USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: PBT+30%GF

Part weight: 12g

Mold steel: P20

Mold cavity: 4

Cycle time: 19S

Machine tonnage: 150T

Operation method: semi-automatic

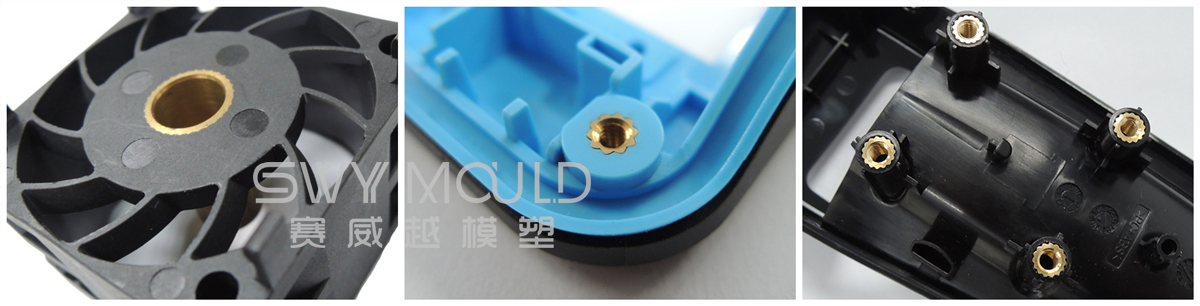

Insert plastic injection molding

For the fan blade part, it needs to rotate when working, the most important matter is to add metal part in the central to realize this function.

When a metal, plastic, or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that SWY MOULD specializes in. With Insert Molding, a part is placed in a mold cavity then selected plastic material is injected directly over it resulting in a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength, and weight reduction.

Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product costs by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single-shot injection machines for Insert Molding, tooling costs are lower than with multi-shot processing.

Injection mould structure animation for your reference

1. Three plate mould

This is a popular design for mould, the advantage is we can make more than one gate for molding and can place the point gate in the center of the product.

2. Insert mould

Usually, we can mold steel pieces, copper nuts, screws in plastic for some special use, such as this plastic fan blade mould.

3. Mould with lifter

The lifter is used to release the undercut in the product.

4. Mould with submarine gate

The submarine gate mark is very small, so we can place the gate on the product surface and the mold can be full automotive.

5. Submarine on ejectors

When we can not find a good position for the gate, we make cut the ejectors and put the gate there.

6. Hot runner mould

The hot runner can save the material for a runner, reduce the cycle time and improve the production quality.

7. Thread release mould

The core will remote itself and release the thread.

8. Mould with the slider: slides for the under release

9. Mould for hubs

10. Sleeve ejector mould

A sleeve ejector is a good solution for long bosses which have a hole in the center.

The mold design process in SWY

SWY is devoted to plastic parts development and mold design. Design for manufacturability and efficient production is our primary objective.

Products design can be according to customers’ samples or drawings. With advanced CAD/CAM/CAE systems, such as Pro-Engineer, Solid works, UG, Cimatron, MoldFlow, AutoCAD, and PowerMill, etc. The drawings can be finished in 2-4 days and are sent to customers for checking before tooling.

We communicate and fully cooperate with customers on drawings analysis and modifications. All the necessary technical drawings will be sent to customers for mold maintenance in the future.

Drawings formats can be DWG, PRT, X_T, IGS (IGES), STP (STEP), SLDPRT, DXF...

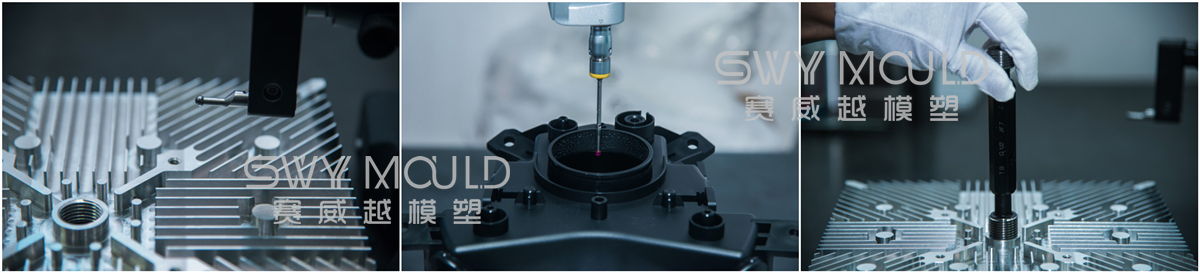

The quality control process in SWY

Quality is the essential factor from where customer satisfaction arises. To meet customer’s requirements, we have established an independent QC department equipped with advanced inspection machines to set up an adaptive and cost-effective approach using the best processes for each step, which include:

1. Mould design control

2. Mould steel hardness inspection

3. Mould electrodes inspection

4. Mould core and cavity steel dimension inspection

5. Mould pre-assembly inspection

6. Mould trial report and sample inspection

7. Mould pre-shipment final inspection

8. Export mould package inspection

9. Quality Control facilities:

* CMM

* Optical Image Measuring projector

* Hardness Tester

About our SWY MOULD

Taizhou Saiweiyue Mould & Plastic Co., Ltd. is located in Huangyan District, Taizhou City, Zhejiang Province, the hometown of Mould in China. It is only 20 minutes drive from Taizhou railway station and 40 minutes drive from Luqiao airport, with superior geographical conditions, convenient transportation, and convenient logistics. The company adheres to the business philosophy of "quality first, customer satisfaction, continuous innovation ". After more than ten years of pioneering and enterprising, has developed into the production of a plastic injection mould manufacturing company. In the mold production of the company, single construction, full-size inspection, overall installation, and other methods are adopted according to the drawings, so that the whole mold production process is synchronized and simplified. The company continues to introduce advanced equipment. Mold manufacturing and processing to achieve CAD design, CNC milling, three-dimensional coordinate detection of three-dimensional integration, to ensure the quality of the mold. Have perfect quality control and after-sales service quality tracking system. We can provide customers with drawings, samples, and customized moulds, and provide customers with injection parts processing, equipment, and related processes. "The pursuit of excellence, create first-class" is our service concept. SWY MOULD is looking forward to cooperating with you, developing and growing together.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Fan Blades with Insert Molding Suppliers