USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

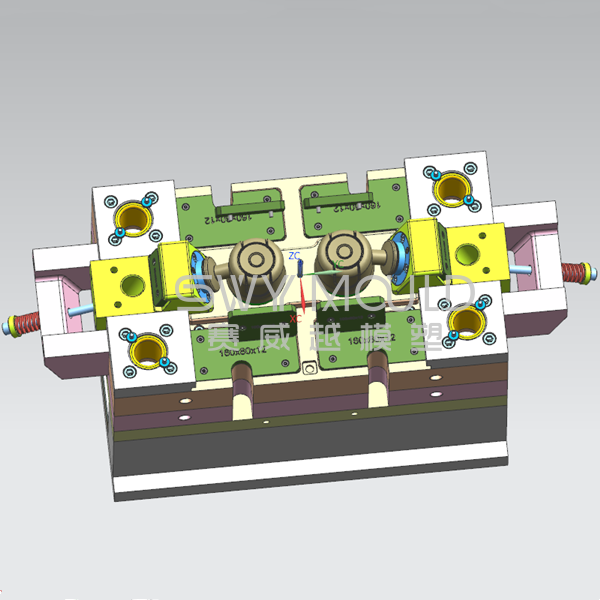

Raw material: PP

Part size: 100*80*70mm

Steel material: P20

Mold base: 60#

Nos. of cavity: 2

Injection system: cold runner

Mold size: 580*370*790mm

Mold weight: 680KG

Suited machine: HAITIAN MA1600 or MA900

The factors which affect the plastic child toy kettle body mold quality

The mold manufacturing process is a complex process. From design, processing, assembly, debugging and other steps, it can be put into use at the end. In the entire life cycle, the factors that affect mold quality mainly include the following nice aspects:

1. Mold steel

Steel is the decisive factor of mold quality, and choosing reasonable steel is the top priority. The criteria for selecting steel are:

* Requirements for injection molding materials

Different plastics should use different steels, such as high polishing requirements, corrosion resistance requirements, etc.

* Price

The steel can be used, not the more expensive the better; considering the cost factor of the mold, the mold steel should choose the material corresponding to the mold life to avoid unnecessary waste; generally the life of P20 is about 300,000; 2738 steel, 500,000 is no problem, H13/2344 is usually more than 800,000-1,000,000, you can choose according to the situation.

* Heat treatment

The surface treatment of the mold is also very important. Nitriding can enhance the surface hardness of steel and effectively extend the life of the mold; electroplating can effectively modify the mold steel, and for some plastic parts that require high brightness and corrosion resistance, electroplating can be used to enhance and improve the performance of the steel.

2. Mold structure design

The mature mold structure not only considers the product material properties-shrinkage rate, molding temperature, elastic tensile deformation coefficient, etc. but also consider the cooling water circuit, the speed of mold opening and closing, etc. A reasonable mold structure can effectively extend the life of the mold and ensure the smooth production of the mold. Improve efficiency and reduce costs.

3. Mold processing

The arrangement of the molding process is particularly important. A reasonable process arrangement can speed up the production cycle, shorten the processing time, and effectively save costs. And more importantly, accurate and reasonable processing can ensure the stability of the mold in the production process and prolong its life.

Some processing errors will cause mold welding, no matter how good the welding is, it is a loss to the mold; in addition, poor processing may also affect the mold operation, reduce the mold life, and cause the mold to crack during the production process. It even breaks.

4. Standard parts

Although standard parts are not directly involved in forming, they control the operation of the entire mold. Good standard parts should be wear-resistant, hard enough, high precision, and not suitable for deformation. The price difference of standard parts of different brands is very big, so don't just bargain the price when making molds.

5. Polishing/texture

The polishing of the mold is the last link in the manufacture of the mold. Polishing is directly reflected on the plastic parts, so this is the most face-to-face job. Polishing can also help and supplement the action of the mold, especially for demolding. Often the production of some molds is not smooth because of improper lighting, excessive resistance, difficulty in demolding, and even whitening and cracking.

6. Mold assembly

The mold assembly is just like assembling a machine. Every component and every screw cannot be wrong, otherwise, the consequences will be very serious, from the slightest to the product defect, affecting the production, and the other to completely damaging the mold and causing scrap. Therefore, the assembly work must be very meticulous. Pay special attention to the cleaning of the mold during the assembly process, especially the waterline and screw holes, and be sure to blow clean the iron filings inside.

7. Hot runner or cold runner

This actually has the least impact on the quality of the mold.

8. Cooling system

Anyone who has mold experience knows how important a cooling system is to a mold. Due to the increase in prices and human wages, .when mass production of products, the profit that does reduce the injection cycle of one second is unimaginable however, while accelerating the production cycle, the temperature of the mold will rise. If it is not effectively controlled, the mold will be too hot to form, and even cause the mold to deform and fail. Therefore, a good waterway design is particularly important, including the arrangement density, diameter, interconnection of the waterway, and so on.

9. Mold maintenance

Mold maintenance is mainly maintenance and maintenance during the production process. If it is not used for a long time without maintenance, it may cause the mold to be scrapped. Therefore, every time the mold is used, comprehensive maintenance must be carried out, especially the rust prevention of the forming part and the rust prevention of the main moving parts. Because the mold needs to receive water during the production process, it may sleep on the mold during the installation or disassembly process, so you must ensure that the mold is dry, and then brush oil to protect it.

Customer requirements on plastic child toy kettle body mold

1. There are no appearance quality defects of plastic parts (such as shrinkage, etc.) or structural problems of injection products (such as parting surface setting, gate setting, the life of injection products can not be guaranteed, etc.).

2. Plastic mold appearance: the appearance of injection products must ensure that there is no rust, no collision mark, no defect of the module such as incomplete frequently.

3. Plastic mold transportation: plastic mold transportation must be loaded with a mold locking sheet, packaging strong, rustproof.

4. Plastic mold information: at the same time as delivery of plastic mold, a complete set of plastic mold wearing parts and maintenance reference materials must be provided.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Child Toy Kettle Body Mold Suppliers