USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

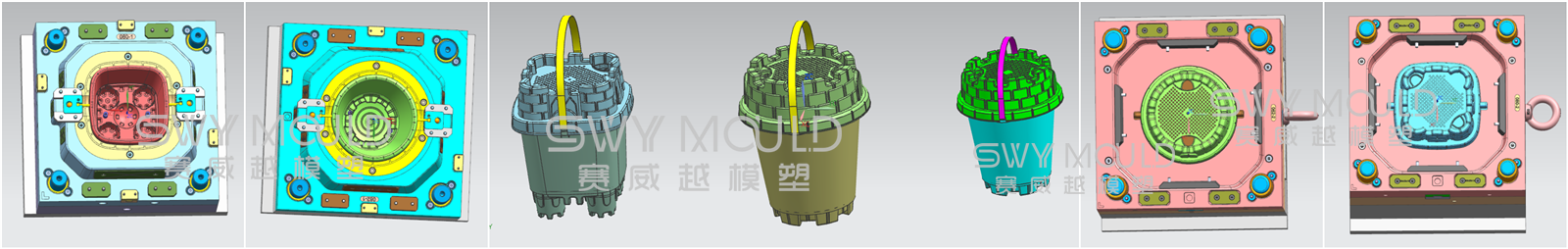

Bucket resin: PP

Part size: 160*160*160mm

Mould steel: 2344 vacuum hardening + beryllium copper

Mould base: 60#

Injection system: hot runner 1 drop

Mould size: 380*430*330mm

Mould weight: 360KG

Manufacturing method: HIGH-SPEED MACHINE 200T WITH ROBOT

Plastic kid sand container injection mould making process

As a good reputation manufacturer in China, SWY MOULD here shares the basic injection mould making process in our company:

1. Products design department provides product information to the injection mould design department, injection mould designers complete cost analysis in two working days, and provide it to the R&D manager.

2. R&D department released “Mould Making Apply” to the plastic injection mould design department after confirming the project.

3. Injection mould designers organize relevant personnel to review the project base on the product information, including product structure, mould structure, cooling system, runner, slag, venting, etc.

4. After evaluation, injection mould designers begin to design the plastic injection mould, including 3D drawing correction, 3D parting, mould parts assembly drawing, EDM drawing, electrode drawing, etc., and organize relevant personnel to evaluate those drawings, then issue to plastic injection mould making department.

5. Injection mould makers evaluate and study the drawings, and order mould materials if there is no objection, otherwise, communicate with the plastic injection mould designers.

6. Injection mould makers inspect the mould materials in time after the materials arrive in the factory, and arrange technicians to do locksmith works, including turning, grinding, milling, screw holes, water carrying hole, centre hole, CNC roughing, etc. The technicians should pay attention to the precision of each right-angle side, avoid empty of the centre hole and each production base, roughing margin, etc. Then outsource each mould part to heat treatment promptly.

7. After heat processing, the plastic injection mould maker must detect its hardness and metallurgical analysis. Generally, the core hardness is 46-50HRC, for uniform distribution of 9 points, requiring its hardness to differ is less than 1HRC. Metallurgical analysis should be done for the injection mould core prior to processing to make sure there is no segregation, scars, etc.

8. Electrode processing, there are fine and rough processing, the fine male spark is 0.08, the rough male spark is 0.2 (subject to the actual situation). Be sure to pay attention to each processing benchmark, and detect electrodes after processing is finished.

9. Before finishing must make a right angle for the mould core, the vertical degree should be less than 0.02 mm, finish degree 1.6.

10. For line cutting, please note that all parts’ base, enlarge 0.02mm for the insert hole and centre hole as tolerance clearance, for a non-standard thimble, the tolerance clearance is 0.04mm of the actual thimble size.

11. Mould core finishing, shall base on the benchmarks after making right-angles, typically leaving 0.02 mm die as a margin (without considering tool wearing).

12. EDM processing, process according to the drawings’ size, fine 0.08, rough 0.2 (subject to the actual situation), pay attention to the benchmarks in processing, for sparks processing, the leave a margin of 0.03-0.05 mm.

