USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Raw material: PA66+GF30

Part size: 418.5*77.5*38mm

418.5*77.5*60mm

Mould cavity: 1+1

Cavity/core steel: 718

Mould base: C50

Runner system: cold runner

Mould size: 870*580*420mm

Mould weight: 1680KG

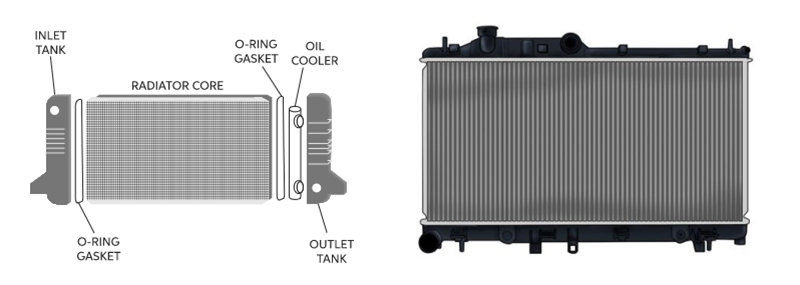

What is an automotive water cooling tank?

The automotive water cooling tank is a cooling system for cars. It is mainly a large water tank. The water tank is divided into upper and lower water chambers. The upper and lower water chambers are two halves. The upper half is stamped and the lower half is stamped. Welding, riveting the end cap of the water chamber with a rubber pad, is a complete water tank.

The working principle of automotive water cooling tank

1. In the radiator, the pump present pushes the coolant, which is of normal temperature towards the automobile's engine.

2. When the vehicle is in an ON state, the engine produces large amounts of heat, absorbed by the coolant. Then, the hot coolant is sent to the radiator to be cooled and then sent back to the engine.

3. When the heated coolant reaches the radiator, it is passed through a series of pipes to cool down.

4. There is air present in the radiator which is used to cool down the coolant.

5. This process continues till the time engine is in an ON state.

6. In case the radiator is not present then the engine will be overheated and not work properly.

The raw material of automotive water cooling tank---PA66+GF

By adding glass fiber, nylon flexibility, etc, the mechanical properties of blend materials results show that with the increase of the glass fiber content, the material of a dramatic increase in tensile strength, bending strength, the impact strength is stronger, toughening agents to join, the toughness of the material greatly improved, adding 30% ~ 35% glass fiber, 8% ~ 12% of toughening agent, the comprehensive mechanics performance of the material is the best.

Application fields of PA66+GF

Compared with the pure PA66, the mechanical performance of PA66+GF is greatly improved, which makes PA66+GF more widely applied in the automotive industry, such as cylinder head cover, engine seat and total cover, door handle, lock system, wheel decoration, automobile lock handle, ashtray, switch, etc.

The thermal deformation temperature of PA66+GF increased from 70℃ to above 220℃, and the aging resistance was significantly improved. Can be safely used in the automotive, mechanical, chemical, and other fields, the manufacture of heat-resistant structure components, such as automotive pressure regulating tank, air intake manifold, throttle body radiator tank, fan blade cover, and other components.

The shrinkage rate of PA66 filled with glass fiber decreased from 1.5%~1.8% to 0.2%~0.3%, which makes nylon 66 products smooth without warping and more stable in size. It is widely used in gear, coil skeleton, and other precision parts.

The corrosion resistance of PA66+GF has also been significantly improved, which can meet the service requirements of automobile radiator groove, the middle part of radiator bracket, water inlet pipe fitting, oil pan, filling tank, oil level, automobile water chamber, etc. Compared with the pure PA66, the glass fiber enhances the PA66, and the mechanical strength, rigidity, heat resistance, creep resistance, and fatigue resistance are greatly improved.

As mentioned above, PA66+GF has high strength, good heat resistance, electrical performance, abrasion resistance, high impact resistance, as well as advantages such as simple processing method, low production cost, high efficiency, economic and environmental protection. It has expanded the application space of nylon 66 products in automobiles, electronic appliances, and also widely used in high-end application fields such as mechanical components, shields, fan blades, automotive cooling water tanks, gears, coil frames, roller belt covers, chain guides, window insulation profiles and so on.

The molding process of automotive water cooling tank mould

1. The molding process of glass fiber is roughly the same as that before reinforcement, but the flow is worse than before reinforcement, so the injection pressure and injection speed should be appropriately increased, and the temperature of the injection molding machine barrel should be increased by 10-40℃.

2. In the process of injection molding, the glass fiber will be oriented along the flow direction, resulting in the enhancement of mechanical properties and shrinkage in the orientation direction, resulting in product deformation and warping. Therefore, when the mold is designed, the location and shape of the sprue should be reasonable.

3. In addition, the larger the proportion of glass fiber, the greater the wear of plastic components of the injection molding machine, it is best to use a bimetal screw, cylinder.

The feedback from SWY MOULD customer

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Automotive Water Cooling Tank Injection Mould Suppliers