USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: HIPS(high gloss)

Part dimension(mm): 790*225*170

Shot weight: 570g

Mold weight (T): 14T

Mold cavity steel: 1.2083

Mold Core steel: 1.2344

Cycle time: 42 seconds

Manufacture time (day): 75 days

Cooling line connector type: DME NS350 SERIES quick coupling, excellent cooling system design, the cooling design will as many as possible to cooling best.

Hot runner system in plastic AC cover molding

The cold runner of a mold refers to the section between the mold cavity and the gate. The molten plastic maintains its fluidity inside the runner by virtue of the injection pressure and its own heat. However, as a part of the molding material, the runner is not any part of the product. As a result, when designing a mold, we need to consider not only the filling but also the material-saving production by shortening or downsizing the runner; in fact, it is very difficult for us to have both through the cold runner, but hot runner system can solve this problem.

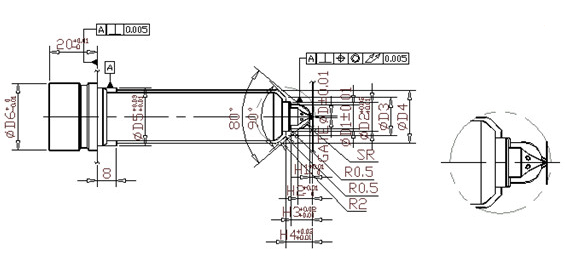

When using the hot runner, the proper selection of gate type is very important, because gate type directly determines the selection of hot runner components as well as manufacturing and designing of molds. Therefore, the hot runner can be classified into 3 types based on the gate type, i.e. (1) hot tip hot runner system, (2) sprue gating hot runner system, and (3) valve gating hot runner system.

1. Hot tip hot runner

It is the most widely applied hot runner since each hot runner supplier provides this system. Though systems from different suppliers feature different nozzle and nozzle insert of different shapes and sizes, they work precisely the same way, which is precisely adjusting and controlling the molding temperature at the gate through a method that combines the insert hot tip at the front of the nozzle with the cooling system.

The hot tip hot runner system can be used for the majority of plastic molding materials, such as PP, PE, PS, LCP, PA, PET, PBT, PEEK, POM, PEI, PMMA, ABS, PVC, PC, PSU, and TPU, etc. Generally speaking, the hot tip gate is used to produce medium and small-sized parts, esp. suitable for the production of macro parts. The sectional diameter of the gate usually is between 0.5mm and 2.0mm.

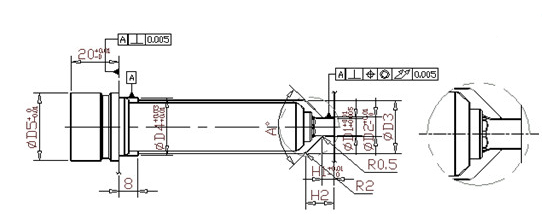

2. Sprue gating hot runner

In the sprue gating hot runner, the molten plastic enters the mold cavity through the open pipe. Melt flow pressure loss in the gate area is very small. The sprue gating hot runner system is more suitable for the production of medium and large-sized parts. the gate mark will be more visible due to the larger size. So, the sprue gating hot runner system is usually applied to internal products or components that do not have high requirements on gate marks appearance. Also, the sprue gating is often used in combination with the cold runner, i.e. taking the sprue nozzle as the main runner and sprue, and designing the sprue gating along with the cold runner. In the application, the sprue gating can be made bigger for smooth flowing, because the gate marks on the cold runner are not important.

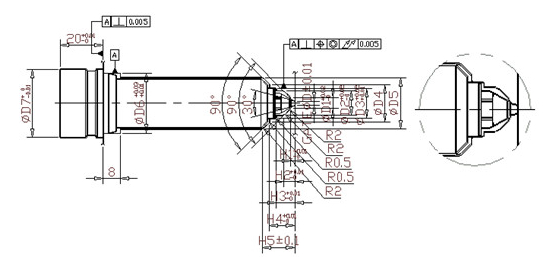

3. Valve gating hot runner

The valve gating hot runner is another hot runner system that is supplied by global mainstream hot runner companies. Through the valve pin controller, this needle system mechanically opens or closes the gate at the pre-set time. This type of hot runner possesses the advantages of the previous 2 systems (Hot Tip Hot Runner & Sprue Gating Hot Runner ), such as controlling the gate open/close time manually, allowing a smooth and glossy gate mark, and expanding the hot runner application.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Front Cover Molding For Wall Mount AC Suppliers