13. The runner surface must be polished to achieve ▽6 or ▽7 finishing, the surface does not allow spark or knife pattern exists.

14. Before assembling the plastic injection mould, the mould maker must do a comprehensive inspection of all related parts to make sure everything is in a good condition, and do cleaning and anti-rust treatment. Then fill “Mould Inspection Summary” form.

15. In tryout, injection mould designers, plastic mould makers, and die casting workshop personnel should go to the site, make analysis and solutions of abnormal in casting tryout, improve the plastic injection mould and die casting process according to the results, and fill “Mould Tryout Report”.

16. By 100-150 cycle time, the tryout products are defect-free, the production department makes the production schedule, the technicians track the production processes, and feedback yields to the plastic injection mould making department.

17. After the tryout, the plastic injection mould making department applies for storage with the forms of “Mould Making Apply” and “Mould Making Inspection”.

According to its past experience, SWY MOULD has established perfect management procedures and a quality guarantee system; expert technology of mould making and plastic mould products, advanced equipment for silk-screening, transfer-printing, surface coating, and so on. SWY has focused on quality, cost, and delivery. Our staff is committed to manufacturing quality products, on time, at competitive prices. Our success has been achieved by a combination of advanced technology, precision equipment, and qualified staff. These elements work together to accomplish our goal: high-quality products delivered on time. SWY’s primary business activities are the design and development of tools and plastic moulds, as well as mass injection moulding of plastic parts that are used in different industries. SWY MOULD provides top quality and complete business consultancy for all types of plastic manufacturing companies around the world. Whether you are looking to build a new business market, expand your existing business, or simply improve your current international business; SWY is prepared to help. We have great international experiences and we can’t wait to work for you!

SWY MOULD technical---design

What is a good mould? It must have good quality to meet production requests stable and smooth, and no need to spend too much time & cost on maintenance and repair.

A good mould design is a critical start. SWY has 6 designers in total with more than 10 years of experience, they always pay special attention to customers' specifications and details by thinking about the cost-saving solution based on stable and good quality. Their years’ experience in exporting moulds give them great knowledge of global mould standards and quality demands.

Software related:

Mould Flow: Mould Flow Analysis

3D Modeling: Pro/Engineer, Unigraphics, Solidworks

2D Drawing: Auto-CAD, E-drawing

The following international data format works OK for us:

2D drawing files: dwg, dxf, edrw

3D drawing files: step, Igs, X-T, prt, sldprt

The aspects of injection mould maintenance that are easy to ignore

The maintenance procedures required for each injection moulding location depend on different mould cycle cycles. The following are some general principles that can be used by each mould user to ensure the effective operation of mould components such as hot runners, heaters, guideposts, and thimbles to prevent accidents.

1. Check if there is an early warning of rust or moisture at the vent hole-if you find rust or moisture near the hot runner exhaust hole, it means that the internal condensation or the water pipe may be broken. Humidity can cause a fatal short circuit to the heater. If the machine does not run continuously throughout the year but shuts down at night or on weekends, the chance of such condensation will increase.

2. Remember to remind the operator not to "clean up" the hot nozzle at the gate – if the operator happens to see a small piece of stainless steel at the mould nozzle, it may actually be a nozzle component. "Cleaning up" this seemingly obstructive thing often ruins the hot mouth. In order not to damage the hot nozzle, please confirm the nozzle type of the lower hot runner system before taking action to ensure that all operators are well-trained and can recognize all the different types of nozzles they touch.

3. Sliding stop – For machines that run all year round, this work should be done once a week.

4. Cross-check the resistance value of the heater-You should have measured the resistance value of the heater when you first started using it. Now is the time to measure and compare it again. If the resistance value fluctuates by 10%, you should consider replacing the heater to ensure that it does not go wrong at a critical moment in the production process. If you have never measured the initial resistance value, measure it now and use the obtained value as reference data for future inspections of the heater.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mould Of Plastic Kid Sand Container Suppliers