USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

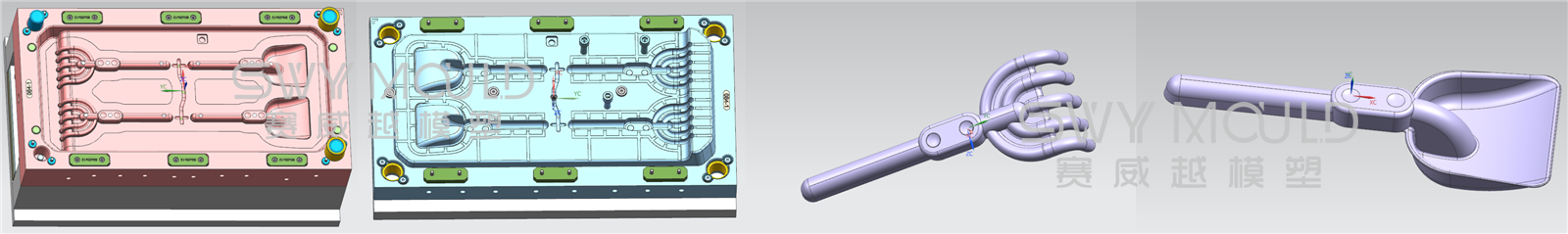

Shovel dimension: 250*90mm

Rake dimension: 230*90mm

Raw material: PP, food-grade

Mould steel: P20

Mould base: 60#

Nos of cavity: 2+2

Injection system: cold runner

Mould size: 675*400*400mm

Suitable machine: MA900 or MA1600

Why choose our SWY MOULD to be your business partner?

Because you will find that it will be a wise decision you have ever been made that you choose SWY MOULD to be your business partner and supplier. It is sure that the mold maker saves cost and brings you big profit.

1. Innovative engineering and design

2. Knowledge and competitive price

3. Decreased cycle time

4. Minimal service requirements

5. Reduce resign consumption

6. Weekly project schedule report

7. After-sales service

8. Plastic injection molding services, we have several injection molding machines.

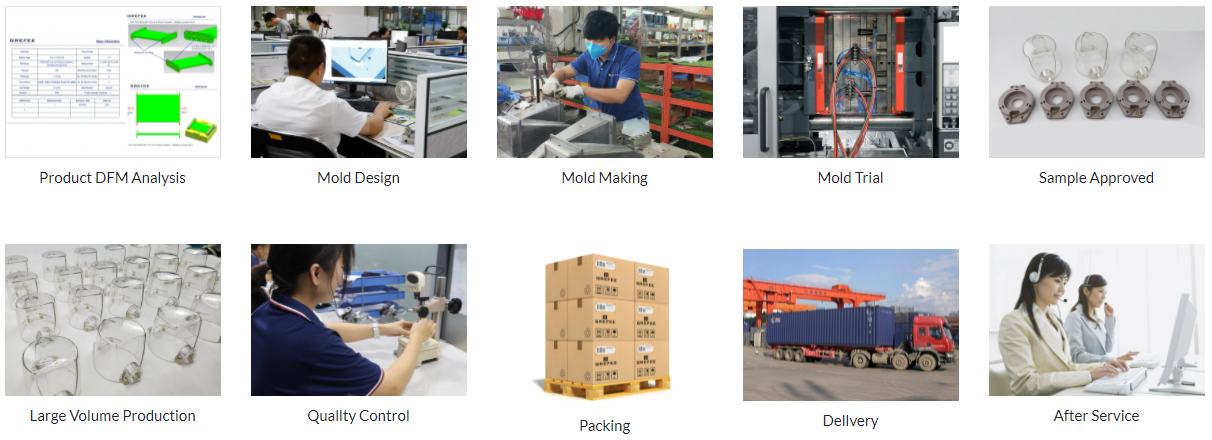

Plastic gardening soil spade injection molding making process

Strictly follow the project flow, make sure the manufacturing plan working efficiently and flexibly, with QC control in every step, guarantee project completing in a quality and punctual way.

Provide complete design solution

SWY MOULD provides complete design solutions and provides customer support in all product development cycles. If you have a new idea, we will explore innovative solutions based on your ideas, from concept sketches to comprehensive engineering and marketing solutions.

Our technical team draws on many years of experience and cuts in from multiple fields to develop a successful mold product. We analyze the design of parts for all new projects, apply experience designed for production, maximize mold capabilities, minimize secondary operations, reduce assembly time and simplify positioning. At every stage, we do our best to make the perfect combination of materials, manpower, machine efficiency, cost-effectiveness, and production.

We are proud that many partners have worked on difficult projects. We introduce innovative solutions to ensure a successful and timely product launch. It is always emphasized that customers are fully involved early in the project, ultimately saving time and costs and avoiding possible problems.

As part of our design and manufacturing services, we can recommend the right plastics and additives for your product needs.

We are very experienced with various polymers, whether common or unique materials. If you need guidance on material selection, please contact us.

As a customer, you can make your requests. We provide personalized design services to ensure you achieve your goals. We use many years of industry experience to ensure that your design will eventually become the product you want, and be made efficiently by SWY MOULD.

Steel selection for plastic gardening soil spade injection molding

Many people do not know how to choose the right steel for the production of injection molds. Choosing good, expensive, afraid of overkill. Poorly selected, cheap, and afraid of made plastic products can not meet the expected requirements and mold life. In fact, this is really the case, choosing the right steel is really crucial.

The first injection mold is the mold of our most common plastic daily necessities. Because most of the daily necessities do not have excessive requirements on mold precision, wall thickness, appearance, etc., plus the replacement of daily necessities is relatively fast, so the life expectancy of the mold is not very high, so generally choose 718 or P20 steel materials.

Another ultra-thin box mold is a typical example. It seems to be simple in appearance, but the requirements for steel are very strict. S136 is generally used. Because the ultra-thin box requires a high wall thickness and is a high-speed running mold. The anti-corrosion performance of S136 satisfies the requirements of the ultra-thin box size. The hardness of S136 meets the requirements for high-speed operation. Therefore, the ultra-thin box must choose S136 such as hardened steel. At the same time, the copper on the core can better achieve the cooling effect.

There is also a plastic knife and fork spoon mold, the plastic of the cutlery spoon has two kinds of PP, PS. H13, S136, 2344, 2316 can choose a variety of steel materials, but most customers open a pair of molds to do two materials, we will make the mold according to the plastic shrinkage ratio of PS, generally using H13 steel.

If you are still confused about it, welcome to contact our SWY MOULD, we will give advice according to your products.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Gardening Soil Spade Injection Molding Suppliers