USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Housing material: ABS

Housing size: 360*270*170mm

Mould steel: 718

Mould base: DME

Injection system: hot runner

Surface requirement: high glossy

There are many parts to build a set of plastic coffee maker mould. When you inquiring from us, kindly provide us separate parts pictures with size, so SWY Mould can give you detailed quotation.

Most small home appliance moulds are plastic parts, so the production cycle of products depends on the production cycle of plastic moulds. In this paper, coffee maker mould, using more mature CAD/CAM software on market – mold flow analysis software Moldflow, analyzes filling, gate, cooling, and warpage of mould, and gain more valuable time for mould improvement design.

Plastic parts process of coffee maker mould analysis

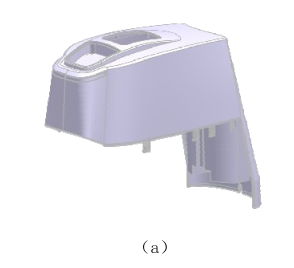

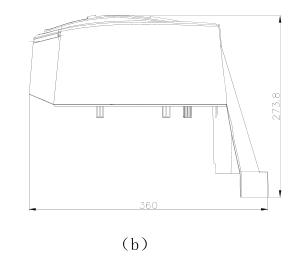

Figure 1(a) is a three-dimensional view of the coffee maker mould, and Figure 1(b) is a two-dimensional view. The size of the plastic part is larger 360×270×170mm.

Wall is thin, the structure is complicated, inside has an inverted buckle, slender cylinder (screw hole), upper and lower asymmetry, left and right asymmetry, etc., which bring many uncertain factors to filling pressure and other links. Inner and outer surfaces of plastic parts are not smooth, difficulty in manufacturing and forming mold is also increased to some extent. Plastic material uses ABS (acrylonitrile-butadiene-styrene copolymer), which has high melt viscosity, is sensitive to temperature and shear rate, and requires higher mold manufacturing. Therefore, in order to improve the success rate of the test mode, it is particularly important to perform mold flow analysis on the design process of the plastic parts before mold processing.

Figure 1 coffee machine mould

Moldflow analysis of plastic coffee maker housing mould

1. Pre-processing of finite element model

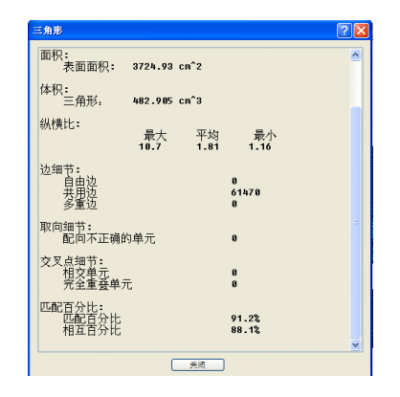

Use UG software to complete 3D model of the plastic part, export it to x_t format, and then import this file through AMDL which comes with CAD DOCTOR, do some simplification and repair processing in CAD DOCTOR software, such as removing duplicate faces, free edges, short lines, broken Surface, etc., to simplify small structures that do not affect analysis, such as steps within 1mm, rounded corners below 1mm. After mold manufacturing, import it into Moldflow for meshing. Double-layer mesh used. The maximum aspect ratio of the triangle is required to be controlled below 13, the average aspect ratio is controlled below 10, free edge, multiple edges are 0, the misaligned face must be 0, intersecting unit and full overlap unit are 0, the matching percentage is controlled at around 90%, and model fully meets required requirements.

Figure 2 shows grid statistics.

2. Analysis of gate location

Choice of gate location plays a crucial role in mould design. It directly affects the shape and speed of flow of molten plastic front, which will affect the warpage of plastic parts and have a very obvious influence on weld lines and also plays a decisive role in holding pressure. In particular, the multi-gate injection should consider the position of the gate, control the flow model of melt filling, and avoid over-pressure. This mold uses two gates to feed glue. Due to the particularity of plastic parts, glue not balanced. Figure 3 is a diagram of the end filling path, from which it can be seen that filling time at each of the most distal ends of the model is inconsistent with the coffee maker mould.

