USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Bucket resin: PP

Part size: 160*160*160mm

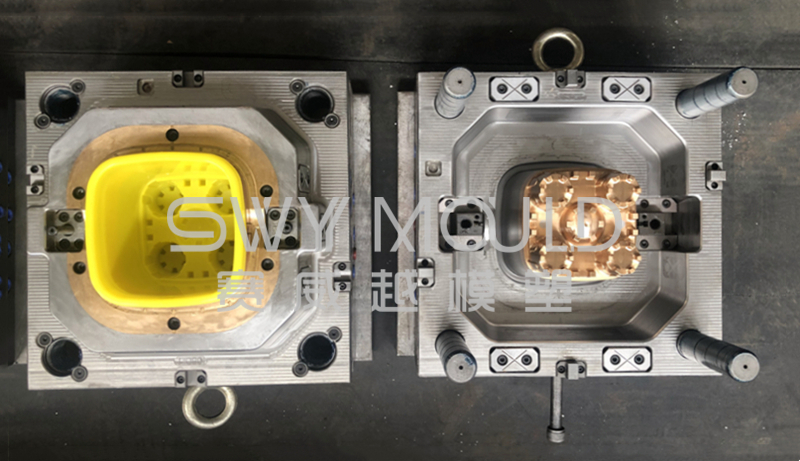

Mould steel: 2344 vacuum hardening + beryllium copper

Mould base: 60#

Injection system: hot runner 1 drop

Mould size: 380*430*330mm

Mould weight: 360KG

Manufacturing method: HIGH-SPEED MACHINE 200T WITH ROBOT

How to make a good quality playing sand plastic square bucket mould?

In order to produce a high-quality square bucket mould, attention should be paid to the details of many links, and the most important of these are the following three points:

1. Bucket mould design and structure

A high-quality mould structure is a premise for a qualified plastic bucket mould. We attach great importance to analyze mould structure, including demolding draft angle, the epitome of the product surface, gating system design, exhaust design, cooling system design, etc. The main problems that may easily occur will through trial and error during the mould structure design.

2. Bucket mould material

In order to improve the mould life and product quality, we increase the mould steel hardness through heat treatment. The steels we commonly use are H13(48-52HRC), 2316(45-50HRC), etc. to prevent mould eccentricities, we use a whole piece of steel to make the bucket. The cooling system is very important. We adopt a single loop cooling way and set up even distribution water channels as much as possible. All small sliders will be nitrided to increase the hardness.

It is important to keep maintenance for the bucket moulds. We should check and make sure the water channels and air circuit unlocked.

3. Bucket mould cooling system

Cooling system design is a relatively cumbersome work, namely to consider the uniformity of the cooling and the cooling effect, also the impact brings to the overall mould structure, determining the exact location and size of the cooling system; and cooling for key positions such as moving plate or the inserts, side sliders as well as side cores; standard cooling element design and the selection of the cooling standard components. Also for this bucket mould, SWY adds the beryllium copper to suit the customer's high-speed injection molding machine. As the below picture shows, the bronze part is the beryllium copper.

The advantages of using hot runner in square bucket mould

Plastic moulds are tools that are matched with plastic molding machines in the plastics processing industry to give plastic products a complete configuration and precise dimensions. According to the different pouring systems, the mould can be divided into three nozzles, small nozzle mold, and hot runner mould. The advantages and disadvantages of them are different. Here SWY MOULD introduces the hot runner system in bucket mould advantages.

1. No spout material, no post-processing is needed, the entire molding process is fully automated, saving working time and improving work efficiency.

2. Low-pressure loss. The temperature of the hot runner is equal to the temperature of the injection nozzle of the injection molding machine, which avoids the surface condensation of the raw materials in the runner, and the injection pressure loss is small.

3. The repeated use of nozzle materials will degrade the performance of plastics, and the use of hot runner systems without nozzle materials can reduce the loss of raw materials and thus reduce production costs. In the cavity, the temperature and pressure are uniforms, the plastic parts have low stress and uniform density. Under a smaller injection pressure and shorter molding time, the product is better than the ordinary injection molding system. For transparent parts, thin parts, large plastic parts, or high-demand plastic parts, it can show its advantages, and it can produce larger products with smaller models.

4. The thermal nozzle adopts a standardized and serialized design and is equipped with various optional nozzle heads, which have good interchangeability. The uniquely designed and processed electric heating coil can achieve uniform heating temperature and long service life. The hot runner system is equipped with hot runner plates, temperature controllers, etc., with exquisite design, diverse types, convenient use, and stable and reliable quality.

Here is the hot runner system SWY uses for our customer:

The relationship between mould life and mould cost

It is difficult to distinguish the difference between the life of the mould and the "direct cost of the mould". In the technical and management measures taken, it may happen that the life of the mould and the cost of the mould increase simultaneously with a small difference. For example, the use of high-quality and high-priced mould materials or advanced processing technology increases the life of the mould but also increases the cost of the mould. In this case, it is still recommended to use high-quality and high-priced mould materials or advanced processing technology to manufacture the mould. Because the mould has a long life, the indirect costs of replacement, high speed, and maintenance are reduced, which is cost-effective from the perspective of comprehensive economic indicators. In addition, the development space of new materials and technologies is large, and the potential is further tapped in the process of continuously accumulating experience.

The life of the mould is closely related to the cost of the mould. The two are mutually restrictive and mutually reinforcing. Any one of these factors cannot be overemphasized. It must be specifically analyzed according to the actual production and specific measures can be taken to obtain economic benefits. It is necessary to comprehensively analyze the relationship between the mould cost and the mould life, compare the technical and economical aspects of multiple schemes, and optimize the scheme.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Playing Sand Plastic Square Bucket Mould Suppliers