USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: PP

Four shapes with a size around 100*80mm

Cavity/core steel: P20

Mould base steel: 60#

Mould cavity: 1+1+1+1

Runner type: cold runner

Cycle time: 25S

Mould size: 430*440*435mm

Mould weight: 480KG

Kids love to build sand castles on the beach or in the backyard sandbox, especially when they are equipped with the right sand play tools. Our customers know the importance of these sand castles, asking us to make a plastic injection mould to produce these castles.

Injection mould making supplier in China---SWY MOULD

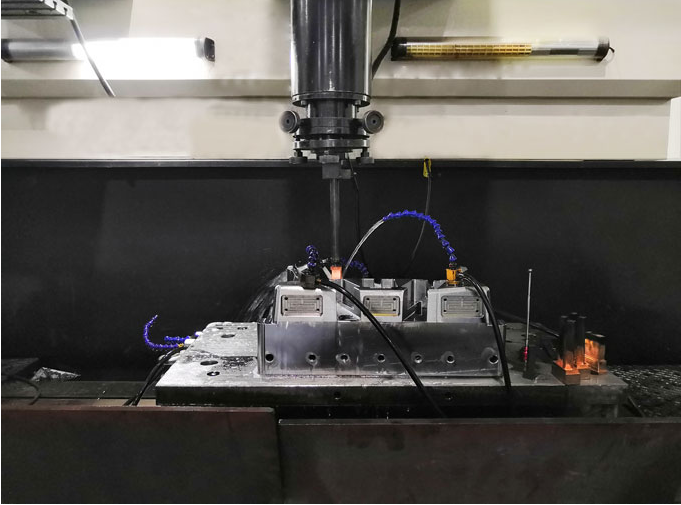

SWY MOULD is an injection moulding company located in Huangyan, Taizhou, China. We provide a one-stop injection mould-making service. We have more than 10 years of experience in the plastics manufacturing industry. In order to provide high-quality injection mould, we equipped an advanced series of equipment such as a CNC machining centre, engraving machine, spark machine, wire cutting, grinding machine, milling machine, drilling machine, and lathe, etc. Below is something you need to know about SWY MOULD injection mould making.

1. Mould materials used in injection mould making

According to the working conditions and characteristics of plastic injection mould tooling, there are 5 requirements for mould materials used in plastic tooling:

* Steel material needs to be very pure to obtain a highly finished processed surface. Therefore, fewer inclusions, less segregation, dense structure, and high surface hardness are required.

* The surface should be wear-resistant and resistive, and it is required to have a certain surface hardening layer. Generally, it should be above 45HRC, and the surface finish should remain unchanged for a long time.

* It has sufficient strength and toughness to withstand the load without deformation or damage.

* Heat treatment deformation is small to ensure interchangeability and matching accuracy.

* It has good electrical processing capabilities.

2. Mould steel that SWY frequently used

Swedish 8407, US S136 and 420&H13, 2316&2344 and 083 of Europe, LKM2316, LKM738H, 1.2083, 1.2312, 1.1730, H13, P20, MOLDMAX-HH, etc.

Basic requirements for SWY injection mould making

In the production of various industrial products, the mould application is to ensure the product quality, increase its productivity and reduce costs. Therefore, in addition to the reasonable mould design, the selection of reasonable mould structure, the high-requirements injection mould manufacturing technology is also needed.

1. High manufacturing precision

In order to produce qualified products and play the role of injection mould tooling, the mould design and mould making must have high precision. The mould accuracy is mainly determined by the accuracy requirements of plastic parts and the mould structure. In order to ensure the accuracy and quality of the injection moulded parts, the precision of the mould working part is usually 2 to 4 higher than that of the injection moulded parts. The mould structure has relatively requirements for the cooperation between the upper and lower moulds, and the mould components must have sufficient manufacturing precision, otherwise, the mould will not be able to produce qualified products, and even the mould cannot be used normally.

2. Long service life

Plastic injection mould tooling is relatively expensive process equipment. The plastic mould costs account for about 10% to 30% of the overall cost, and its service life will directly affect the injection mould making costs. Therefore, in addition to special cases such as low volume injection moulding and new product trial production, etc, the mould generally requires a long service life. In the case of large volume injection moulding, the mould service life is especially important.

3. Injection mould making cycle

The injection mould making cycle is mainly determined by the level of manufacturing technology and production management. In order to meet the production needs and improve the competitiveness of the product, it is necessary to shorten the injection mould making cycle as much as possible under the premise of ensuring quality.

4. Plastic mould cost

Plastic mould cost is related to the complexity of mould structure, the mould material, the mould manufacturing precision requirements, and the processing method. Engineers of injection moulding companies must reasonably design mould and formulate mould processing process according to the requirements of injection moulded parts, and strive to reduce plastic mould manufacturing cost.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Kid Beach Sand Castle Mould Suppliers