USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Type: wall-mounted

Product size: 1185*345*245mm

Thickness: 3.5mm

Raw material: HIPS

Mould steel: NAK80

Mould base: P20

Cycle time: 70S

Shot weight: 1972g

Runner system: hot runner Chinese local brand

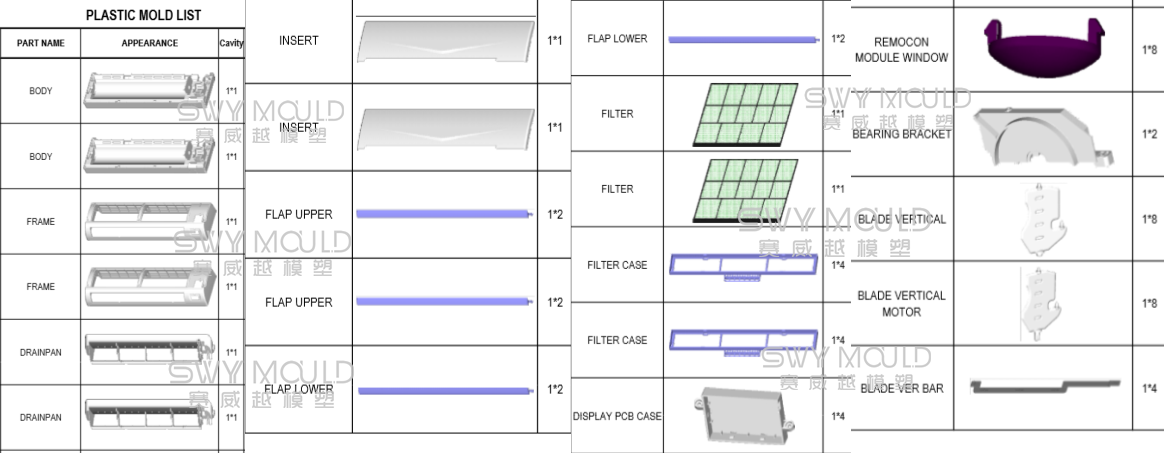

All plastic parts of air conditioner which our customer sent us for quotation before

Later if you have any project about air conditioner part plastic injection moulds, kindly send us the pictures with the size of each part and your requirement on the parts and moulds.

Technology for air conditioner plastic injection mould

1. High-speed machining technology is widely used

High-speed machining, generally used for large-scale air conditioner mould and its surface machining accuracy can reach 0.01mm. The high-speed milling and finishing of the air conditioner mould surface can be used only with a little polishing to save a lot of time for grinding and polishing. High-speed machining significantly shortens the molding cycle, thereby increasing the market competitiveness of the product.

SWY MOULD uses CNC high-speed milling, with five-axis linage, and spindle rotation is generally 15000-30000r/min. In addition, SWY also attach great importance to equipment renewal, equipment depreciation period is generally 4-5 years. The addition of CNC high-speed milling machines is one of the key points of equipment investment in mold enterprises.

2. High-speed scanner and mold scanning system

This system provides many functions required from a model or physical scanning to processing the desired model, greatly shortening the development and manufacturing cycle of home appliance mould. Some fast scanning systems can be quickly installed on existing CNC milling machine centers to achieve fast data acquisition, automatic generation of various CNC milling machine centers to achieve fast data acquisition, automatic generation of various CNC system processing programs CAD data in different formats, and reverse engineering for mold manufacturing.

Maintenance specification for air conditioner plastic front case injection mould

Maintain the mould can be separated into 3 parts: before, during, and after the production.

1. Before

* Scrub the dust, oil, and rust of the mould, and remove the dirty on the surface before putting the mold inside the injection molding machine.

* Use an air gun or rag, detergent, or alcohol to clean the oil on the mold surface.

* Check the mold's cooling channel to ensure smooth water passage.

* Check whether the arc on the mould gate sleeve is damaged and whether there is any remaining foreign matter. If necessary, clean it up.

* Moving parts: such as thimbles, springs, hydraulic cylinders, sliders. Check whether there is rust, bending, or fracture, and make sure the movement must be smooth.

2. During production

* The moulds produced on the machine are inspected and maintained daily.

* Check the mould guide post, guide sleeve, and sliders for damage and foreign matter on them, and refuel them once a day.

* Clean the mould parting surface and the foreign matter in the exhaust groove, oil stains, and wipe it with an air gun or rag, detergent or alcohol once a day.

3. Maintenance of mould after production

* Inspect each part of the mold to see if there is any damage.

* Clean the greasy dirt on the parting surface and the debris in the mold cavity, and spray with an anti-rust agent.

* Blow off the water remaining in the cooling water channel.

4. Precaution

* Always wear labor protection supplies when maintaining the mould. Heavy objects must be operated with a crane. It is strictly forbidden to lift the mould directly by hand to prevent inquiry to the limb.

* The rust prevention of the mold is necessary. After the mould is maintained, special attention should be paid to the rust prevention action of the mould. The remaining water in the water channel must be dried with an air gun.

* Too much lubricating oil does not bring a better lubricating effect, just the right amount.

* When the mould is installed and maintained, pay attention to the numbers and directions of the inserts and other components. Do not install them incorrectly. Check whether the screws are completely used up and tighten them diagonally when installing the screws.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Air Conditioner Plastic Front Case Injection Mould Suppliers