Figure 3 Filling path graph

3. Analysis of the runner system

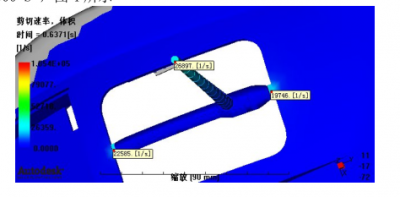

Mould is one out of one, and the runner system is relatively simple. However, it is also necessary to ensure that plastic parts can be filled smoothly, flow rate and gate rate are guaranteed to be below the maximum shear rate of material. In order to save costs, the flow size design is as small as possible. Therefore the main channel has a hole diameter of 4 mm and a taper angle of 1 °. Shunt channel made large (12 mm) and small (8 mm). In order to reduce filling and holding pressure, shear rate reduced, gate width is 6 mm, and thickness is 2. 5 mm. The measured shear rate is up to 26897 S-1, which meets the maximum shear rate of 50000 S-1, as shown in Figure 4.

Figure 4 Shear rate

4. Filling analysis

Filling analysis is very important in the entire simulation analysis. It simulates filling the entire plastic part. It can find many problems before the test and can be corrected in time.

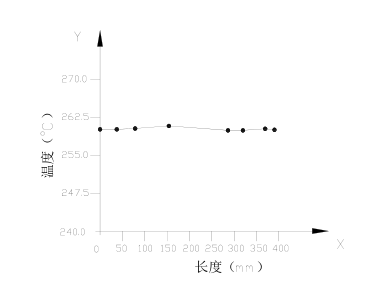

Figure 5 is a flow front temperature map. It can be seen from the figure that it is basically consistent, which indicates that the filling process is not obstructed and the process is smooth by Moldflow.

Figure 5 Front temperature path graph

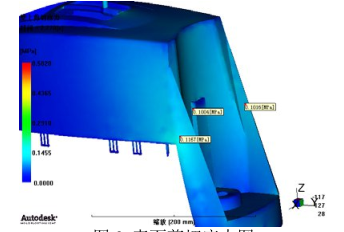

Figure 6 is a surface shear stress diagram, the maximum value is 0. 1167MPa, yield limit of the material is 0. 3MPa, according to first strength theory, it is known that condition satisfied and safe.

Figure 6 Surface shear stress

5. Packing pressure – warping analysis

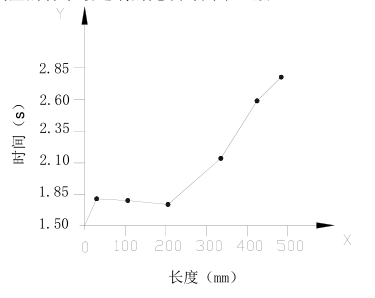

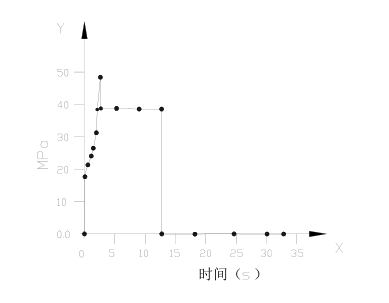

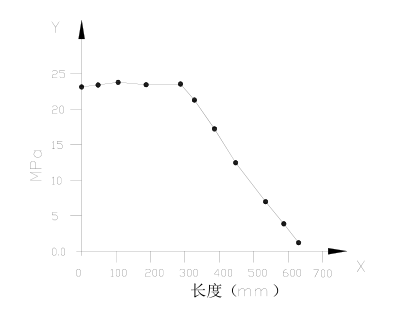

Figure 7 shows the time-pressure diagram at the injection site, showing pressure at the injection site from the end of the hold. It found that the peak value of injection pressure higher than the pressure value at the time of injection/pressure holding switching. This indicates that there a partial loss of pressure during the mould manufacturing process, it found that one end of filling squeezed, and a part of pressure consumed.

Figure 7 Time—Pressure graph

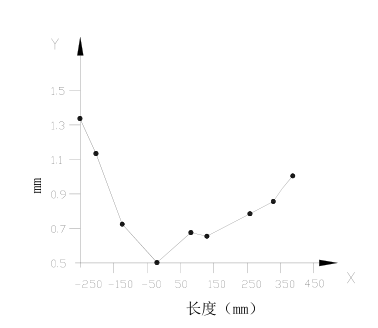

Figure 8 is a pressure path diagram when an injection/pressure holding switch is performed. The pressure difference is about 25 MPa at most. The reason is mainly due to the shape of the plastic part and the limitation of the glue inlet. Molding time of the end of part cannot be consistent, squeezing effect occurs, resulting in a large difference in pressure between squeeze zone and non-backlog zone. Therefore, internal stress is abnormally high, and warpage problem occurs when it cooled. Fig. 9 shows the result of warpage analysis, and maximum warpage deformation reaches 1. 3 mm.

Figure 8 Stress path graph

Figure 9 warp path graph

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Coffee Maker Plastic Housing Mould Suppliers