USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Product material: ABS/PC + TPU

Cavity/core steel: S136 with heat treatment

Slider steel: S136 with heat treatment

Cavity: decided by your machine tonnage

Cavity surface finish: polish

Core surface finish: texture

Type of gating: pinpoint gate/submarine gate

T1 day: 45-55 days

HS Code: 8480719090

Plastic TV set, there is a high requirement on the part surface, no flash, no ejection mark, and no drag mark. Also, there is a certain demand for part strength. So in mold design, should concern the welding line, the ejection system, the size matching, etc. For raw material, should concern the material certain performance, shrinkage rate, fluidity, etc.

Here SWY MOULD would like to talk about one TV front frame mold we made before:

1. Structure analysis

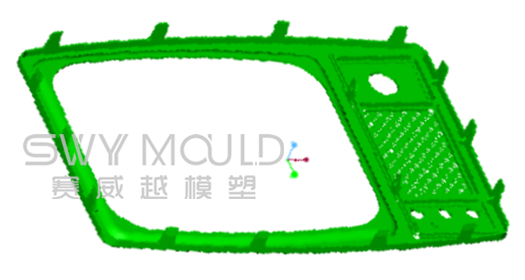

The shape of the frame as following, the size is 405*264*31mm.

2. Wall thickness analysis

According to the analysis of Pro/E, the wall thickness of this part is uniform, the average thickness is 2mm.

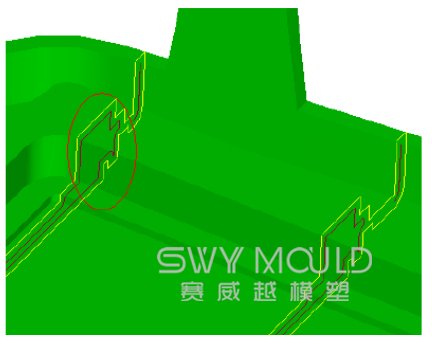

The wall thickness of the red zone is thick, when molding there will be shrinkage, after discussing with our customers this point, they agreed to decrease the wall thickness to achieve good performance.

3. Molding analysis

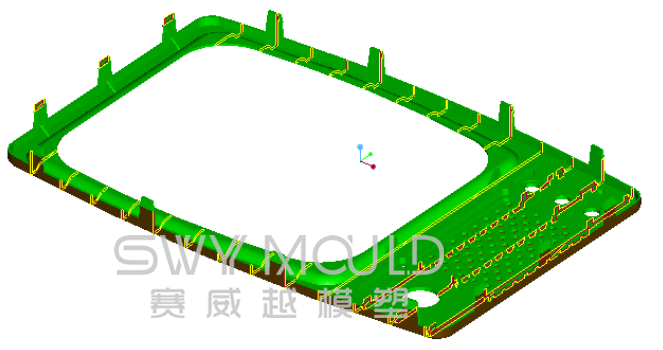

As the size of the front frame is large, commonly adopt one cavity for one mold, the arrangement of the cavity is simple.

Due to there is a high requirement on the part surface, so putting the outer side on the female mold, and the inner side on the male mold, also it's convenient for mold ejecting and demolding.

4. Raw material selection

As for TV set part material, there is a high requirement for the material of anti-corrosion, abrasion resistance, good mechanical properties, and stable performance. According to all points, the ABS material is a good choice.

Performance of ABS material:

*Density: 1.02-1.16kg*dm³

*Shrinkage rate: 0.4-0.7S

*Melting point: 130-160°

*Distortion temperature: 90-108 (0.46 Mpa)

*Tensile yield strength: 50 Mpa

*Modulus of elasticity for tension 1.8e03 Mpa

*Flexure strength: 80 Mpa

*Hardness(HB): 9.7

*Volume resistivity: 6.9e16

5. Joint face analysis

The principles for design the joint face:

*Easy for demolding, the plastic part tries to stay in the male mold, and easy for ejection.

*Ensure not damage the part surface

*Ensure the part size precision

*Good for air venting

*Convenient for mold machining

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM TV Set Plastic Molding Suppliers