USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Plastic resin: PA6

Drying time: 6-8 hours with 90-100℃

Cavity steel: 413

Core steel: 413+beryllium copper

Mold base: P20

Mold cavity: 1+1+1+1

Injection system: cold runner

Suited machine: 168T

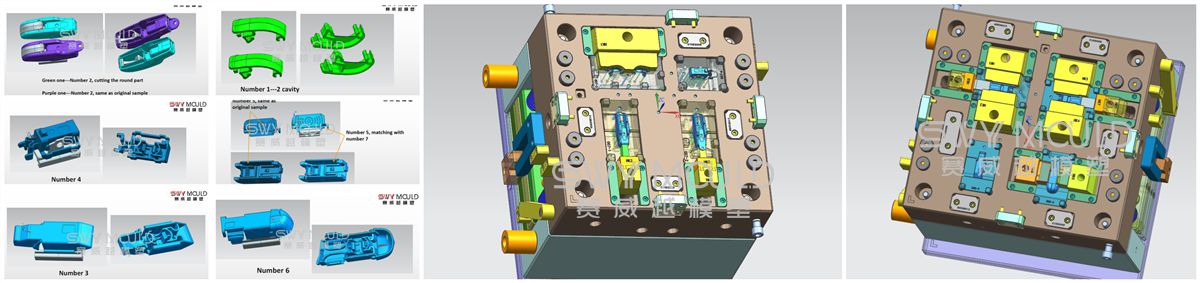

Sample analysis of automotive plastic windscreen wiper adapter matrices

First, the customer wants to make one mold with a total of 8 samples, but after analyzing all samples, we advise him not to make them into one mold. The samples are small with complex structures inside, if making into one mold, the mold will be complex and large, not good for mass production.

After discussion, we advise our customer to make two molds, each mold with 4 different samples. Also, we will make the material flow runner switch to control the production, later we will explain the function of this switch.

The material flow runner switch in mold

It's a control switch in plastic mold, which suits different cavity molds, you can control the producing cavity by yourself. If you don't want to produce more of this kind of product, you can close the material flow runner, when producing, the material won't flow into that cavity, but you still can produce other products.

Kindly check our testing video, we will show you how the switch works.

The mold design process in SWY MOULD

We provide engineering guidance to help you design moldable parts that are optimized for manufacture. From tool design concepts to process development and validation, we ensure that all aspects of production meet the ultimate goal of producing high-quality injection molded parts.

1. Product design assistance

Support in the design of product features, specs, and industrial design follow. We can support you in the development of your new projects or re-design current products and implement these steps on behalf of clients by meeting in person and teleconferencing with you and your sales & marketing and technical people each step of the way.

2. Product development Mold design support

Early Stage Engineering Support Mold drawing 2D

Quality Requirement Planning Mold drawing 3D

Material Selection Consultation Design for Manufacturable

Mold Concept Planning Mold Design Checked

Part Optimizing Mold Design Specification

Design For Manufacturing Mold Design Optimized

Cycle Time Optimization Cooling Design Optimization

How to maintain automotive plastic windscreen wiper adapter matrices?

1. Recording

The working state of the mold is usually recorded in detail. Statistics on the use and care of the mold (lubrication, cleaning, rust prevention) and damage. Based on this, you can find out which parts and components are damaged and the degree of wear.

To provide information on the discovery and problem-solving, as well as the molding process parameters of the mold and the materials used in the product. In order to shorten the production time of the mold, improve production efficiency and ensure the positive life of the mold.

2. Testing

The company should test the various properties of the Injection mold under the normal operation of the injection molding machine and the mold and measure the size of the final molded part. This information can be used to determine the current state of the mold and identify damage to the cavity, core, cooling system, and parting surface.

According to the information provided by the plastic parts the damage state of the plastic injection mold and the measures for maintenance can be judged.

3. Tracking detection

Focus on the detection of several important parts of the plastic mold:

The function of the ejection and guiding parts is to ensure the opening and closing movement of the mold and the ejection of the plastic parts. If any part of it gets stuck due to damage, it will lead to a production stoppage. Therefore, the thimble and guidepost of the mold should be kept regularly (the most suitable lubricant should be selected), and regularly check the thimble, guide column, etc. for deformation and surface damage. Once found, it should be replaced in time.

After completing a production cycle, apply professional anti-rust oil to the working surface, movement, and guiding parts of the mold. In particular, the protection of the elastic strength of the bearing parts with gears and racks and the spring mold should be emphasized to ensure that they are always in top working condition.

The cooling channel is easy to deposit scale, rust, sludge, and algae, which makes the cooling channel section smaller and the cooling channel narrows. Greatly reduce the heat exchange rate between the coolant and the mold, increasing the production cost of the enterprise. Therefore, the cleaning of the flow channel should be paid attention to.

For hot runner molds, the maintenance of the heating and control system is beneficial to prevent production failures, so it is especially important. Therefore, after the end of each production cycle, the ohmmeter should be measured with the band heater, rod heater, heating probe, and thermocouple on the mold. If there is damage, it should be replaced in time and compared with the mold resume make a record, in order to find problems in a timely manner, take countermeasures.

4. Clean up

Pay attention to the surface maintenance of the mold, which directly affects the surface quality of the product, The focus is on preventing corrosion. Therefore, it is especially important to choose a suitable, high-quality, professional anti-rust oil. After the mold has completed the production task, the residual injection molding should be carefully removed according to different injection molding methods.

Use copper rods, copper wire, and a professional mold cleaning agent to remove residual injection molding and other deposits in the mold, then air dry. Disable the cleaning of hard objects such as wire and steel bars to avoid scratching the surface.

If there is rust caused by corrosive injection molding, use a grinder to grind and polish, and spray professional anti-rust oil. Then store the plastic injection mold in a dry, cool, dust-free place.

Features of automotive plastic parts mold

The automotive parts mold refers to the series of plastic molds that are produced for manufacturing parts that are used in cars. Automotive parts mold is a blanket term that encompasses all sorts of molding which includes injection molding, stamp die, forging die, etc. this means that they would be involved with the entire range of molds that are used in the manufacturing of cars.

* They are typically light in weight when compared to metal auto parts

* The durability level is as good as or even more than the other metal parts

* The parts can be made fairly quickly once the mold is designed

* It is possible to make even functional and multi-functional pieces

* It can produce the best results when it is done with a fair knowledge about the qualities of plastic and how they behave when subject to heat-treatment

However, choosing the right mold and the right company for mold making would ensure efficiency and cost-effectiveness.

Welcome to contact our SWY MOULD, we would like to tell you more about automotive plastic parts mold.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Automotive Plastic Wind Wiper Adapter Matrices Suppliers