USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part function: single-head centrifugal fan sheet blades for purifier

Part size: 50*500mm

Mould steel: 718H

Mould base: P20

Mould cavity: single

Ejection system: ejector pin

Delivery time: 45 days

SWY MOULD is committed to the development and manufacture of plastic fan blade moulds. Application areas include cooling fans, blowers, centrifugal pumps, air conditioners, etc. Through the continuous accumulation of technology, we have mastered different types of fan blade mould solutions.

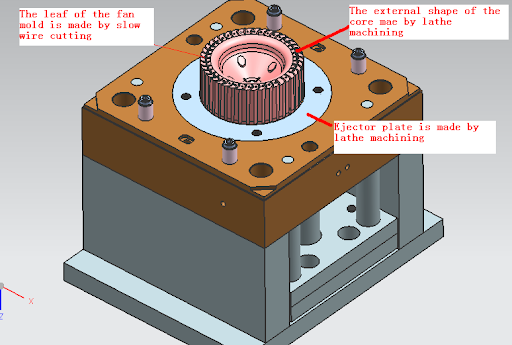

Plastic single head centrifugal fan blades mould tooling equipment

Due to its strong mould tooling capacity and wide mould tooling range, SWY has success among the fan mould tooling supplier and is always the special one who challenges the world-leading mould tooling capacity, first-class quality standard, and latest mould technology skills.

We use high-quality tooling equipment to gain high precision moulding tooling effect and therefore, keep the best position of high-quality China mould maker.

SWY strict quality control system also thanks to the equipment that can give fine data feedback for each tooling finished. See the process inspection report, you can understand our accurate and perfect mould quality.

For this fan blade mould, we use different tooling equipment to make it. For the leaf part, SWY uses the slow wire cutting machine to process, for the external shape, we use the lathe machine to process, for the ejector plate, we use a lathe machine also. Also, there is more need to be machined by different tooling equipment.

The most important point of a plastic centrifugal fan blade mould

The most important point to make a centrifugal fan mould is the concentricity of the fan blade. The centrifugal fan usually consists of 30 to 50 leaves.

Then how to control the concentricity of the centrifugal fan mould?

Concentricity of the centrifugal fan mould is made from two sides, cavity and core. For the cavity of centrifugal fan mould, we make it by circular insert and embed it in the mould base, which the circular insert can be machined by numerically controlled lathe. The core side of the centrifugal fan mould, consist of an ejection plate and core insert. The ejection plate we make as the circular ring can be machined by a numerically controlled lathe, and the core insert made it a circular column can be made in the same way. The leaves of the centrifugal fan on the core insert are made by slow wire cutting. Slow wire cutting machine cut the external surface 4 times to find the centre of the core. The leaves made by wire cutting is very smooth, no need to do any polishing. There’s much other detail should concern to make the centrifugal fan mould, usually one of the processes is the wrong made, the mould is no longer useful.

Mould quality control system in SWY MOULD

SWY MOULD emphasises a lot on upgrading the team's quality philosophy in the whole management process. We have a clearly defined quality policy that guides in day to day decision making. The policy takes into account the needs of the company and the needs and expectations of its customer. Just like the Chinese old saying:" Nothing can be accomplished without norms or standards." SWY possess quality plans which explain the methods and sequence of activities that should be followed in the production in order to ensure that all are to be of the highest quality and meet customer's requirements. We have appointed a quality representative whose authority and responsibilities are clearly defined and documented. We try the best we can to avoid the mistake happening. But when quality problems arise in the company, people also know to whom this problem should be addressed for resolution. We continually evaluate training for employees who have an impact on the quality of products and services. Meanwhile, the company possess training file for its personal and these files are continually updated. It demonstrates that a person holding a position that impact quality meet the requirements of that position. SWY MOULD follows a series of standards during the whole process of manufacture, from the product design to mould design, from tough milling to finished milling, from mould assembling to mould trialling.

Following is the QC list:

* Document and data inspection

* Moldflow analysis standard

* Mould structure 3D design standard

* Mould design 2D design

* Steel hardness inspection

* Rough machining standard

* Finished machining standard

* Core and cavity steel dimension inspection

* Core and cavity inspection

* Mould trialling inspection

* Trial report and sample inspection

* Pre-shipment final inspection

* Mold package inspection

The benefits of mold flow analysis

Mold flow analysis can know whether the product has filling problems. For example, whether the product has short shots, bubbles, and unbalanced filling during the injection process can be determined by carefully analyzing the filling curve. In the mold flow analysis, you can change the position of the injection mold gate, injection speed, and other processing conditions, so that you can know whether these problems can be improved or corrected.

Mold flow analysis can know whether the product is full. It can also provide other useful information such as the required maximum injection pressure and clamping pressure to provide a reference for us to choose an injection molding machine.

Mold flow analysis can calculate the efficiency of the cooling circuit. Adding cooling analysis to deformation analysis can increase accuracy. Since the cooling water circuit is difficult to modify once it is completed, this type of analysis is very useful before opening the mold.

Mold flow analysis can predict whether the product is deformed. The absolute value of the deformation is predicted and analyzed. The prediction of the deformation can be used to compare the gate position, wall thickness changes, or design changes.

Mold flow analysis can be used to check and correct problematic mold prototypes. The problem in detecting injection molds is to use mold prototypes to do "short shots". Mold flow analysis can determine which changes will be effective and faster and cost less than mold repair.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Single Head Centrifugal Fan Blades Mould Suppliers