USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part size: 20.46*39.8mm

Part material: PC

Mold steel: H13

Mold base: C50

Mold cavity: 16

Gate system: pinpoint gate+sub runner

Injection system: 3-plate mould

Ejection system: ejector pin

Mold features: 4 sliders+4 lifters

Plastic injection mold design process

1. Questions from the designer

* How will the product use?

* Where will the product use?

* How important is product appearance?

* What method of assembly, packaging, stacking, nesting,… will use?

* Where does design choose gate local?

* How many gates, typical of gates used in this mold?

* How to choose a parting line for the product?

* Properties of injection machine

* How to choose the draft angle of the product?

* Tolerance of the product

2. Common design process in SWY

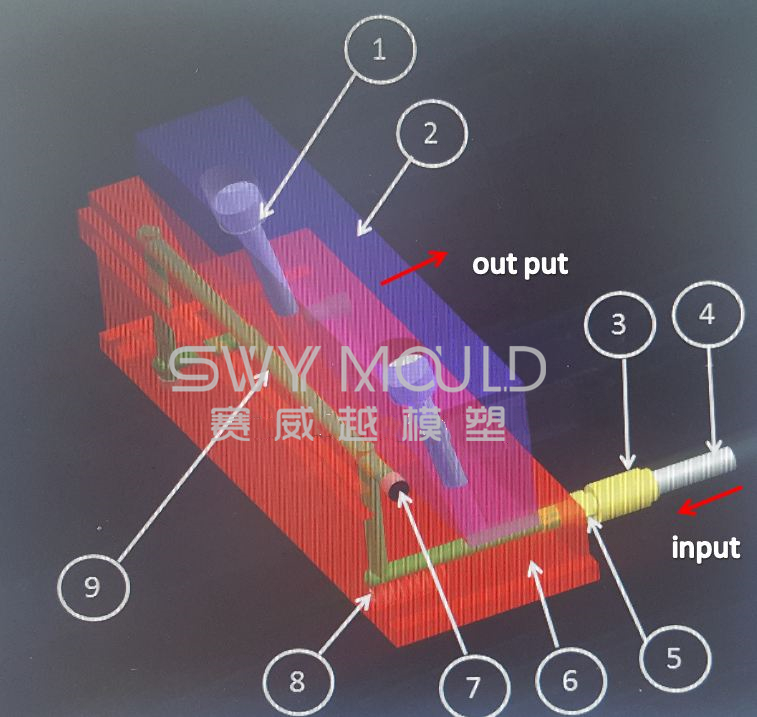

Slider cooling channel system in plastic mold

1. Angular pin (Gray color)

This pin has a draft angle from 10 deg ~25 deg. It will transfer vertical movement of cavity plate to horizontal movement of slide core. Angular pin usually fixes by cavity plate and slide locking block.

2. Locking block (Purpose color): locking block to make angular slider pin is shorter and increase the strength of angular pin.

3. Socket (Yellow color).

4. Flexible coolant hose (Gray color).

5. Plug (Yellow color.)

6. Slider insert core (Red color).

7. Pressure plug (Black color): it used to prevent cooling material out of the slider core.

8. Spring: when the angular pin and slide core separate, the spring force will push the slide core moving forward.

9. Cooling channel (Green color).

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Charger Head Housing Mold Suppliers