USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

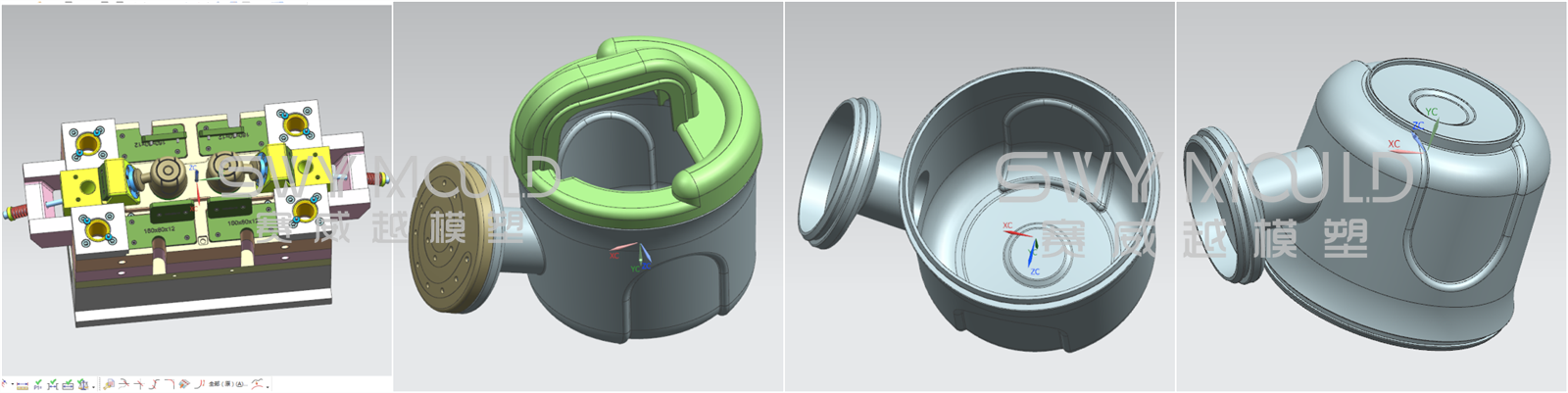

Raw material: PP

Part size: 100*80*70mm

Steel material: P20

Mold base: 60#

Nos. of cavity: 2

Injection system: cold runner

Mold size: 580*370*790mm

Mold weight: 680KG

Suited machine: HAITIAN MA1600 or MA900

Injection mould design ability in SWY MOULD

1. A good mould design is an important key to producing a mould of high quality. So, SWY performs different analyses to ensure the tool achieves a good mould design.

2. We perform design for manufacturability analysis to ensure the tool designing fulfilled the manufacturing requirement of the customers.

3. We can provide professional suggestions on the tool designing to enhance the moulding effectiveness.

4. We can also provide optimized molds for rheological properties and material filling mold flow analysis products.

How to achieve a successful injection mould design?

1. Optimal mold cavity layout.

2. Appropriate mold base size and guiding method.

3. Appropriate cooling layout.

4. Calculate the shrinkage rate of the material.

5. Study the two-dimensional design of the product. The required tolerance determines the way of design and processing.

6. Correct ejection distance and demoulding method.

7. Minimal cycle time of injection molding and as much automation as possible.

8. Appropriate gate location and parting line location.

9. Minimum clamping force requirement, minimum pressure value. (Injection molding machine requirements are smaller, and injection molding costs will decrease)

10. Proper exhaust and reliable sealing.

11. The lowest scrap rate. (the most important factor affecting the actual cost)

12. Appropriate selection of steel and heat treatment, only to meet customer requirements.

13. Pay attention to the special functions of the slider and the inclined top to ensure that all the designed mechanisms operate well.

About our Taizhou Saiweiyue Mould and Plastic Co., Ltd

We are a company dedicated to the manufacture, commercialization, and export of moulds for the different plastic industries. Our experience allows us to offer molds of excellent quality and delivery times that fit your requirements. To achieve all this, we integrate innovative processes together with a competent human resource, aimed at obtaining high levels of productivity and excellent quality.

1. Mision

Provide the customers with the best up-to-date solution for the manufacture of plastic articles of high quality and with high efficiency.

2. Vision

We expect to be positioned in the international market as a professional company in the manufacture of plastic injection moulds, taking advantage of business opportunities with aggressiveness and prudence and intensifying efforts to ensure the permanence and loyalty of customers.

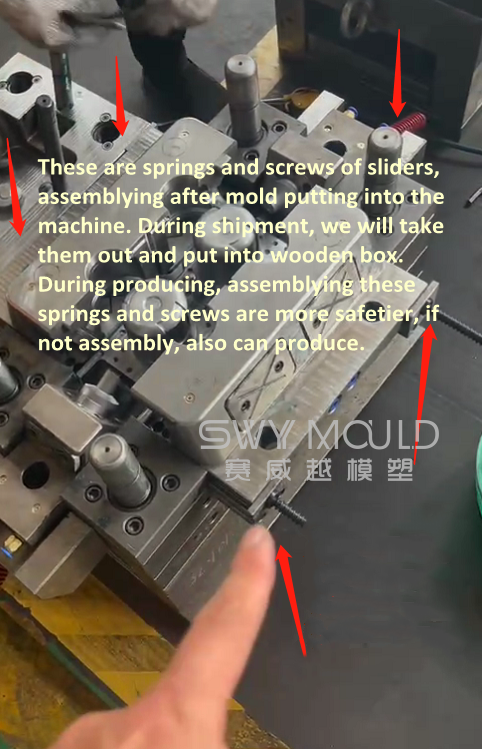

Shipment of plastic injection mould of child watering can

1. After we get our customer’s confirmation for shipment, we attach a plate to the mould: this shows the product’s serial number, production year, and mould information.

2. At this stage we paint the mould with anti-rust oil, then we wrap it safely in a plastic bubble bag for protection.

3. Then we label the package as necessary to ensure that it reaches you safely.

4. We put the package in a wooden case to protect it during shipping.

5. We label the wooden case carefully to ensure that your order reaches you safely and quickly.

6. Any others need to pay attention to we will make a file and print, send with mould together.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Injection Mould Of Child Watering Can Suppliers