USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Raw material: PVC

Wall thickness: 2.5-3mm

Mould steel: S136

Mould base: C50

Mould cavity: 20

Structure: side core-pulling system

with the draft angle for demoulding

What is an RJ-45 plug?

Have you ever noticed the copper cable plugged into your computer? Or to put it specifically, the crystal connector in your computer? That’s what we called the RJ-45 connector. What is an RJ-45 connector? It’s a common component used to connect computers into Ethernet-based local area networks (LAN).

A: connector jacket

B: metal shell of the connector

C: wire holder of the connector

D: connector plug

E: ethernet cable jacket

F: shield layer of the ethernet cable

G: twisted pairs

The raw material of the RJ-45 plug

PVC is Polyvinyl Chloride. This is a plastic that has the following chemical formula: CH2=CHCl (see picture on the right).

Plastic covers a wide range of synthetic or semi-synthetic polymerization products (i.e. long-chain carbon-based "organic" molecules) which name refers to the fact that in their semi-liquid state they are malleable, or have the property of plasticity.

In common, PVC is used to produce plug, socket, switch, and other parts in industry.

1. Features of PVC raw material:

* Density: ρ=1.15-2.00g/cm³

* Shrinkage rate: s=0.2-0.6%

* Melt temperature: 185-205℃

* Tensile strength: 40-52Mpa

* Bending strength: 80Mpa

* Compression strength: 22-39Mpa

* Breakdown voltage: 15 KV/mm

2. Molding techniques of PVC

* Screw speed: 20-30 r*min

* Nozzle: temperature---150-170℃

form---straight-through type

* Barrel temperature: front section---170-190℃

middle section---165-180℃

rear section---160-170℃

* Mould temperature: 30-60℃

* Injection pressure: 80-130Mpa

* Holding pressure: 40-60Mpa

* Injection time: 2-5S

* Holding time: 15-40S

* Cooling time: 15-40S

* Cycle time: 40-90S

Analysis of the plastic RJ-45 plug shell injection mould

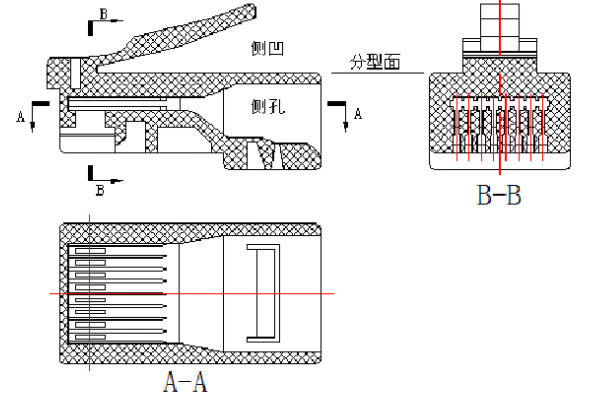

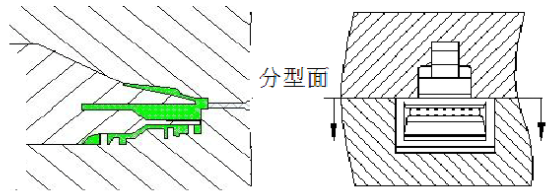

1. The structure analysis

The RJ-45 plug has a complex structure on outer shape and inner side, no metal insert and logo, there is concave in the side part, so need to use side core-pulling system.

2. The analysis of part size and precision

The size of the plastic part is decided by the material mobility. The factors which influence the part precision are as following:

* Fluctuate of material shrinkage

* Changement of molding techniques

* Mould structure

*Mould making tolerance and abrasion after using

3. The analysis of surface requirement

The requirements for the PJ-45 plug are there is no defect, no warpage, and has good gloosy. For the surface, it should be in good abrasive resistance.

4. The arrangement of the cavity part

As for the arrangement of the cavity, the most important is making the runner balance. The length, cross-section shape, and size from the sub-runner to the main runner are the same so that the material can flow into the cavity with equal speed and quantity.

5. The design of mould joint face

The principle of making a joint face on mould:

* Easy for demoulding

* Ensure the part precision and surface requirement

* Easy for mould machining

* Easy for mould venting

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic RJ-45 Plug Shell Injection Mould Suppliers