weight of the PS material Wps, the conversion formula is: Wps=Wx × 1.05/Vx

2. Calculate injection molding machine clamping force

There are two important factors for calculating the clamping force: one is the projected area, and the second is the cavity pressure.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Beer Case Injection Mould Suppliers