USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

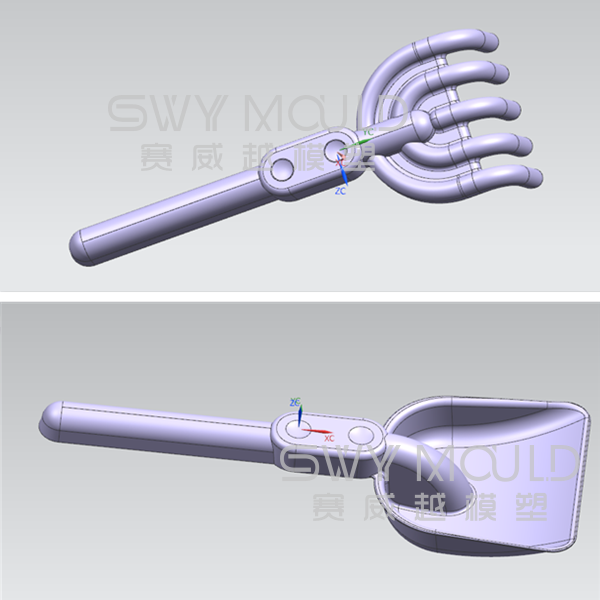

Shovel dimension: 250*90mm

Rake dimension: 230*90mm

Raw material: PP, food-grade

Mould steel: P20

Mould base: 60#

Nos of cavity: 2+2

Injection system: cold runner

Mould size: 675*400*400mm

Suitable machine: MA900 or MA1600

Aspects of judging the plastic beach sand toy rake injection mold quality

1. Injection molding plastic products quality

The dimensional stability and conformity of injection molding plastic products, the surface finish of injection molded parts, and the utilization rate of plastic molded parts materials, etc can reflect the quality of the injection mold itself.

2. Service life

Under the premise of ensuring the quality of plastic injection molded parts, the number of work cycles that injection mold can perform, or the number of plastic parts produced.

3. The usage and maintenance of injection mold

Whether it is most convenient to use, whether it is easy to demold, and whether the production auxiliary time can be as short as possible.

4. Maintenance cost, maintenance cycle

The time of the injection mold maintenance cycle and the cost of maintenance is also included in the assessment of the quality of injection mold.

How to improve plastic beach sand toy rake injection mold quality?

1. Injection mold design

* Injection molding plastic products design

Injection molding plastic products design should be reasonable, and the designer should consider the structure and technical requirements of plastic injection molded parts in combination with the feasibility and process performance of injection mold making.

* Mold steel selection

It requires not only to consider the regular quality requirements of plastic products and the mold steel cost, but also consider these factors, such as mold making, injection molding process, and injection molding cycle, etc. For example, the stamping die is mainly subjected to periodic loads, which may cause surface fatigue cracks and cause surface peeling. Therefore, mold materials with good surface roughness should be selected.

* Structure design of injection mold

The structure should be compact and easy to operate, and it guarantees that injection mold and its accessories can meet the corresponding mechanical properties.

2. Injection mold making

* The processing methods and processing precision in injection mold manufacturing will affect injection mold service life. The accuracy of each mold part will directly affect the entire assembly circumstance of the injection mold. In addition to the influence of the accuracy of the equipment itself, it is necessary to improve the processing methods of mold components and improve the technical level during mold grinding to improve the processing accuracy of mold components.

* Surface strengthening the main molding parts of injection molds. Improve the surface wear resistance of mold parts to better improve the quality of injection mold. For surface strengthening, different strengthening methods should be used according to the injection molds for different purposes.

3. The usage of injection mold

Proper installation and commissioning and the use of molds are just as important for injection mold quality. After all, injection mold is a tool for processing plastic products, and it is inevitable that there will be a loss. Therefore, we should carry out regular maintenance on injection mold. The guide pin, guide bush, and other mold parts with relative movement of injection mold should be filled with lubricating oil. For the molds such as forging mold, plastic mold, and die-casting mold, before plastic injection molding, Spray a lubricant or mold release agent onto the surface of the injection mold. Planned protective maintenance of the mold and data processing during the maintenance process can prevent mold defects in plastic molding and improve plastic molding efficiency.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Beach Sand Toy Rake Injection Mold Suppliers