USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: PA66+30%GF

Mold steel: P20

Mold base: SC50

Mold size: 1+1

Injection system: cold runner

Mold size: 900*540*440mm

Mold weight: 1290KG

Suited machine: 470T

What is a plastic car radiator tank?

Engines create a lot of heat in their operations - they’re powered off of miniature explosives! To prevent your engine from overheating, your car pumps coolant through your engine - the fluid that receives heat and carries it away from the engine block. The coolant takes the heat generated by your engine and moves it to your radiator, which blows air across the liquid - cooling it down and exchanging heat with the air outside your car.

The radiator works bypassing your coolant through thin metal fins, which allow the heat to flow to the air outside your car much more easily. Sometimes, there is a fan that blows air across the radiator in order to carry the hot air out of your car. Radiators come in many different shapes, sizes, and designs, but their primary function remains the same.

In essence - a radiator cools the coolant, which then cools your engine.

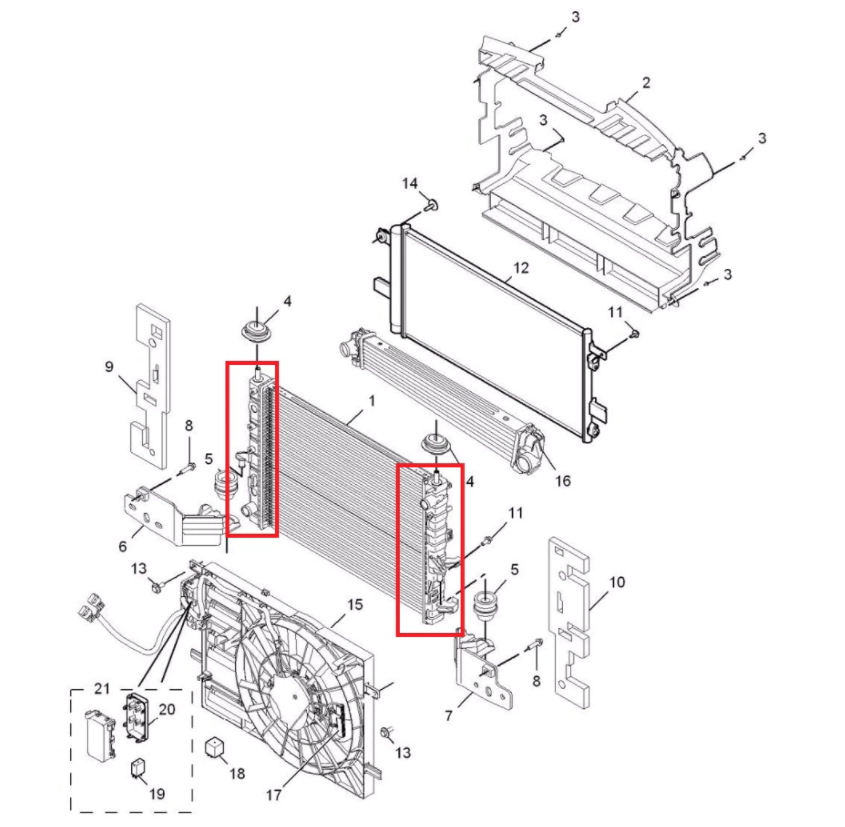

The red part is just the product we made:

The plastic resin of the plastic car radiator tank---PA66+30%GF

PA66 GF30 is a 30 % glass fiber reinforced PA 66. It demonstrates outstanding mechanical properties such as higher strength, rigidity, creep strength, and dimensional stability. Compared to unreinforced PA 66, the properties of this glass-filled modification GF30 make this material suitable for use in parts that are exposed to high static loads over long periods in high-temperature conditions. As glass fibers tend in some cases to have a marked abrasive effect on mating surfaces, Nylon 66 GF30 is less suitable for sliding applications. Due to its black color additives, the black Nylon 66 GF30 shows improved UV protection for outdoor weather resistance applications.

