USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part size: 108*620*78mm

Part material: PA66+GF30

Insert material: 1.2344 HRC48~52

Cavity number: 1+1

Injection system: 2 drops INCO hot nozzles

Cycle time: 45S

Design time: 15 workdays

Manufacture time: 50workdays

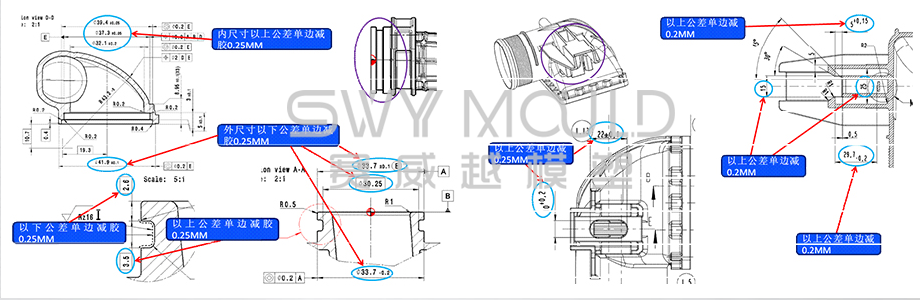

Plastic automobile water chamber product characters

1. Automotive exterior plastic injection mold for water radiator tank

2. Flatness control for the part

3. Roundness control for the tube with tolerance +/-0.1 mm

4. Straightness control for the connector with just 1-degree tolerance

5. Slow flow rate engineering nylon resin with 5VA grade fireproof

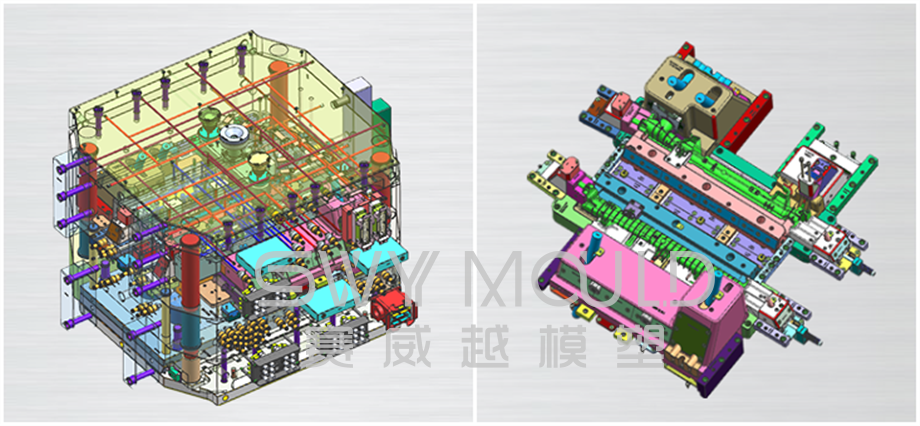

Plastic automobile water chamber injection molding design

The customer provides the 2D or 3D drawings in DXF, DWG, PRT, SAT, IGES, STEP format, etc, or just sends us the sample. We will scan the sample and make a product blueprint, begin to design the mold assembly drawing after the customer's confirmation and customize the existing projects.

SWY adopted an international advanced system - CAD/CAM/CAE in mold design and injection molding.

Our engineering and mold-making technology includes:

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. Catia

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM's (Electro-Discharge Machining)

9. Wire-Cut Machines

Considerations for choosing hot runner systems

For plastic automobile water chamber mold, a hot runner for the injection system is one of the important points we must consider.

1. Injection pressure

The plastic that’s found inside a hot runner has to stay hot, and this means that the internal pressure has to drop.

2. Gate type

Being able to use a wide range of gates. Consider the gate marks, the location, and the materials that are compatible with that particular gate when choosing to go with a hot runner over a cold runner. For instance, crystalline thermoplastics require mold gate designs that are different from what non-crystalline plastics will need.

3. Runner size

The runner size will impact the general performance. If missing out on this factor, there is a risk of plague with the degradation of the plastic components.

Advantages to making mold with a hot runner system

1. Hot runner has a very fast cycle time to separate the plates from the products.

2. Quality and consistency in the components of the product being made.

3. It is the best option for larger parts.

The quality control system in SWY MOULD

SWY MOULD regards “Quality” as the vitality of our company, it is a guarantee for company development. We are strictly working based on the following procedures to guarantee our quality:

1. Incoming quality control

All materials and components are checked upon delivery to ensure they meet the project requirement. The related certificate for steel, mold base, raw plastic material will be provided upon request.

2. In-Process quality control

For mold making, every component or part will be checked at every manufacturing process before releasing to the next step. Injection production stage, we have quality checking through the whole manufacturing process. The main quality control equipment will be a vision measuring machine and the Coordinate Measuring Machine.

3. Final quality control

Before shipping every mold, we will perform a final quality checking for the key points to ensure there is no step is overlooked.

4. Sample measurement report

We will provide sample measurement after the first try out using customer-provided 2D part drawing and we could provide a CMM report also upon request.

We could provide a fully CMM steel measurement report for the cavity, core, and other main inserts as per request.

Welcome to contact SWY MOULD to get your customized plastic automobile water chamber injection mold.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Automobile Water Chamber Injection Molding Suppliers