USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Product Size: 500*290*220mm

Raw material: PS

Mould cavity: 1 or more cavity (according to your injection machine size)

Mould main material: DIN 1.2738

Hardness of steel: HRC32-50

Mould injection system: ANOLE valve gate

Mould ejection system: angle lift and ejecting block with round ejector pin

Mould cycle time: 24 Seconds

Delivery time: 60 working days

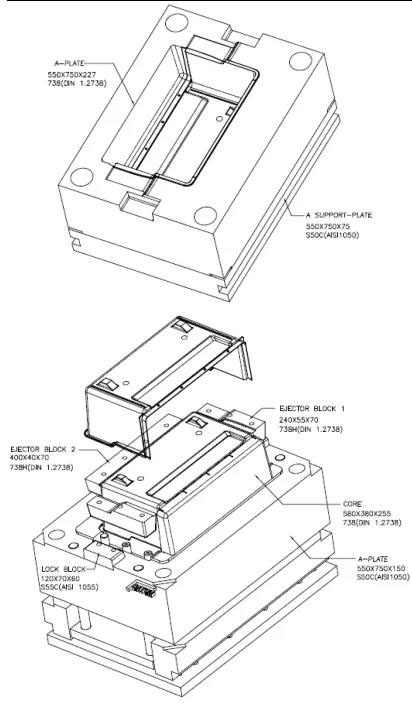

The design of the plastic refrigerator part mould

This product is designed for drawers of an Italian brand refrigerator. It can be seen from the picture that the plastic part is a box shape with one side open, the size of the plastic part is large, and the production batch of the plastic parts is also large. Mould is required to have good long-term service performance and mould life is 300,000 shots.

According to the size of the plastic part and specifications of the customer’s injection molding machine, the mold design cavity is layout as 1 cavity; the size of the plastic part is larger, and the molten plastic process is longer, so the gating system is designed as a hot runner mold. Gate position is on the bottom surface of the refrigerator drawer, and two-point gates are filled with material. The hot runner system adopts the DME brand.

Because it is a hot runner mould, the mould base is a non-standard mold base CI5575; two inclined positioning blocks 10 are designed on the long side of mould base to prevent lateral deviation caused by injection pressure. Two non-standard positioning blocks 3 are designed on both sides of top and bottom to facilitate accurate mold clamping. Mould is a large-scale mould, the cavity is left in its original form, and the cavity is directly processed on the A plate. At this time, the material of A plate needs to be made of die steel 1.2768.

In order to prevent plastic parts from deforming and shorten the injection cycle of refrigerator drawer mould, sufficient cooling water circuits are designed for front and rear moulds. Water transported by the front mould is straight-through water, which is evenly distributed around the cavity. Back mould is a pond. Adequate cooling system design can ensure that plastic parts are not deformed and injection molding can proceed normally.

The ejection of plastic parts depends on push block, push block, and ejector pin. The push block is pushed out with a push rod and guided by a guide bush. The pushrod is directly fixed on the thimble plate. The ejection mechanism is a European mold structure with strong tension and strong ejection. No spring is set on the return pin. Tap M24 at the corresponding position of K.O holes on the ejector plate, which is convenient for connecting the ejector rod of the injection molding machine. The thimble plate is designed with a travel switch to confirm the return.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Storage Box Mould For Refrigerator Suppliers