USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Product usage: matching with wheels act like a car, which can increase the enjoyment of playing building blocks. As the second picture shows.

Product material: ABS

Mould steel: P20 with hardening treatment

Mould base: 60#

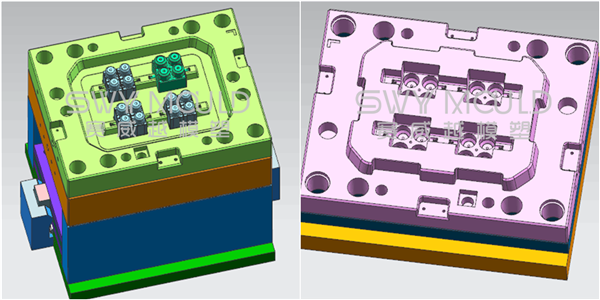

Mould cavity: four cavities

Runner type: cold runner

Ejector system: ejector pin

Surface finish: high-gloss polish

Mould size: 580*430*600mm

Mould weight(GW): 650KG

Mould life: 1,000,000 shots

Sample day: 45 days after design confirmed

Building blocks can help to develop children's intelligence and training their hand-eye coordination ability. Arranging, jointing, and stacking can help children building cognition of symmetry and proportion. Blocks are allowed to be arranged in different ways or for building activities, which helps children have better imagination and creativity. Some building blocks are made of wooden material. They are usually decorated with letters or pictures on each surface. Another type is made of plastic material, which can be produced in different colours. Compared with wooden material, plastic building blocks are at a reasonable price and long time usage. The wooden material will mildew but the plastic one won't. Also for some wooden blocks may have bits of wood that can scratch children's hands. Considering all, plastic building toy blocks is a good choice for children playing.

There are many shapes into one set of building blocks, so we advise customers if they need to order the moulds, it's better to give the total set of moulds into one company, so that can arrange the assembly and size tolerance. For building blocks, the most important thing is assembly, each one must assembly not too tight or not too loose with others. During every step in mould making, quality control is very important.

Quality control of every step in child building block mould making

1. Product design QC

Whatever product design made by SWY Mould or offered by customers, we always make all-round analysis and inspection, such as moulding process feasibility, mould structure and movement feasibility, all the related plastic components matching situation, etc. It can avoid mould amendment, scrap and other unnecessary mould repair work, which are caused by a product design fault. We believe that 10 more minutes we spend on the design, one month may be reduced in production.

2. Mould design QC

With precise analysis, foreseeing rationality analysis for mould design, best processing analysis and mould structure application, it offers the most professional solutions with the most suitable mould performance and technical specification as customer required. The inspection covers many aspects, such as mould intensity, mould-flow analysis, mould ejection, cooling system, the rationality of guiding system, application of mould spare parts' specification, customers' machine selection and special requirement application, etc.

3. Process machining QC

Control the size precisely, make self-inspection on each tooling spare parts according to the requirements of drawing size and tolerance limits control. Only past the inspection, can the spare parts delivered to the next working step. It is not allowed to make previous wrong workpiece inflow to the next tooling steps. For CNC milling, it needs strict auditing for procedures before tooling. After tooling, we will check up and control the precision by 3D coordinate measures. We have many measures: professional tooling technology training and machine maintenance; self-inspection of tooling workpiece and acceptance check made by quality department; rational work shifts system and tooling control system.

4. Quality inspection of mould installation

Make complete inspection on the mould to ensure the structure consistency and spare parts standardized. The project manager and QC people should all take part in mould inspection under the company standard, and make sure the product quality. If mistakes are found, they can be corrected promptly. It also can prevent mistakes. In addition, we will simultaneously do independent standardization test on the mould cooling system, mould hydraulic oil channel system and hot runner system.

5. Mould testing's acceptance check

To some extent, our mould testing aims at finding the quality problems of mould, while not cover the problems. Thus, we have many steps in mould testing, including dry running, high-pressure bearing, high-speed injection and necessary long time mould injection inspection.

Viewing our moulds testing video:

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Child Building Blocks Mould Manufacturers