1. The material is used in:

* Electrotechnical industry

* Automobile industry

* Engineering industry

* Paper industry

* Production of single-purpose machines

2. Features:

* very high stiffness

* resistant to many oils, greases, and fuels

* good wear properties

* very high strength

* high dimensional stability

* good weldable and bondable

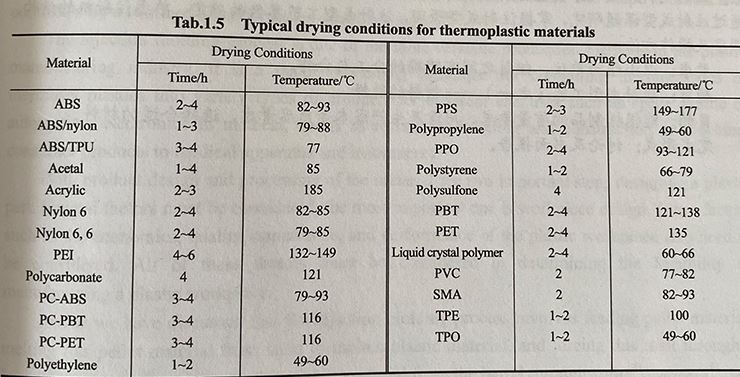

Drying plastic resin for testing mold

Why do some polymer materials need to be dried before injection molding? The chemical structure of a particular polymer determines whether it will absorb moisture due to its polar chemical structure. A number of polymers such as polystyrene, polyethylene, polyvinyl chloride, and polypropylene are nonhygroscopic for their nonpolar chemical structures and do not absorb moisture. However, due to their more complex chemistry, materials such as polycarbonate(PC), acrylonitrile-butadiene-styrene(ABS)terpolymers, PC-ABs blends, nylon, thermoplastic polyurethanes, polyesters, and polymethylmethacrylate(PMMA)are hygroscopic and absorb moisture a problem arises at the polymer processing temperature which can exceed 200C boil off the water at 100C in the polymer that is hygroscopic polymer materials.

The effect that water on a molded workpiece may appear on the surface because the bubbles generated from the boiling of the moisture get trapped in the polymer, then cool, and solidify in the mold. This creates bring on the defect as water reaction such as polycarbonate and nylon-based materials, those splay marko or siherssmaky. On the surface, troubleshooting tends to reduce its physical and mechanical properties. The results in reversing the polymer-forming reaction in the polymer, leading to chain scission or depolymerization can make a polymer difficult, if not impossible, to process to obtain the desired product.

Hygroscopic material can absorb more moisture from the air than other plastic resins can. The hygroscopic volume of the pellet is determined by the resin type, the ambient relative humidity and time, and will reach a moisture balance point with the surrounding environment. For example, ABS is usually 0.3%, whereas nylon is typically 0. 15%. It is very important to remove moisture not only from the pellet's exterior surface but from the interior of the pellet as well for the drying plastics materials process. There are four steps to driven moisture off the materials. The first is heating Heat can drive the moisture to the surface of the pellet. The second is airflow that acts as"besom" to sweep the moisture away from the surface of beads. The third is dry air that acts as a"sponge" or recipient to remove the moisture of the pellet surface. The fourth is the time which affects drying to take place. All of these steps are important in drying which will greatly affect plastic materials properly. The delivery of air to the hopper must be as that it can absorb water from the moist pellets. The drier the air, the more effective it will be in extracting moisture from the resin. Following lists typical drying conditions for thermoplastic materials.

About our SWY MOULD

1. Where?

If you have bought molds from China, you will know that there is a place here in Taizhou City, Zhejiang Province. Everyone calls it "the Mould Town", and our factory is also here. If you have recently come to Taizhou to buy moulds, we sincerely invite you to visit the factory. Saiweiyue Mould Address: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China. We sincerely look forward to your visiting!

2. Who?

Taizhou Saiweiyue Mould & Plastic Co., Ltd was established in 2015. Although it is just a start-up, we believe that the future is expected.

Today, we already have customers in America, Argentina, Brazil, Ecuador, Egypt, India, Iran, Macedonia, Mexico, Pakistan, Peru, Singapore, Sri Lanka, Spain, Sudan, etc., and our molds have been well received by customers.

3. Which?

We mainly make injection molds, such as auto parts molds, household parts molds, home appliance parts molds, industrial parts molds, child products molds, thin-wall products molds, medical products molds, pipe fitting, and blowing molds, etc.

4. How?

If you want to cooperate with SWY MOULD, please send us more information for mold quotation:

* Sample photo with size

* Product design (3D)

* Requirements for molds or products

This information is more conducive to us providing a professional quotation and some professional advice for the mold you need.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM PA66+30%GF Plastic Car Radiator Tank Mold Suppliers