USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

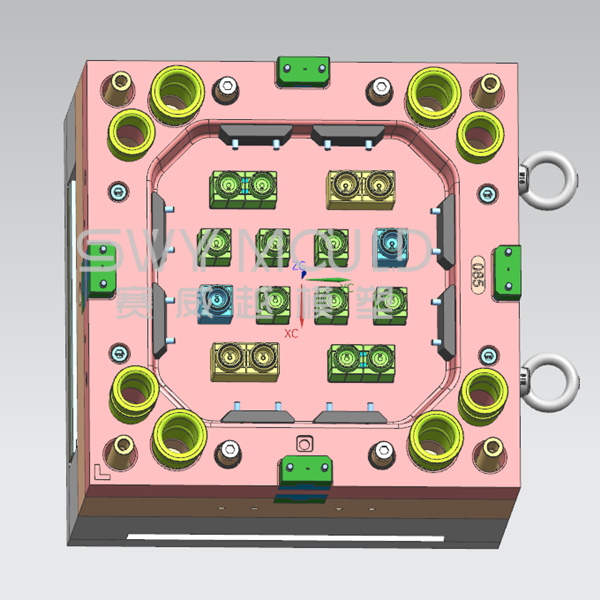

Part size: 31*31*53mm & 62*31*53mm

Plastic resin: PP

Mold steel: P20

Mold base: 60#

Mold cavity: 8+4

Injection system: cold runner

Mold size: 420*420*450mm

Mold weight: 530KG

Toy blocks, also called "building blocks," are solid shapes used for construction play. Some are simple planks made of wood. Others are fancy, like the interlocking bricks of plastic made by Lego and MegaBlox, made by plastic, such as ABS, PP, etc.

But whatever form they take, blocks can function as powerful learning tools. Studies suggest that toy blocks can help children develop:

* motor skills and hand-eye coordination

* spatial reasoning

* cognitive flexibility

* the language skills

* a capacity for creative, divergent thinking

* social competence

* engineering skills

There is also evidence that complex block-play is linked with higher mathematical achievement.

Research confirms what kids, parents, and teachers have known for centuries: playing with blocks is not only fun, it’s also really, really good for learning. Blocks teach physics concepts like cause and effect, force, velocity, and gravity. They also help develop emotional growth and resilience and provide opportunities to explore imagination and visual-spatial relationships.

There are many shapes of construction blocks in the market, also early eduction, need different shapes and sizes of the blocks which help children learning. But for some customers who have little investment but want to work with this business, multiple cavity mold is a good choice.

Multiple cavity mold

Multiple cavity mold means the number of cavities greater than one, which means that has more than one part in an injection mold, It is usually professional to say cavity, one cavity, or two cavities, for example, this mold is made with 8+4 cavities means one molding cycle to mold 8 single blocks and 4 double blocks with the same part feature, dimension, shape, size, etc.

The considerations of making multiple cavity mold

When do we need multiple cavity molds?

There are some factors to make decisions before starting to make your plastic mold.

1. The size of the product

2. The number of the product requirement

3. The size of the machine, if you only buy plastic molded parts then you do not need to care about this point, SWY MOULD will check this.

If the size of the product is small, such as the toy mold of snowflake brick, which usually makes 24 or 48 cavities, you must say why not make 30 or 40, this is because for the balance mold layout and material filling balance, especially when you use cold runner mold. so normally multi-cavity mold is 4, 8, 16, 24, 48, 96 cavities are better options.

When we make multiple cavity mold and the cavities are more than 24, we normally suggest making hot runner mold, one part per hot-drop, at least to use 6 hot runners to the cold runner, which means four cavities per hot drop. this could save the cycle time and keeping the best quality of injection molding parts.

The advantages of making multiple cavity mold

The reason we make a multi-cavity mold is simple, we need to save production unit cost for each plastic molded part, for example, 160-ton injection machine the production cost is 0.8 USD per shot, if use 8 cavity mold to produce the parts, then the production cost is 0.1 USD per part, if you use only 2 cavity mold to produce the parts in this machine, the unit production cost is 0.4 USD, if you require one million or more parts, you can image how many costs you can save from 8 cavity mold, that is why multi-cavity mold is so welcome to the customers.

The disadvantages of making multiple cavity mold

We all know that all of the customers prefer the multiple cavity mold since this can save lots of production cost, but there are other factors you need to think about before making a decision because make a plastic mold is not cheaper, make a multi-cavity mold is more expensive, some times double or even 3 times expensive than a single cavity or two-cavity mold, for example, if you make large cavity mold, need to use hot runner drops for the mold, the hot runner cost is higher, and this cost some times is enough to make 2 cavities cold runner mold since there are many cavities in one mold, the mold manufacturing cost is high than the less cavity mold as well, this is another cost, so the total cost is two or three times more is not supprised.

Whether making multiple cavity molds or not, all are decided by your machine tonnage, the sample size, the annual quantity needed, and other factors. If you are not clear about it, welcome to contact our SWY Mould, we would like to help you solve this problem.

Plastic construction blocks molds for early education made by SWY

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Construction Blocks Molds For Early Education Suppliers