USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part resin: soft TPU, hardness 85

Material drying: 4 hours with 100 degree

Mold cavity: 2

Runner system: cold runner

Cycle time: around 60 seconds

Injection machine tonnage: 160T

Mold size: 380*220*260mm

Mold weight: 120KG

Attention points of this TPU car steering rack bush injection mold during production

As the raw material is soft TPU, it's soft and easily sticks to the mold, so during mass production, SWY MOULD advises the cooling time should be longer so that the product won't be easily stuck with mold.

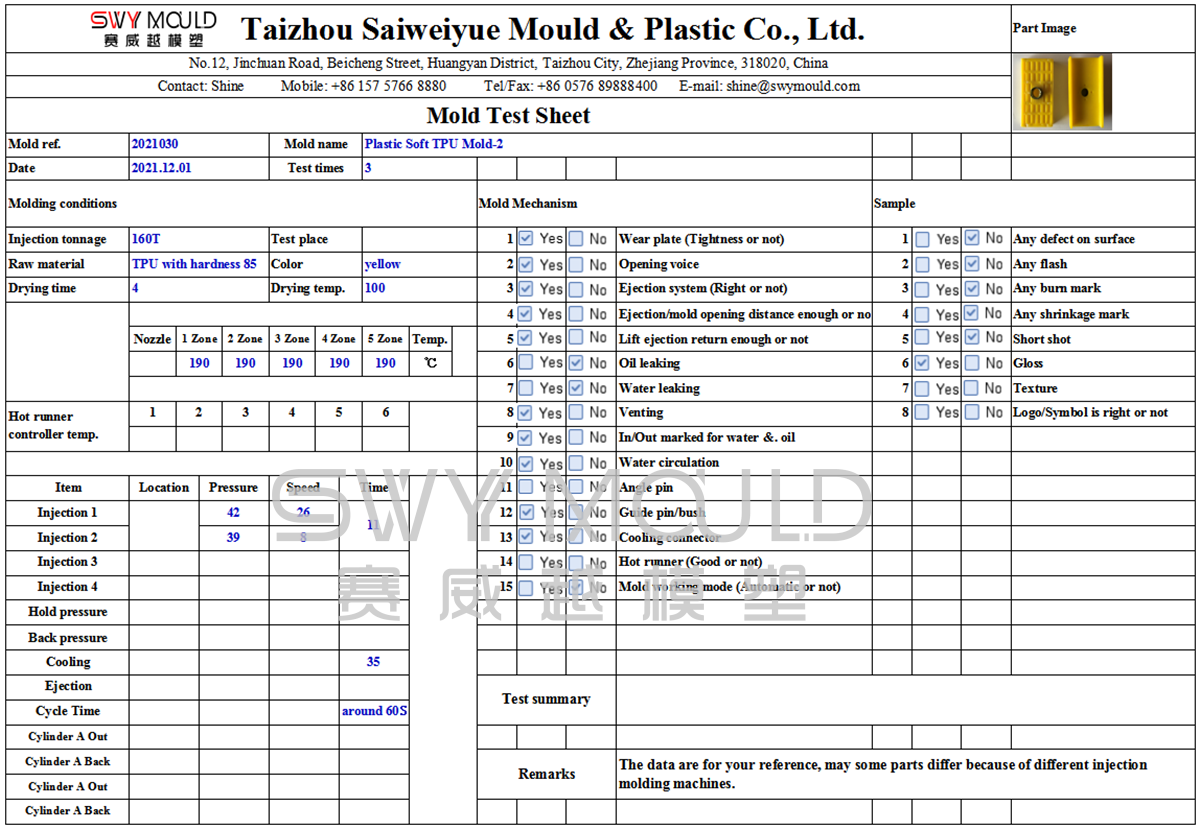

For every mold, SWY will send our customers the Mold Test Sheet for reference. We record all the data during mold testing, such as injection pressure, injection speed, cooling time, etc. Later before mold shipment, we will fill the following chart, print it out, and send it with mold.

Later if our customers have any problem with mold production, it's very welcome to contact us.

Ways of solving TPU stick on injection mold

Sometimes the customers are not professional in setting machine parameters, and there is the easiest way---printing the mold release agent. Before every shot, print some agents and then close mold and injection.

Another way is to treat with Teflon. Teflon is the name for polytetrafluoroethylene (PTFE). PTFE coated molds are a groundbreaking approach that helps in the easy demolding of the molded item. The inner surface of the PTFE coated molds is smooth and allows the item to be molded with more accuracy in design and dimensional requirements. Also, any cracks due to the irregularities in the surface of mold are right away eliminated by the PTFE coating. The negligible chemical reactivity of the coating protects the mold from corrosion occurring due to continuous use with different material types.

Mainly gray in color, the coating may be of black, green, red, or various other colors as per the specifications conveyed to the manufacturer. As you can see our mold, it's green and differs from other molds. It's treated at a high temperature and special machines. No matter how many shots you produced, the TPU material won't stick to the mold. It's the most effective way for mass production.

Insert injection molding of TPU mould

To meet assembly and service strength requirements, TPU molded parts need to be embedded with metal plug-ins.

Metal inserts are first placed in a predetermined position in the mold and then injected throughout the product. Due to the great difference in thermal performance and shrinkage between metal inserts and TPU, TPU products with inserts cannot be firmly bonded together. The solution is to preheat the metal insert, because after preheating will lower melt temperature, thus make the melt around the insert can slow cooling, and shrinkage in injection process is relatively uniform and has a certain effect of hot material feed might happen this kind of situation, in order to prevent excessive internal stress around the blade.

TPU is easy to Mosaic and the Mosaic shape is not limited. After degreasing the inlay only, heat 1 at 200-230℃. The peel strength can reach 6-9kg / 25mm within 5-2 minutes. To obtain a stronger bond, an adhesive can be applied to the insert, which is then heated at 120℃ and injected. In addition, it should be noted that the TPU used should not contain lubricants.

Recycling of recycled material

During TPU processing, waste such as the main channel, shunt channel, and unqualified products can be recycled. According to the experimental results, 100% recycled materials can be fully utilized without adding new materials, and the mechanical properties will not be seriously reduced. However, in order to keep the physical and mechanical properties and injection conditions at the optimal level, the proportion of recycled materials is recommended to be 25% ~ 30%.

It should be noted that the types and specifications of recycled and new materials should be the same. Contaminated or annealed recycled materials shall not be used. Recycled materials should not be stored for too long. It is better to granulate and dry immediately.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Soft TPU Plastic Injection Metal Insert Mould Suppliers