USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Usually, there are many diameters of this kind of pipe, such as 12mm, 16mm, etc, and different thicknesses. Also, there are many other irrigation items, such as drip tape, arrow dripper, sprinkler, venturi, filter, air valve, pressure regulator, hydraulic reducing valve, etc.

Kindly provide us with your samples and contact SWY MOULD to get a more detailed quotation on plastic injection moulds.

The function of this drip irrigation pipe:

Feeding of the plant's daily water needs (together with nutrients) drips by drip to the root of plant or earth surface utilizing a system that filters the water and carries it through lateral pipes.

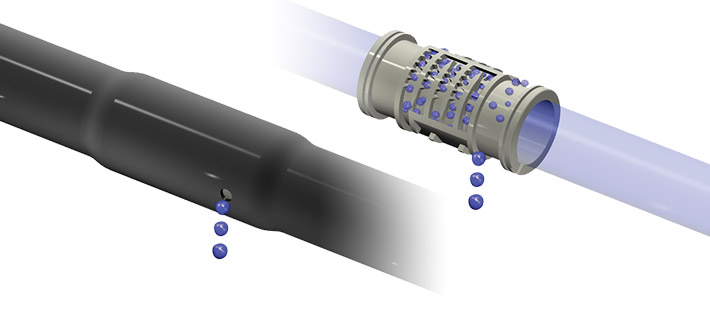

How does the drip irrigation pipe work?

Inside the drip irrigation pipes, “drippers” in equal ranges, and these are integrated with a pipe. Flowing under a defined pressure throughout the pipe, water is taken under control by having it circulated in the channels on the surface of these drippers and it drips exactly to the root of plants with a time interval allowed by drippers (flow rate control).

Advantages of drip irrigation pipe

1. With the use of drip irrigation pipes, water loss is minimized.

2. Drippers that are placed in certain intervals inside the pipe sustain water to be fed to the plant root at desired amounts.

3. Furthermore, with this method, water-soluble fertilizers are also fed to the plant root together with water.

4. In agriculture where conventional irrigation methods are applied, plant strikes so many roots to reach the water; however, since water is directly fed to the plant root in the drip irrigation system, so plant does not strike so many roots and therefore the force is fed to the product, not root.

5. Since the drip irrigation system lowers the moisture in the air, it substantially prevents fungus diseases.

6. Provides 60% saving comparing to conventional irrigation methods.

In order to control the water volume dripped, the size of this pipe must precision. So for mould making, size control is very important.

What is plastic precision injection moulding?

Normally tolerance on the plastic moulding part is around 0.05-0.1mm, if the part tolerance requirement is about 0.01-0.03mm, that means this is precision plastic injection moulding, to make high precision plastic injection moulding parts, the first thing is making the precision injection mould, all of the mould components must have tolerance within 0.005-0.01mm, this is min requirement for high precision plastic injection mould after the mould is completed finished, then take mould trial to verify the dimension according to 2D drawing requirement, to trial the mould and make stable tolerance, precision plastic injection mould is number one key point to making high precision moulding parts, but not limited to this, you still need use high precision injection moulding machine to produce the part, by this two min requirement we can make sure that we can make precision molding parts continually, there are few issues that we make still need to know for the precision plastic injection moulding.

The points need to concerns about plastic precision injection moulding

1. The determination of the structure of the precision plastic mold is the key, and the overall structure is the embodiment of the final effect of the product.

2. Choosing a reasonable injection scheme according to the structure, weight, volume, and cost of the product, which can meet the requirements of customers as well as the requirements of quality. Then, designing in strict accordance with the injection design standards: the layout of the runner should be uniform, especially the size of the cross load surface of the main and sub runner, the shape and size of the gate.

3. Determining the ejection mode according to product orientation and structure. Then, evaluating the ejection balance and coexist with other systems, such as interference with water transportation and recycling marks, date clock, etc.

4. The design of the water channel system is based on four requirements (the cooling line should be as balanced as possible. The water cooling line shall not interfere with other mechanisms. The water channel equipment shall meet the customer’s standards and be easy to install. Each water channel line shall be displayed with identification numbers or marks (in and out).

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. OEM/ODM Precision Drip Irrigation Pipe Mould Suppliers