USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Product description: Fan Blade

Product size: 300*300*180 mm

Mould cavity: 2 cavity

Suitable machine: 650 ton

Mould main material: S136

Mould injection system: Anole hot runner

Mould ejection system: eject plate

Mould cycle time: 20 seconds

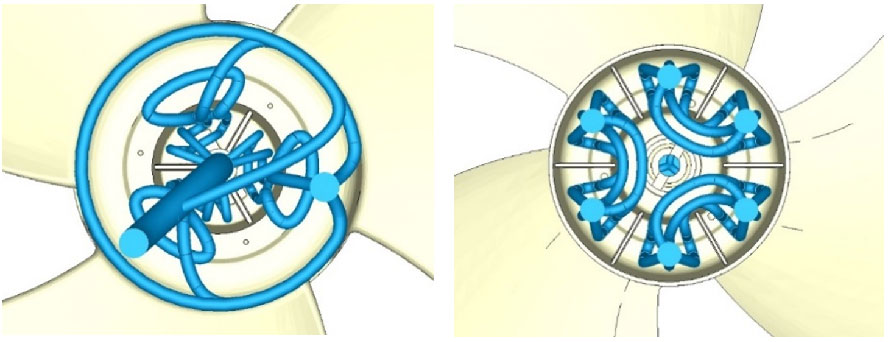

Mould features: multi-slider movements, high precision & balance test passed

The characteristics of electric fan plastic blade mould

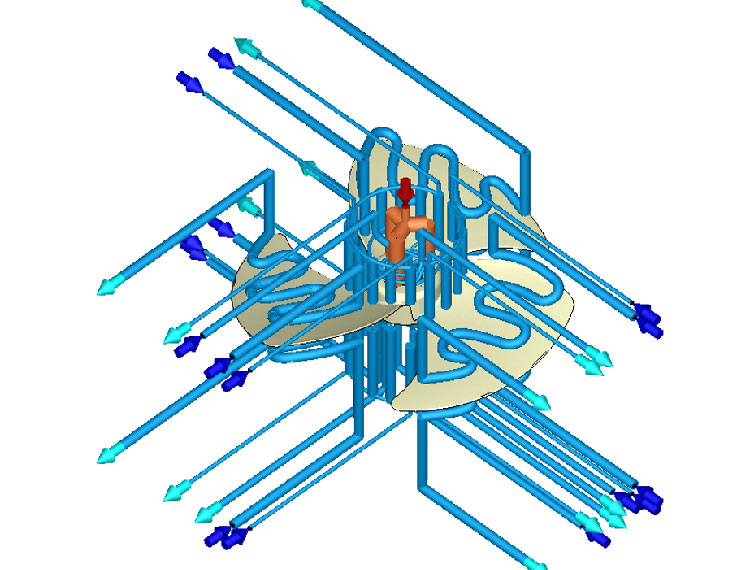

1. Injection mould having the conformal cooling system in particular cooling at the center hub, using conformal cooled core and cavity inserts built by SLM (Selective Laser Melting) process.

2. Injection mould equipped with a hot runner system using 3 pin-point gate positions to ensure a uniform flow of plastic into the mould. This resulted in well-balanced blades having good strength. No reworks of the part are required.

3. Injection mould that can inject blade parts with SAN (Styrene-acrylonitrile) material at an increased production rate of 145 pieces per hour even at a higher water temperature of 30oC compared to the company’s traditional water temperature settings of 15-18oC. This represents a 45% increase in productivity compared to those of the original molds.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Electric Fan Plastic Blade Injection Mould Suppliers