USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part size: 270*336*170mm

Part raw material: PP

Function: OEM

Sample: customer provided

Mould design: SWY provided

Mould outer size: 570*670*700mm

Fixed/Moving plate steel: 2316

Runner: unitary hot runner with brand

Core pulling: side core pulling with angle slider & spring

Cycle time: 18-20 seconds

Mould features: multi-slider movement, high precision and balanced test passed

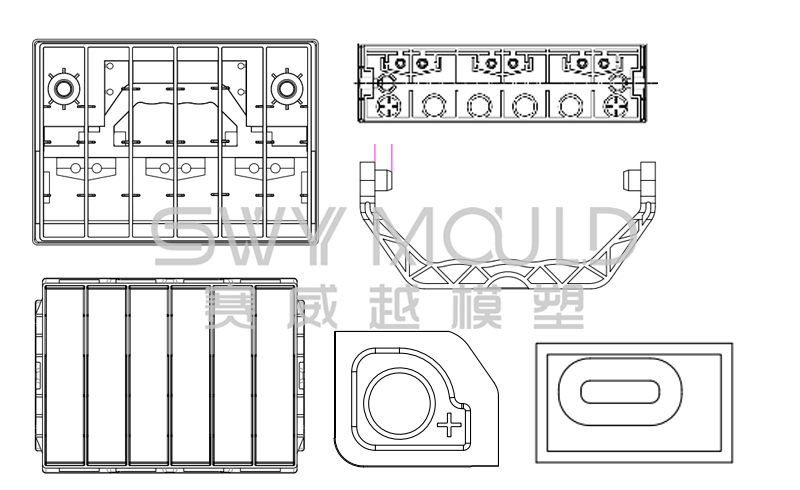

This set of battery container mould, including not only a body mould but also, have cover mould, handle mould, button mould. It's better to order a set of moulds into one mould making company, so that can easy for product size adjustment. See the below pictures for your reference:

At present, there are several different types of batteries, like the lead-acid battery, Li-ion battery, UPS battery, etc. We choose a suitable battery type and suitable battery model based on certain working conditions and requirement. The battery outer container is made by the plastic injection moulding, usually, we use PP, ABS, FR-ABS as the raw material, which is insulated and able to bear high voltage testing.

The battery box moulds we made before including automotive battery series N40, N50, N70, N100, N120, N150, and N200; UPS battery series like 55AH, 90AH, 100AH; Invertor battery series like IT 500; DIN battery series like DIN55, DIN66; And any other types of plastic battery case mould making according to customer requirement.

How to control each lattice size is the same?

This is crucial for mould production, it can’t be too loose or too tight. If it is too loose, the battery case will expand when charging; if it is too tight, the battery case will not be charged. Therefore, after more than 20 years of experience, our company has found the best solution for controlling the size. Our engineers will first perform a mould flow to analyze the deformation of the battery case. According to this report, our designers will choose the appropriate injection point position to maintain the injection balance. In addition, our mould waterway design is very dense, in order to achieve good cooling.

Battery box mould technical points

1. Designed with 7tips hot runner system for balance injection, gate diameter chooses according to mould flow analysis - the side two tips and middle five tips with different diameter.

2. Precision tooling to realize accuracy dimension control.

3. Use higher hardness steel for the 6 pcs core inserts to avoid any bending or core shifting.

4. Mature assembling teamwork for completing the whole set mould.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Car Battery Box Mould Suppliers