USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

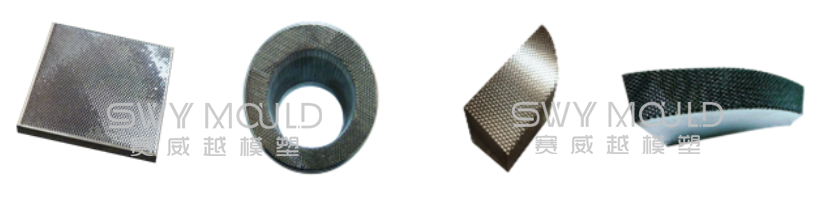

There are different types of reflex electroform mold insert, such as flat standard electroform and customized electroform.

Flat standard electroform: Square plate: 100x100mm

Rectangular plate:140*80mm

Customized electroform: Curve Surface Reflex Electroform

Ring Shape Reflex Electroform

Back Plate Processing

Our design team is able to build the corresponding electroforming 3D model or complete mold data according to the 3D CAD or 2D Drawing of the product. SWY MOULD provides the service to make mold insert and complete mold.

Knowledge about reflex electroform mold insert

Reflectors are used in the rear lamps fixed to vehicles, bicycles, highway delineates, industrial sensors, and so on. Reflector molds require precision work and special technology and knowledge of optics, so it's a hard job for some mold companies.

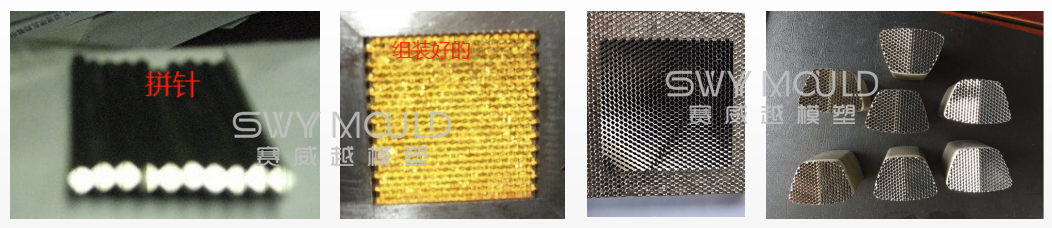

The core of a reflector mold is made of bound hexagonal pins whose heads are mirror-polished in a 3-D triple mirror. High precision is required for the angle of the finished surfaces. The core of the mold for the reflectors of 3-D curved surfaces like the rear lamps of vehicles is made of electroformed, which is formed from a pin-bound master.

The types of the reflex electroform mold insert

1. Flat type (or slightly curve): the axle of the car and the optical axis is coaxial, reflex exposed, wall thickness within 1.5mm.

2. Curve type, inner type (with outer lens)

3. Inclined surface, large curvature, or the wall thickness is too large.

The process of making reflex electroform mold insert

1. Machining the needle---5 days

2. Assembling the template---5 days

3. Electroform---around 35 days

4. According to product wire cutting, then assembly---around 7 days

Points need to be noted about producing reflex electroform mold insert

1. The polishing degree of female die(cavity side)

* Reflector belongs to optical grade reflective product. Regardless of any type or any condition, in the surface of products and outer lens of the lamp, the requirements of mold material and mirror polishing process are very important.

* We advise that mold material of female die should use P5 grade and above, BPMHH2738C or the high nickel and high hardness steel will be better!

* The polishing of female die should be made by Hand-applied to ensure it's smooth and accurate. And the polishing should up to # 3000 or more.

2. Waterway design

The design should be as close to the reflex electroform, it will be better if the range is bigger and more uniform.

3. Air vent

The mold design should contain the air vent, in case of bad forming.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Reflex Electroform Mold Insert Manufacturers