USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Part raw material: PA6

Mold steel: cavity-413

core-413+beryllium copper

Mold base: P20

Cavity: 1+1+1+1

Injection system: cold runner

Suitable machine: 200T

Eight sliders, fully automatically drop and double ejection

The preparation before ordering the plastic auto windscreen wiper mould

The first step of mould order is making the quotation. Our customer from Argentina sent us an email with sample pictures and his requirements. With such detailed information, we can give him reasonable mould price and mould analysis reports. After some discussion, our customer sent us the original sample by DHL, so that we can begin mould design and mould making.

The feedback from our customer

Repeated orders are decided by good mould quality and nice service.

Our customer is satisfied with our moulds, and send us more samples to make new moulds.

Mould temperature control with beryllium copper cooling system

Since mould temperature has a strong influence on the molding cycle and the quality of molded parts, the method of controlling mold temperature must be investigated beforehand as carefully as other parameters of mold design, such as runners, gates, and knockout methods. The following points should be considered in the design of mold temperature control.

1. A hot water circulation system is more favorable than a system employing heaters.

* Provide sufficient heat transfer area for mold cooling channels (many wide cooling channels).

* Bring the cooling channel as close as possible to the cavities. (If the cooling channel is far from the cavities, surface temperature distribution becomes wide.)

* Provide a sufficient quantity of circulation water. (Use a temperature controller which pumps a large volume and has a pumping pressure that exceeds the pressure loss in the water channel.)

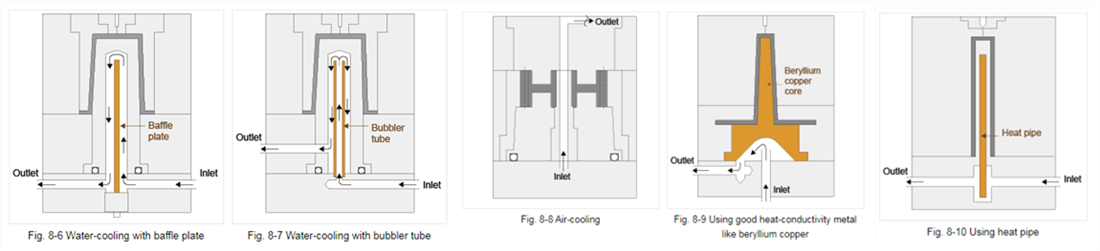

2. Consider the employment of core cooling. (Since heat tends to accumulate in the core section, along molding cycle is required if cooling is not sufficient.)

* Water-cooling examples are shown in Figs. 8-6 and 8-7.

* Air-cooling example is shown in Fig. 8-8.

* Cooling by good heat-conductivity metal is shown in Fig. 8-9.

* Cooling by heat pipe is shown in Fig. 8-10.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Plastic Auto Windshield Wiper Manufacturers