USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Soft rubber resin: soft TPE (in the beginning, customer choose soft PVC, at last, changed to soft TPE, with consideration of environmental protection and safety)

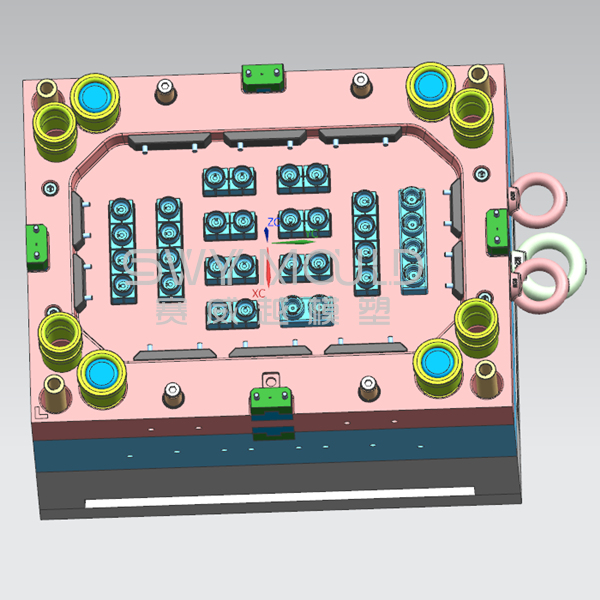

Part size: 127*31*34mm & 62*62*34mm

Mould material: S136

Mould cavity: 4+8

Runner system: cold runner

Ejector system: ejector pin + air ejector system

Mould size: 580*440*470mm

Mould weight: 800KG

Injection machine: MA1600 C SCROLL

The material used in this building block mould is TPE soft rubber, one of the common problems which meet is TPE sticking into the mould, so how to help product drop from mould is the most important thing. As our customer requires the mould must automatic, our SWY Mould manager has thought a while and decided to use a gas-assisted system to make sure the runner and building blocks can drop automatically and easily.

The air ejector system

Viewing our testing of this system in the mould:

Benefits of the air ejector system

1. Reduced cycle time

2. Reduced pressure and clamp force tonnage

3. Part consolidation with both thick and thin sections

The difficulty of making a good plastic building blocks mould is how to control all blocks can match with each other with the same strength and size. Every step of making this mould needs high attention.

How to ensure soft rubber building block injection mould quality?

1. Mould design

This mould consists of two size samples, and the length is different, so during the design process, how to make the material flow runner balance is important. Otherwise, the small samples are filled with material quicker than the big size one, which causes small samples with flash or big samples to be a short shot.

2. Mould machining

SWY Mould uses a high precision machine to process, also we require a specific person to control all building block moulds, won't let other workers operate the mould machining. After every machining finish, our manager will check the precision and mould, if not okay, return to machining again, if this step is okay, turn to the next step. SWY has a project manager to control all machining process.

3. Mould polishing

For the special plastic resin of TPE, if the mould polishing is too bright, the parts are easier stuck into the mould, SWY requires the polishing won't too bright, which making the resistance to make sure products drop automatically.

4. Mould assembly

Making sure the movement of all mould parts are smooth, the cavity and core part can fit well.

5. Mould testing

Not only make sure the products can be formed during testing but also making sure the testing need to know the better machine setting parameters. SWY Mould will test several more shots which need to simulate customer mass production to make sure mould is well after arriving at the customer factory.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Injection Mould Of Baby Soft Rubber Building Blocks Suppliers